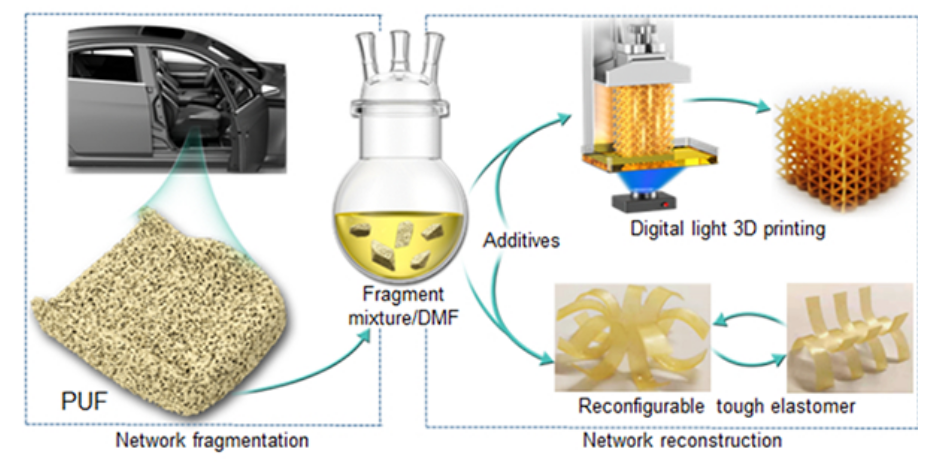

With funding from the National Natural Science Foundation of China (Grant No. 52033009) and other projects, Professor Xie Tao’s team from the School of Chemical Engineering and Bioengineering at Zhejiang University reported a method that combines efficient degradation of commercial thermosetting polyurethane foam with high value A new chemical recycling strategy for chemical utilization can degrade polyurethane foam into polymer fragments. By designing end-capping chemistry, high-performance 3D printing resins with high added value can be obtained. This strategy has mild degradation conditions and can obtain high-value products with excellent properties without purification. It has both economic and environmental benefits. The relevant results are “Chemical appreciation recycling of thermosetting polyurethane foam into high-performance 3D printing resin”

upcycling of commodity thermoset polyurethane foams towards high-performance 3D

Photo-printing resins)”, published online in “Nature Chemistry” on August 28, 2023

Chemistry) magazine.

Polyurethane foam is widely used in the manufacture of car seats, furniture mattresses, anti-collision padding, insulation materials, etc. due to its many advantages such as adjustable softness and hardness and convenient production. Currently, the annual global production of polyurethane foam has exceeded 12 million tons (the volume is approximately 400 million cubic meters), and the generation of large amounts of waste has also caused serious environmental problems. The traditional method is mainly through incineration or landfill, causing secondary pollution of the environment and waste of resources; while the economic added value of the products obtained from physical recycling and chemical recycling is low, and there is no prospect of industrial application. Therefore, the recycling of thermosetting polyurethane is a worldwide problem that needs to be solved urgently in the field of science and technology.

Commercial polyurethane foam is mainly prepared by reacting diisocyanate with polyol (or polyamine) and using water as the blowing agent. First, we used small molecule model experiments to study the dissociation mechanism and reaction kinetics of urea bonds, urethane bonds, and biuret as dynamic bonds in polyurethane foam. Further, we soaked the crushed polyurethane foam in a dimethylformamide (DMF) solution containing 1,5,7-triazabicyclo[4.4.0]dec-5-ene (TBD) as an organic base catalyst. in 120

After heating for 20 minutes at °C, the sample can be completely dissolved and non-cross-linked polymer fragments containing active hydrogen at the end groups are obtained. Chemical modification of this polymer fragment can be used for photocurable 3D printing. With the help of dynamic chemical bonds in the network, the printed single polymer network can be reconstructed into an interpenetrating double network during the thermal post-curing process, solving the common contradiction between photo-curing printing and the final properties of the cured product, thereby achieving high-performance 3D Print products.

The recycling of polymer waste usually includes two strategies: product reprocessing and degradation and recovery of monomers. This work rationally utilizes the “intermediate state” between the finished product and the monomer to construct new high value-added materials using partially degraded polymer fragments as raw materials. This idea can be extended to other systems, providing a new way for chemical recycling of commercial thermoset materials.

微信扫一扫打赏

微信扫一扫打赏