On November 7, Ricoh Co., Ltd. announced that containers made of Ricoh’s new plant material PLAiR foam sheet will be sold to Ito-Yokado Co., Ltd.

Starting November 16, Ito-Yokado Yokohama Bessho store (Yokohama City, Kanagawa Prefecture) will begin selling food in these containers. (Ito-Yokado was founded in 1920 and is affiliated to SEVEN, Japan’s largest retail giant.

& i Group. )

The container will be used for the tonkatsu rice bowl, marking the first time a container using polylactic acid (PLAiR) has been put on store shelves. This sheet for molding and processing was developed using Ricoh’s proprietary foaming control technology. Although it is a material that is 99% derived from natural sources, it contains an air layer due to foaming and therefore has excellent thermal insulation properties. . In addition, by controlling the degree of crystallization, it is heat-resistant and can be heated in a microwave just like a traditional tonkatsu rice container.

In recent years, as climate change and environmental pollution from waste have become social issues, switching from fossil resource plastics to alternative materials has become increasingly important. Ricoh regards the realization of a decarbonized and recycling society as an important social issue, and as one of its solutions, we are developing PLAIR as an alternative material. So far we have verified

PLAiR has the potential to be used in a variety of applications, from cushioning and packaging materials to processed products such as containers.

Ito-Yokado has been working to solve the plastic problem through eco-friendly containers made from recycled and biomaterials. Ito-Yokado has been considering the use of materials that can further reduce environmental impact and has now decided to use polylactic acid (PLAiR) for demonstration experiments.

In addition to Ito-Yokado and Ricoh, Vendor Service Co., which has advantages in providing raw materials such as containers and ingredients for the retail industry,

Ltd. and Rispack Co., Ltd., which specializes in the development and manufacturing of bioplastic food containers, are also involved in the development and supply of PLAiR molded sheets.

Features of “PLAiR”

99% naturally derived

The main ingredient is PLA (polylactic acid), which is derived from plants and has compostable properties. This means that, for example, when incineration is performed, CO2 is emitted during the incineration, but the raw material plants absorb the CO2 during their growth, forming a cycle with less impact on the environment. In addition, it is compostable and decomposes into water and carbon dioxide under certain conditions.

Excellent insulation and heat resistance

“PLAiR” has excellent insulation properties due to the air layer formed by foaming. Even when placing hot food in a container made of PLAiR, you can hold it in your hand. It is also suitable for refrigeration and keeping warm.

“PLAiR” can provide excellent heat resistance by controlling crystallinity. Even in the heat resistance test at 120°C for 10 minutes, no visible deformation was observed. It can also be used for hot meals and heated in the microwave.

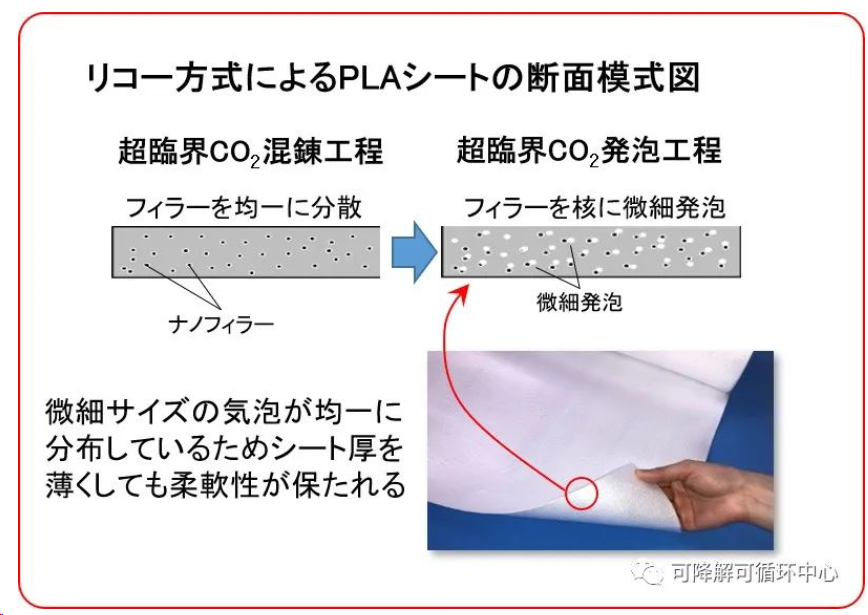

Unique foaming control technology

“PLAiR” is made by foaming plant-derived PLA using Ricoh’s proprietary “supercritical CO2 foaming control technology” and adjusts its flexibility and strength to achieve lightness and strength, making it suitable for a variety of uses. Additionally, by foaming, sheets can be made with less material, making it an excellent resource-saving material.

Technical Features

Due to the characteristics of PLA, it is difficult to foam using conventional foaming methods, and it has always been necessary to combine it with fossil-derived resins. Even with this method, the bubbles are difficult to control and vary greatly. The diameter of the bubbles can reach hundreds of microns, and the sheet is easy to tear. Furthermore, in order to add fossilized resin, one had to sacrifice

PLA is carbon neutral and compostable.

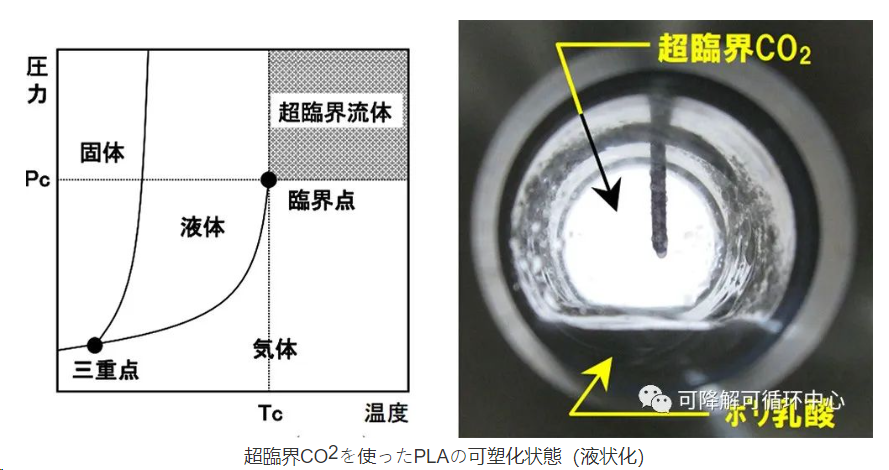

Ricoh uses supercritical CO2 during the processing. During the mixing process, the filler (foaming nucleating agent) is evenly dispersed in the PLA, and the filler is used as the core for foaming, successfully creating uniform bubbles in the order of tens of microns. Therefore, evenly foamed

PLA remains flexible even when made into thin sheets.

When CO2 is pressurized at high temperatures, it changes into a state called a supercritical fluid. It is in an extremely dense gaseous state (a highly concentrated vapor comparable to a liquid), with violent collisions between molecules, causing natural convection. By adding PLA and fillers to this gas, it is possible to achieve uniform mixing. By foaming with this evenly dispersed filler as the core, uniform and fine foam can be produced.

微信扫一扫打赏

微信扫一扫打赏