Background and overview[1][2]

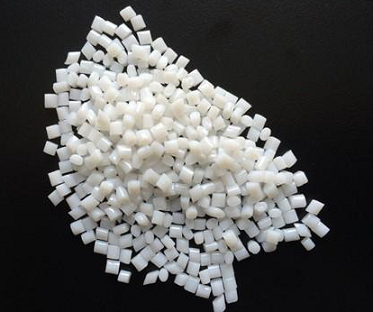

A polyester resin, also called PBT. Relative density 1.2~1.31. Low hygroscopicity. Excellent chemical resistance. Swell in dichloroethane. Decomposes in concentrated nitric acid and sulfuric acid. It has high heat distortion temperature and can be used for a long time at 150℃. Impact resistance, friction resistance and dimensional stability are all good. Used for gears, bearings, impellers, propellers, etc. that require lubricity and corrosion resistance. It is produced by polycondensation of dimethyl terephthalate and 1,4-butanediol. It is a crystalline thermoplastic polyester, tasteless, odorless, and non-toxic, with a melting point of 225°C, a relative density of 1.31, and a glass transition temperature of 27°C. It has excellent molding processability, resistance to oil and general organic solvents, excellent electrical properties, volume resistivity of 1016Ω·m, high heat resistance, and the long-term use temperature can exceed 120°C.

The preparation methods of PBT include: transesterification method using dimethyl terephthalate and 1,4-butanediol as raw materials; using high-purity terephthalic acid Direct esterification method with 1,4-butanediol as raw material. The former is generally used in industry. First, the transesterification reaction is carried out in a transesterification reactor under normal pressure and 160-190°C, and then the pressure is increased and the temperature is raised to perform the polycondensation reaction. The continuous process can be used to produce products with low, medium and high viscosities.

PBT resin is widely used as structural parts in the automotive, electronics, electrical, machinery, instrumentation and other industries. PBT reinforced with glass fiber and added with flame retardants is widely used in TV flame retardant parts, such as the skeleton of output transformers, bases, connectors and switches of various electrical appliances. PBT can be blended with other polymers to make plastic alloys. Its largest market is the automotive industry, such as making bumpers and igniters for cars. This alloy is also gradually used in the food industry, such as making microwave heating containers. , can withstand high temperatures above 160°C.

Modification[3][6]

With the increasing depletion of petroleum resources and the continuous expansion of downstream application fields such as the automobile industry, PBT engineering plastics have entered a new stage of rapid development, and my country has gradually become a country with a growing demand for PBT. One of the fastest countries. Modified PBT is widely used in various industries. Data shows that from 2009 to 2015, my country’s modified PBT imports increased from 10% to 35%. PBT engineering plastics modified by filling, blending and nanocomposite can improve its stiffness, toughness, impact resistance, heat resistance, flame retardancy, and reduce warpage, making it fully suitable for electronics, automobiles, fiber , biomedical and other fields have strict requirements on material performance.

CN201410176542.4 discloses a modified polybutylene terephthalate, which is made of polybutylene terephthalate plastic and additives. Additives include anti-interference agents, flame retardants, antioxidants, fillers and coupling agents. The anti-interference agents are cuprous sulfide conductive polyacrylonitrile fibers. The flame retardants are tris(2,3-dichlorophosphate). propyl) ester, the antioxidant is alkylphenol sulfide, the filler is silicon carbide, and the coupling agent is ethylenediaminepropyltriethoxysilane. The modified polybutylene terephthalate of the present invention adds a variety of additives to the polybutylene terephthalate plastic, so that the prepared modified polybutylene terephthalate has good quality and has It has the characteristics of high hardness and strength, good anti-electromagnetic interference and anti-static properties, good flame retardancy, good anti-aging properties, and low production cost.

Application[4-5]

CN201610971556.4 discloses a thermally conductive flame-retardant polybutylene terephthalate and a preparation method thereof. In parts by weight, the thermally conductive flame-retardant polybutylene terephthalate is Butylene dicarboxylate is composed of 75 to 80 parts of polybutylene terephthalate, 15 to 20 parts of thermal conductive flame retardant, 3 to 5 parts of compatibilizer and 0.3 to 0.5 parts of antioxidant. , the preparation method is to mix each component evenly, and then perform extrusion, traction, and granulation at 240°C to 260°C to prepare thermally conductive and flame-retardant polybutylene terephthalate. Resorcinol bis(diphenyl phosphate) is oil-soluble, and the amphiphilic polyethylene glycol 6000 monostearate can be assembled and coated through van der Waals interaction forces under shear conditions, while polyethylene glycol 6000 monostearate can be assembled and coated under shear conditions. The coordination bonds and terminal hydroxyl groups on the main chain of ethylene glycol 6000 monostearate can be complexed with magnesium oxide to form a thermal conductive flame retardant, giving polybutylene terephthalate good thermal conductivity and flame retardancy. performance.

CN201510197952.1 discloses a blended fiber of silk fibroin and polybutylene terephthalate. The glycol ester blend fiber includes the following components mixed in parts by mass: 1.0% to 5.0% silk fibroin nanopowder and 95.0% to 99.0% polybutylene terephthalate. The invention also discloses a method for preparing blended fibers of silk fibroin and polybutylene terephthalate. Silk fibroin is introduced into the blended fiber of silk fibroin and polybutylene terephthalate prepared by the invention. The wicking height changes significantly with time and has strong hygroscopicity. Using the silk fibroin provided by the invention Co-existence with polybutylene terephthalateClothes made of silk fiber have strong moisture absorption and perspiration properties and are more comfortable to wear; silk fibroin is rich in 18 kinds of amino acids, which is friendly to the human body and beneficial to human health.

Main reference materials

[1] Concise Dictionary of Fine Chemicals

[2]Fine Chemical Dictionary

[3] Bai Zhenhui, Su Tingting, Li Ping, Wang Zhanyong. Research progress on modification of polybutylene terephthalate [J]. New Chemical Materials, 2018, 46( 09):41-44.

[4] CN201610971556.4 Thermal conductive flame-retardant polybutylene terephthalate and its preparation method

[5]CN201510197952.1 A blended fiber of silk fibroin and polybutylene terephthalate and its preparation method

[6]CN201410176542.4 A modified polybutylene terephthalate

微信扫一扫打赏

微信扫一扫打赏