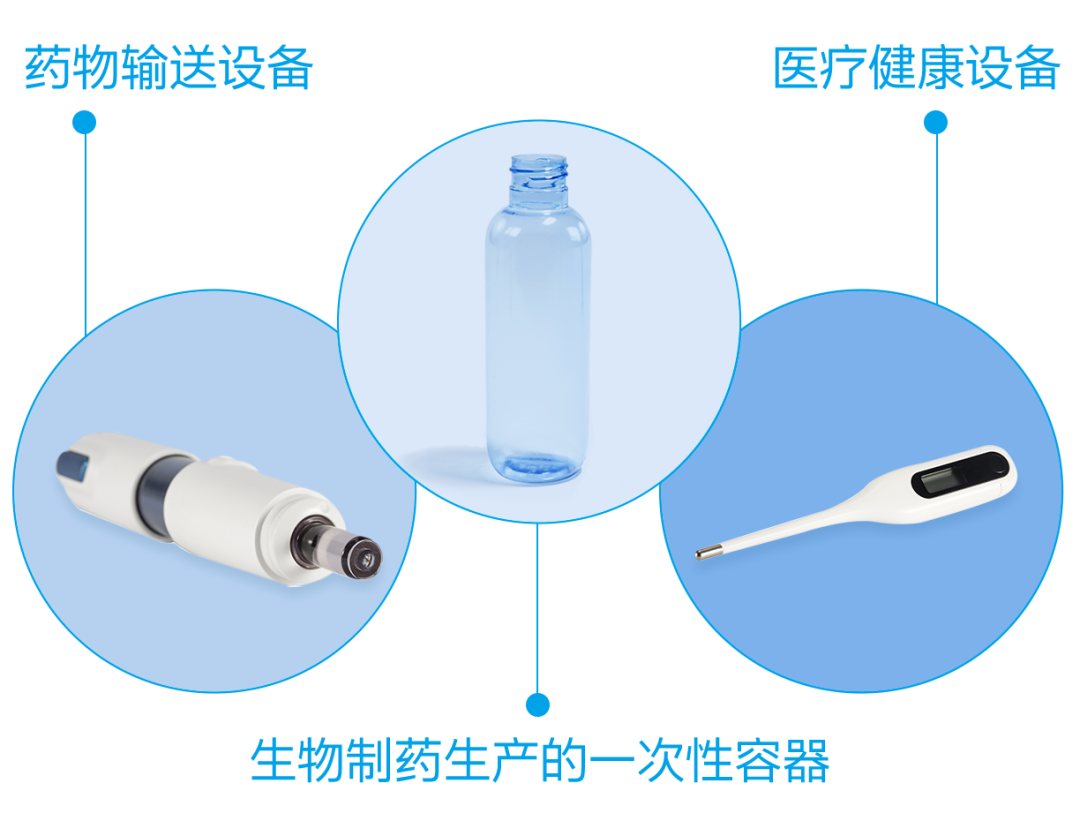

With the rapid development of medical technology, the market has also put forward higher requirements for the materials of medical equipment. In the application of various medical equipment such as drug delivery and wearable health equipment, these materials need to be more comprehensive. Durable and structurally sound. To address these challenges, Covestro launched Makrolon® 3638 polycarbonate material to help the healthcare and life sciences markets develop a new generation of innovative devices with a combination of high performance.

Makrolon® 3638 polycarbonate is a new material that meets strict standards. It not only has significant impact resistance and chemical resistance, but also performs well in terms of environmental protection.

Remarkable impact resistance, no fear of daily harsh environments

In daily use, medical equipment often faces harsh environments and “uncontrolled” conditions, such as high-intensity impacts, sudden drops, extremely low transportation temperatures, etc., which place greater demands on the robustness and ductility of the equipment. High demands.

Covestro Makrolon® 3638

The polycarbonate material is endowed with stronger impact resistance from the beginning of the design and can withstand the impact strength caused by harsh handling or falling from high places, ensuring a long life cycle of the equipment.

Makrolon® 3638 polycarbonate often meets stringent standards for biopharmaceutical containers

Maintains performance over a wide temperature range

Even at very low temperatures, Makrolon® 3638

Polycarbonate also exhibits high impact strength and excellent ductility, making it durable under low temperature and steam sterilization conditions. The material’s unique combination of properties allows it to meet stringent standards over a wide temperature range, maintaining structural integrity when exposed to high impact and temperature stress.

Excellent chemical resistance, both durable and safe

In the medical industry, chemical resistance is also an important criterion for testing device performance. Makrolon® 3638

Polycarbonate not only has the characteristics of high transparency, but also meets biocompatibility standards*, meeting the market’s requirements for medical devices to be transparent, beautiful and safe. In addition, chemical resistance to daily chemicals such as skin lotions and hand creams has been increased to provide users with a clean, comfortable and long-lasting product experience.

Makrolon® 3638 polycarbonate can be used in both disposable and durable equipment

At the same time, the material is manufactured in compliance with GMP standards ISO 9001

Produced in certified factories and sold globally, it is a high-performance medical device material that has been proven safe in mature markets.

*According to international ISO 10993 or Chinese national standard GB/T 16886

Biocompatibility stipulates that materials in contact with intact human skin need to pass biological evaluations of cytotoxicity, skin sensitization and irritation to avoid situations or safety issues that may affect the user experience. Wearable devices that may be exposed to daily chemicals have higher requirements on the chemical resistance of their shell materials, because intolerant materials may cause damage and cracking of the shell.

Forward-looking sustainable design,helping achieve circular economy

Makrolon® 3638

Polycarbonate enables circular business models by supporting closed- and open-loop recycling, and comprehensive recycling also contributes to climate neutrality and the protection of natural resources and the environment. Based on the material’s unique combination of properties, it can also help manufacturers successfully transform innovative ideas into medical devices that can be mass-produced.

Covestro’s global resource portfolio advantages and product supply capabilities enable it to provide customers in different regions with safe and consistent quality materials. In China and the entire Asia-Pacific region, Covestro continues to improve its polycarbonate production capacity and localized R&D capabilities to ensure production and supply capacity to meet the growing market demand for high-quality polycarbonate.

Key performance advantages of Makrolon® 3638 polycarbonate

■ Durability: Ultra-durable from cryogenic freezing to steam sterilization, with high impact strength and ductility

■ Chemical Resistance: Best-in-class resistance to everyday chemicals

■ Limited Medical Grade Materials: Biocompatibility tested to USP Class VI, ISO 10993-5 and ISO 10993-10

standards and meet skin contact application requirements

■ Food Contact Compliant: Suitable for certain food contact applications

■ Sterilizable: Supports the most common sterilization methods in the healthcare industry

■ Design Freedom:��For rugged, transparent yet attractive applications

■ Processability: Stable and efficient processing performance, suitable for injection molding and blow molding processes

微信扫一扫打赏

微信扫一扫打赏