The anti-reflective coating (ARC) industry has broad development prospects. BARC is the mainstream product in the market.

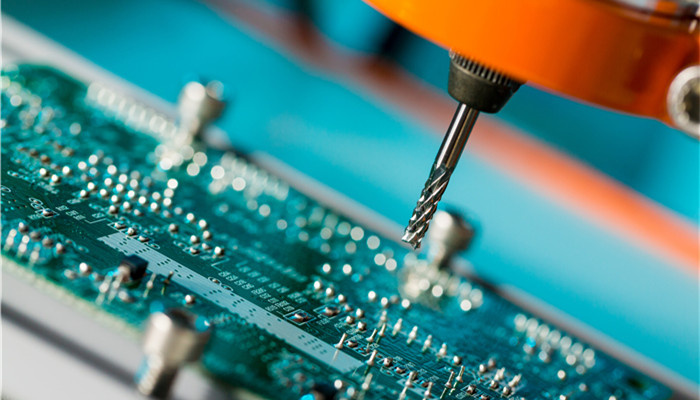

Anti-Reflection Coating, or ARC for short, refers to a substance that is spin-coated on the interface between photoresist and Si substrate to absorb photoreflected light. In the photolithography process, the wafer substrate is generally glass or metal. This type of substrate has a certain light reflection effect, which will cause interference between the incident light and the reflected light, causing a standing wave effect in the photoresist, thereby causing The side walls of the resist pattern appear wavy, which affects the normal execution of subsequent processes. Therefore, in order to avoid such a situation, it is necessary to add an anti-reflective coating to the photoresist to reduce the impact of reflection and improve the pattern fineness after photolithography.

Depending on the coating location, anti-reflective coatings can be divided into two categories: bottom anti-reflective coating (BARC) located between the Si substrate and photoresist and top anti-reflective coating (TARC) located on top of the photoresist. . The main components of TARC include fluoroalkyl sulfonate, fluorine-containing acrylic resin, anion activator, etc., which can only control the reflectivity of the photoresist surface and cannot suppress the reflection at the photoresist/substrate interface; the main components of BARC Including cross-linked resin, thermal acid generator, surfactant, etc., it has the advantages of large reflection control interface and good reflection improvement effect. It is currently the most widely used ARC.

Anti-reflective coatings are mainly used in photolithography processes and are used in conjunction with photoresists (such as KrF photoresist, ArF photoresist, etc.). End application areas include semiconductors, integrated circuits, display panels, etc. Currently, driven by the rapid development of the downstream market, the market demand for anti-reflective coatings is increasing. According to the“2023-2028 Anti-Reflective Coating (ARC) Industry Market In-depth Research and Investment Prospect Forecast Analysis Report” released by the Industrial Research Center It shows that the global anti-reflective coating market size in 2022 will be approximately US$310 million.

Globally, anti-reflective coating manufacturers mainly include international manufacturers such as Merck Group of the United States, DuPont of the United States, Honeywell of the United States, Brewer Science of the United States, Kumho of South Korea, Dongjin Semicon of South Korea, TOKYO of Japan, and Nissan Chemical of Japan. As well as Fujian Hongguang Semiconductor Materials, Shanghai Core Engraving Micro Materials Technology, Suzhou Runbang Semiconductor Materials, Shenzhen Shoucheng New Materials, Beijing Kehua Microelectronics Materials, Shanghai Xinyang Semiconductor Materials, Ningbo Nanda Optoelectronic Materials, Gansu Hualong Core Materials, Chinese companies such as TPV Display Technology.

Industrial analysts personnel said that anti-reflective coating is one of the materials required for the photolithography process. Its main Used in conjunction with photoresist, it can absorb or interfere with reflected light, eliminate standing wave effects, and reduce reflection effects. In recent years, its market demand has continued to grow, and the industry has shown a good development trend. There are a large number of anti-reflective coating manufacturers in the world. At present, the market is still dominated by international companies that started earlier and have relatively mature technologies. Chinese companies are still at a disadvantage in market competition and need to continue to increase technology research and development in the future.

微信扫一扫打赏

微信扫一扫打赏