Overview[1][2]

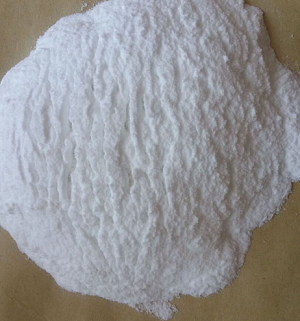

2-Nitro-4-methylsulfonylbenzoic acid is a white or light yellow crystalline powder at room temperature. It is an important intermediate in the synthesis of mesotrione, an excellent herbicide that has been widely used around the world. In addition, 2-nitro-4-methylsulfonyl benzoic acid is also widely used in dyes, pharmaceuticals and other industries, and its synthesis has received widespread attention.

Preparation[1-2]

Report 1. The industrial production method of high-purity 2-nitro-4-methylsulfonylbenzoic acid includes the following steps:

a. Generate crude product: oxidize o-nitromethylsulfone toluene with nitric acid to generate crude 2-nitro-4-methylsulfonylbenzoic acid with a mass content of 50 to 99%;

b. Neutralization: Put crude 2-nitro-4-methylsulfonyl benzoic acid and water into the neutralization kettle, and then add alkaline substances for neutralization, in which 2-nitro-4-methylsulfonyl The addition ratio of crude benzoic acid, water and alkaline substances is based on the mass ratio: crude 2-nitro-4-methylsulfonyl benzoic acid: water: alkaline substance = 1: (1 ~ 10): (0.25 ~ 3) , the pH value is controlled at 8 to 12 at the end of the neutralization reaction;

c. Reduction: Add a reducing agent with a mass of 0.01% to 10% of the total mass of the material to the material obtained in step b to perform a reduction reaction;

d. Mother liquor separation: Send the material obtained in step c to the first centrifuge for centrifugal filtration and separation to obtain the mother liquor; the filtered solid is 2-nitro-4-methylsulfonylbenzoic acid synthesis raw material 2-nitro- 4-methylsulfonyltoluene can be reused after washing with water.

e. Acid precipitation: Send the mother liquor obtained in step d into the acid precipitation kettle, add acid with a mass of 1% to 30% of the total mass of the mother liquor, and perform acid precipitation. At the end of the acid precipitation, the pH value is controlled at 0.1 to 1 ;

f. Separation of finished products: Send the material obtained in step e into the second centrifuge, and obtain the solid product 2-nitro-4-methylsulfonyl benzoic acid wet product after centrifugal filtration and separation;

g. Drying: The wet product of 2-nitro-4-methylsulfonyl benzoic acid is sent to the dryer to be dried, which is the final qualified product.

Report 2: Add 21.5g 2-nitro-4-methylsulfonyltoluene, 200g glacial acetic acid, 1.5g N-hydroxyphthalimide, and 0.5g fuming nitric acid into a 500mL autoclave. Air was introduced until the pressure in the kettle was 1.0MPa, stirring and heating were started, the reaction temperature was controlled at 110°C, and the reaction was carried out for 8 hours. After the reaction was completed, it was cooled to room temperature, the solution was filtered, and the filter cake was washed with 150 mL of clean water. Then the filter cake was dissolved with 0.1 M sodium hydroxide, and the insoluble matter was filtered off. The resulting filtrate was acidified with hydrochloric acid and dried to obtain 11.9 g of a light yellow solid. The melting point is 213.3~214.7°C. After high-performance liquid phase analysis, the purity of 2-nitro-4-methylsulfonyl benzoic acid is 98.8%, and the yield is 48%.

Apply[3]

CN201910612878.3 discloses a synthesis process of mesotrione. Mesotrione is also known as mesotrione and mesotrione. Its chemical name is 2-(4-methylsulfonyl 2-nitro- Benzoyl)-cyclohexane-1,3-dione, developed and produced by Syngenta, was sold in Europe under the trade name callisto in 2001. Mesotrione can inhibit p-hydroxyphenylpyruvate dioxygenase (HPPD), ultimately affecting carotenoid biosynthesis. It includes the following steps: (1) catalytic oxidation, using 2-nitro-4-methylsulfonyltoluene as the raw material, oxygen as the oxidant, and catalyzing the manganese oxide octahedral molecular sieve loaded heteropoly acid-transition metal salt to generate 2-nitro-4-methylsulfonyltoluene. methyl-4-methylsulfonyl benzoic acid; (2) acyl chlorination, acyl chlorination of 2-nitro-4-methylsulfonyl benzoic acid to generate 2-nitro-4-methylsulfonyl benzoyl chloride; (3) condensation, The condensation reaction of 2-nitro-4-methylsulfonyl benzoyl chloride and 1,3-cyclohexanedione produces an enol ester intermediate reaction liquid; (4) Rearrangement, the enol ester intermediate is catalyzed by a rearrangement catalyst Rearrange the enol ester to obtain a crude reaction liquid; (5) purify the crude reaction liquid to obtain the finished product of mesotrione. The invention optimizes the reaction conditions, has high conversion rate in each step, high yield and purity of the product, does not involve highly toxic materials in the whole production process, and has high safety.

Main reference materials

[1][China invention, China invention authorization] CN201510165545.2 Industrial production method of high-purity 2-nitro-4-methylsulfonylbenzoic acid

[2][Chinese invention] CN201810113992.7 Preparation method of 2-nitro-4-methylsulfonylbenzoic acid

[3] CN201910612878.3 A synthesis process of mesotrione

微信扫一扫打赏

微信扫一扫打赏