On November 21, Weiyuan Co., Ltd. announced that the 600,000 tons/year propane dehydrogenation unit has recently completed all processes, produced qualified products, and entered the trial production stage.

After the unit reaches capacity, it will add 600,000 tons of propylene and 24,600 tons of hydrogen annually. Propylene products can be used as raw materials for existing phenol acetone devices and the 300,000 tons/year direct oxidation propylene oxide device under construction. The commissioning of the project has further extended the company’s industrial chain, achieved independent supply of raw material propylene, and improved the quality of raw materials. Convenience, security and economy of supply.

Weiyuan Shares 600,000 tons/year PDH project

In August 2021, Weiyuan Chemical issued a stock prospectus and raised funds for investment projects including “600,000 tons of propane dehydrogenation and 400,000 tons/year high-performance polypropylene project”. It plans to use 2.243 billion yuan to raise funds. The total engineer of this project With an investment of 5.228 billion yuan, after completion, the company will have a propylene production capacity of 600,000 tons/year. In addition to being used for polypropylene production, the remaining part can basically independently provide raw materials for phenol and acetone plants.

On March 1 this year, Weiyuan Shares issued an “announcement on adjusting the production capacity scale of some fundraising projects and investing the remaining funds raised in some fundraising projects into other fundraising projects.”

The original “600,000 tons/year propane dehydrogenation and 400,000 tons/year high-performance polypropylene project” will be adjusted to “600,000 tons/year propane dehydrogenation and 200,000 tons/year high-performance polypropylene project”, and at the same time, The remaining funds raised from other projects will be invested in the adjusted PDH project.

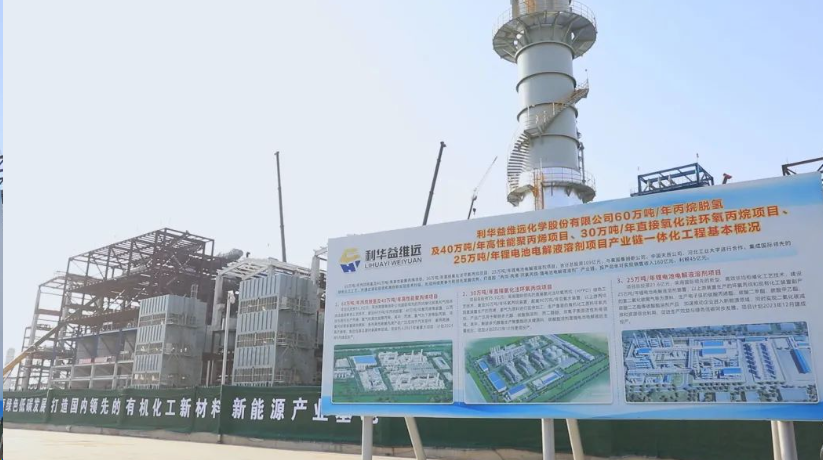

It is reported that the project adopts Lummus Company’s Catofin propane dehydrogenation technology process. Compared with other process routes, this technology has the advantages of high propylene selectivity, high conversion rate, and low unit consumption of raw material propane. The project will start construction in 2021, and a groundbreaking ceremony will be held on February 28, 2022.

The basic situation before the project adjustment is as follows:

Project name: 600,000 tons/year propane dehydrogenation and 400,000 tons/year high-performance polypropylene project;

Construction unit: Lihua Yiweiyuan Chemical Co., Ltd.;

Construction nature:New construction;

Construction location and land area: North Industrial Park, Lijin County, Shandong Province, east of Jiner Road, between Lishi Road and Lijie Road; area of 422,813.3m2

Project investment: The total investment is 5,736.6 million yuan, and the environmental protection investment is 242 million yuan;

Construction content: It will mainly build one 600,000-ton/year propane dehydrogenation unit and two 200,000-ton/year high-performance polypropylene units. The propane dehydrogenation unit uses propane as raw material and has an annual output of 600,000 tons of propylene (of which 402,000 tons are used as raw materials for polypropylene and 198,000 tons are used as raw materials for the phenol acetone unit); the scale and process of the two sets of high-performance polypropylene units are exactly the same. The annual output of 32 brands of polypropylene products is 400,000 tons.

Lihua Yiweiyuan Chemical Co., Ltd.

The company was established on December 23, 2010, and is mainly engaged in the production and sales of phenol, acetone, bisphenol A, polycarbonate, isopropyl alcohol and other products.

The company has completed and put into production production capacity of 350,000 tons/year phenol acetone, 240,000 tons/year bisphenol A, 130,000 tons/year non-phosgene polycarbonate, and 100,000 tons/year isopropyl alcohol. It is the first domestic company with ” An enterprise with full products and whole industrial chain including phenol, acetone-bisphenol A-polycarbonate.

