Toray Industries, Inc. recently announced its partnership with Honda Motor Co., Ltd.

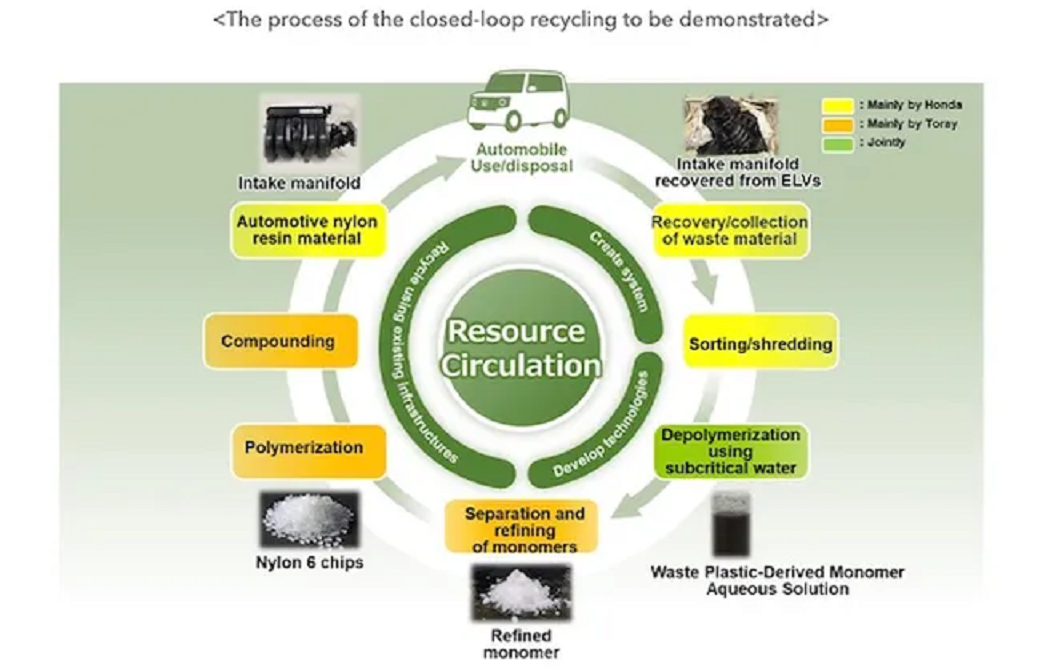

Signed an agreement to jointly develop chemical recycling technology for the recovery of glass fiber reinforced nylon 6 parts from end-of-life vehicles. The companies have begun validating the technology, which requires depolymerization with subcritical water and regeneration of the material into caprolactam, a virgin monomer.

Taking into account the characteristics of subcritical water such as its high permeability, solubility and hydrolysis of resin, the two companies have developed a technology that successfully uses this water to depolymerize nylon 6. Subcritical water refers to water under high temperature and pressure. It does not contain catalysts, additives have no effect on it, and can depolymerize nylon 6 within tens of minutes, thereby producing high yields of raw material monomers. Isolating, refining and repolymerizing this monomer makes it possible to regenerate nylon 6, which performs just like the original material.

The joint demonstration project was certified by Japan’s Ministry of the Environment (MOE) as part of its project to establish a decarbonized circular economy system. Toray and Honda Motor hope to use the project to establish a pilot facility capable of processing 500 tons of raw resin per year and conduct verification testing.

The promulgation of the “Plastic Resource Recycling Law” proves that in recent years, Japanese society has a growing demand for the recycling of beverage containers and clothing, as well as waste plastics. However, so far, due to the technical difficulties of classification, collection and recycling, the processing of automotive nylon resin waste has been limited to the recovery and utilization of heat energy generated during the incineration process.

The first step in this effort is to recycle used automotive plastic parts into identical automotive materials. The two companies will verify the depolymerized monomer separation and purification technology through the recovery of the intake manifold. They hope to apply these technologies to the recycling of chemicals from automotive resin parts around 2027.

In the future, the companies hope to expand the scope of the chemical recycling technology to clothing, films and other non-automotive applications. They also plan to invite other companies to participate and establish a chemical recycling program for nylon 6 in Japan. This effort will help achieve a circular economy and reduce greenhouse gas emissions.

One of Toray’s 2050 Sustainability Vision is to contribute to a world where resources are sustainably managed. Toray will continue to focus on R&D and contribute to a sustainable circular economy, thereby realizing its corporate philosophy of promoting social progress by providing new value while achieving sustainable growth.

微信扫一扫打赏

微信扫一扫打赏