Background and overview[1-3]

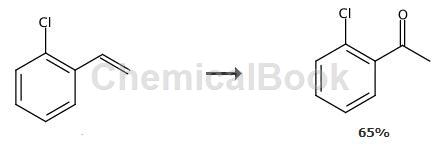

O-chloroacetophenone is a pharmaceutical chemical raw material used in the preparation of chlorbendarol and other drugs. Can be prepared from o-chlorostyrene.

Preparation[1]

In a 50mL reactor, add 1mmol o-chlorostyrene, 0.1mmol palladium/carbon and 5mL ethanol, stir and raise the temperature to 35°C, add 0.02mmol and mass fraction of nitric acid in sequence 6 mmol of 30% hydrogen peroxide was heated to 65°C and reacted for 6 hours. TLC (V ethyl acetate: V petroleum ether = 1:20) monitored the reaction progress. After the reaction is completed, the solid-liquid separation is performed to obtain the supported palladium catalyst and reaction liquid.

The obtained supported palladium catalyst was washed with 70% ethanol aqueous solution and reduced with a reducing agent, and then dried to constant weight. The reducing agent was formaldehyde.

Extract the reaction solution with ethyl acetate until the aqueous phase has no fluorescence, and obtain the organic phase. The organic phase is washed with water (3×30mL), dried over anhydrous sodium sulfate, and filtered with suction. , the crude product was obtained after distillation under reduced pressure. Use a mixed organic solvent of ethyl acetate:petroleum ether =1:20 as the eluent, and purify with a silica gel column to obtain the target product o-chloroacetophenone with a yield of 65%.

Application[2-3]

CN200910129336 discloses a preparation method of chlorbendanol and its salt. Clofedanol, whose English name is Clofedanol, is also known as clofedanol, clofedanol, and clofedanol. Chlopedianol or DETIGON, developed by the company, is an antitussive drug. In addition to its central antitussive effect, this drug also has antihistamine and atropine-like effects, and it can reduce bronchospasm and mucosal congestion edema. It is suitable for treating dry cough or cough caused by acute respiratory infection, and is often used in combination with expectorants. The preparation method includes the following steps: under an acidic catalyst, o-chloroacetophenone, paraformaldehyde, and dimethylamine hydrochloride are subjected to Mannich reaction in an organic solvent to prepare 1-o-chlorophenyl-3 -Dimethylamino-1-propanone hydrochloride; neutralize the obtained 1-o-chlorophenyl-3-dimethylamino-1-propanone hydrochloride with a base to obtain 1-o-chlorophenyl -3-Dimethylamino-1-propanone; perform an addition reaction between the obtained 1-o-chlorophenyl-3-dimethylamino-1-propanone and phenyllithium in an organic solvent to prepare chlorbendarol ; and reacting the prepared chlorbendanol with hydrochloric acid to prepare lorbendanol hydrochloride. The above preparation method is simple to operate, easy to control, has high safety performance, and can be used for industrial production.

CN201210215170.2 discloses a synthesis method of 2-(2-(4-chlorophenyl)phenyl)acetic acid. Based on the existing technology, o-chlorobenzene is used. Using ethanol as raw material, multiple routes were tried while optimizing the synthesis route, and the key intermediate for the synthesis of arsenaline, 2-(2-(4-chlorophenyl)phenyl)acetic acid, was obtained. 2-(2-(4-Chlorophenyl)phenyl)acetic acid is an important intermediate raw material for the synthesis of arsenal. The present invention mainly improves the synthesis route of 2-(2-(4-chlorophenyl)phenyl)acetic acid, reduces the harshness of reaction conditions, and at the same time improves the production efficiency of 2-(2-(4-chlorophenyl)phenyl)acetic acid. base) yield of acetic acid. The synthetic method of 2-(2-(4-chlorophenyl)phenyl)acetic acid is prepared by adding 500 grams of o-chloroacetophenone, 1000 grams of p-chlorophenol, and 250 grams of hydroxide into a 3000 ml three-necked bottle. Sodium, 40 grams of copper powder, stir magnetically under nitrogen protection, heat and stir for 10 hours, cool to room temperature, pour the mixture into 2000 ml of 3N sodium hydroxide solution, a mixed solution of ethyl acetate and petroleum ether (ethyl acetate (20% ester) to obtain the crude product of 1-(2-(4-chlorophenoxy)phenyl)ethanone, which was spin-dried to obtain the crude product of 1-(2-(4-chlorophenoxy)phenyl)ethanone. Crude product, no purification required. The obtained crude 1-(2-(4-chlorophenoxy)phenyl)ethanone, 250 g of sublimated sulfur powder and 1000 g of morpholine were heated and refluxed for 5 hours, and then cooled to room temperature. Add the cooled mixture to a mixed solution containing 1800 ml of concentrated hydrochloric acid and 1800 ml of glacial acetic acid, stir mechanically, heat and reflux for 18 hours, then rotary evaporate under reduced pressure to about 60% of the solution, and pour the residual liquid into 4000 ml of water, stir mechanically, if a solid precipitates, filter. Dissolve the obtained solid with 10,000 ml of ethyl acetate, add 2,000 ml of water and 500 g of sodium bicarbonate, stir for 10 minutes, and separate the liquids. Spin the organic phase to dryness to obtain a black solid. Dissolve the obtained black solid into 5000 ml of 3N sodium hydroxide solution. Use a mixed solution of ethyl acetate and petroleum ether (ethyl acetate 15%) to extract the impurities. Use concentrated hydrochloric acid for the aqueous phase. Adjust the acidity to about 3, and a brown solid will precipitate. Boil the brown solid with 3500 ml of a mixed solution of petroleum ether and toluene (toluene 10%) for 2 hours, cool to room temperature, and filter to obtain 431 grams of yellow-brown solid, which is 2‑( Pure form of 2-(4-chlorophenyl)phenyl)acetic acid.

Main reference materials

[1] [Chinese invention] CN201811307422.8 A method for preparing methyl ketone by palladium-catalyzed oxidation of olefin compounds

[2] CN200910129336.7 Preparation method of chlorbendarol and its hydrochloride

[3] CN201210215170.2 A kind of 2-(2-(Synthesis method of 4-chlorophenyl)phenyl)acetic acid

微信扫一扫打赏

微信扫一扫打赏