The air filter is a key equipment in the purification air conditioning system. Through the step-by-step filtration of the filter, clean air is provided for the clean room. Its performance directly affects the air purification effect of the purification air conditioning system and the cleanliness level of the room. Therefore, the purification air conditioning system must use appropriate air filters and ensure its reliable operation.

Air filters can be classified according to the following indicators:

1. According to filtration efficiency: primary efficiency, medium efficiency, sub-high efficiency and high efficiency filters. In foreign classifications, a medium-efficiency filter is subdivided between medium-efficiency and sub-high-efficiency filters. After the high-efficiency filter, there is an ultra-high-efficiency filter. Since the chance of daily contact is very small, we will not introduce it in detail here. .

Primary filter: generally used for fresh air filtration. The filter objects are generally sedimentation particles larger than 5 microns and various foreign matter. The filter element generally adopts plate type, folding type, wedge-shaped bag type and automatic winding type.

Medium-efficiency filter: Generally, it can be used as a pre-filter for the high-efficiency filter in the purification air-conditioning system to extend the life of the high-efficiency filter. The filter objects are generally suspended particles of 1-10 microns. The filter element generally adopts insert plate type, wedge-shaped bag type, plate type and folding type.

Sub-high-efficiency filter: It can be used as a final filter in a clean room or as a pre-filter for high-efficiency filters in purification air-conditioning systems. device to further improve and ensure the cleanliness of the air supply. Mainly used to intercept particles below 1 micron. The filter element generally uses glass fiber filter paper, cotton short fiber filter paper, etc.

High-efficiency filter: Generally used as the end filter of the clean room to ensure that the air supply meets relevant cleanliness requirements. Mainly used to intercept particles below 1 micron. Filter elements generally use glass fiber filter paper, asbestos fiber filter paper, synthetic fiber, etc.

2. According to structure: Yes With and without partitions.

Partitioned filter: The filter element is made by folding the filter material back and forth according to the required depth, and is supported by corrugated partitions between the folded filter materials to form an air channel for filtration. device.

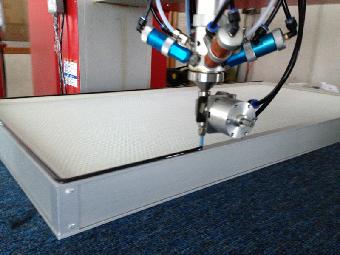

Partitionless filter: The filter element is made by folding the filter material back and forth according to the required depth, and is supported by linear adhesive or other objects between the folded filter materials to form air Channel filter.

3. According to the sealing method with the external structure: solid gasket seal, liquid tank seal and negative pressure leakage seal.

Solid gasket seal: An elastic solid gasket is pasted around the filter, such as neoprene rubber, closed-cell sponge rubber plate, etc., to achieve sealing between the contact surfaces by squeezing with force.

Liquid tank seal: The frame of the liquid tank seal filter is equipped with a groove, and the groove is filled with non-Newtonian sealing fluid. During installation, insert the knife edge into the non-Newtonian sealing liquid in the groove for sealing. The principle of action is similar to that of a pickle jar. This sealing method is stable and reliable, with less leakage, and is widely used in clean rooms with higher purification levels.

Negative pressure leakage seal: Strictly speaking, this sealing method is not determined by the filter, but by the equipment and installation location where the filter is installed. The principle of this sealing method is to use the filtered space at the downstream end of the filter as positive pressure and the unfiltered space as negative pressure to solve the sealing problem between the filter and the external structure from the structural design. FFU and tunnel ovens generally adopt this type of sealing method.

4. According to the degree of temperature resistance: ordinary filters and high temperature resistant filters.

High-temperature resistant filters use high-temperature glue to bond the filter element and frame of the filter. They are mainly used in high-temperature equipment such as dry heat sterilization cabinets and tunnel ovens.

The air filter is a key equipment in the purification air conditioning system. Through the step-by-step filtration of the filter, clean air is provided for the clean room. Its performance directly affects the air purification effect of the purification air conditioning system and the cleanliness level of the room. Therefore, the purification air conditioning system must use appropriate air filters and ensure its reliable operation.

2. Performance parameters of the filter

1. Filtration efficiency

Filtration efficiency: refers to the air content before and after being filtered by the filter under the rated air volume. The ratio of the difference in dust concentration to the dust concentration in the air before filtering, expressed as a percentage.

2. Thickness series: 46, 69, 79, 90, 96, 150, 220, 290, etc. (mm).

3. Dimensions and rated air volume

4. Initial resistance

Initial resistance: refers to the pressure before and after the new filter when it passes through the rated air volume. static pressure difference.

This initial resistance is a relatively important parameter. In daily work, we generally judge whether the filter needs to be replaced based on the resistance of the filter. When the final resistance of the filter reaches twice the initial resistance, it means that the filter is “very dirty” and it is recommended to replace it; when the final resistance drops significantly, it means that the filter is damaged and needs to be replaced immediately.

5. Filter dust holding capacity

Filter dust holding capacity: refers to the maximum allowable dust accumulation capacity of the filter. Generally speaking, the dust holding capacity of the filter refers to the amount of dust accumulated when the resistance due to dust accumulation reaches a specified value (generally 2 times the initial force) under a certain air volume.

For example: the initial force of a high-efficiency filter is 200Pa. Dust continues to accumulate during use until the resistance value reaches 400Pa. At this time, the amount of dust held by the filter is� is the dust holding capacity of the filter.

This content is provided by Shanghai Wellgo Chemical Industry. For more industry information, please log in to: www.wellgo.com.cn.

微信扫一扫打赏

微信扫一扫打赏