Recent PDH Project Updates

Zhongjing Petrochemical: 1 million tons of PDH unit delivered

On the morning of October 31, Zhongjing Petrochemical’s second-phase propane dehydrogenation project with an annual output of 1 million tons held a handover ceremony, marking the completion of the installation, acceptance and delivery of the second-phase propane dehydrogenation project of Zhongjing Petrochemical, which was a smooth success. Enter the debugging preparation stage before production. The project is scheduled to be officially put into production in December this year.

Sinochem International: 600,000 tons PDH unit commissioned and commissioned

On October 29, good news came from Sinochem Lianyungang Circular Economy Industrial Park. The propane dehydrogenation (PDH) unit with an annual output of 600,000 tons of Sinochem International’s Carbon III Project has been put into trial operation recently and is expected to produce qualified products in early November. This marks the completion of Sinochem International’s Lianyungang epoxy resin industry chain integrated device.

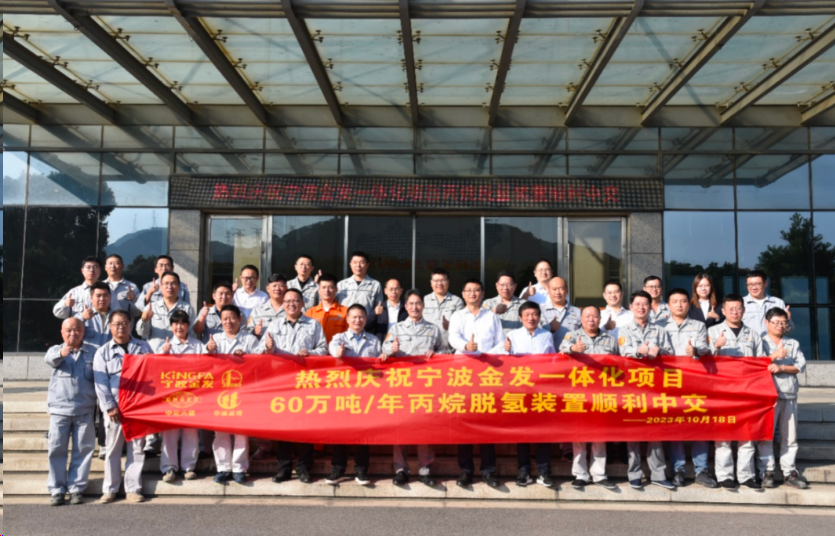

Fafa Technology: 600,000 tons/year PDH CCCC

On October 18, Ningbo Jinfa Integrated Project ushered in an important milestone – the 600,000 tons/year propane dehydrogenation unit successfully completed the intermediate handover of the project.

Huang Hesheng, general manager of Ningbo Jinfa, Xia Jianmeng, deputy general manager, as well as heads of construction unit Sinochem Sixth Construction, design unit Sinopec Ningbo Engineering Company, supervision unit Zhejiang Huajian and other units attended the ceremony.

Donghua Energy: Successful trial production of 400,000 tons of PP and 600,000 tons of PDH

On September 27, Donghua Energy announced that the first phase (I) of the Donghua Energy (Maoming) Propane Resources Comprehensive Utilization Project includes a set of propane dehydrogenation units with a design capacity of 600,000 tons/year, and a set of 400,000 tons/year propane dehydrogenation unit. Ton/year polypropylene equipment, public works and supporting facilities obtained trial production (use) registration for hazardous chemicals construction projects on September 15, 2023. Qualified polypropylene products have been produced and the equipment is operating smoothly.

Jinneng Chemical: The world’s largest PDH manufacturing base will be built by the end of the year

Jinneng Chemical: The world’s largest PDH manufacturing base will be built by the end of the year

Qingdao West Coast News

According to reports on September 4, at the construction site of the second phase of the Jinneng New Materials and Hydrogen Energy Comprehensive Utilization Project in Dongjiakou Economic Zone, Qingdao, there are towering chemical equipment and criss-crossing pipelines. Workers are busy nervously and orderly, and there is a lively atmosphere. Construction scene. After the second phase of the project is completed and put into operation, it will become the world’s largest propane dehydrogenation manufacturing base.

As a provincial and municipal key project and the first batch of major projects in the province to convert old and new kinetic energy, the Jinneng New Materials and Hydrogen Energy Comprehensive Utilization Project is invested and constructed by Jinneng Chemical Qingdao Company with a total investment of more than 50 billion yuan and an annual production capacity of 1.8 million tons. . The first phase of the project has been put into production in September 2021; the second phase will start in February 2022 and is planned to be completed and put into production by the end of this year.

微信扫一扫打赏

微信扫一扫打赏