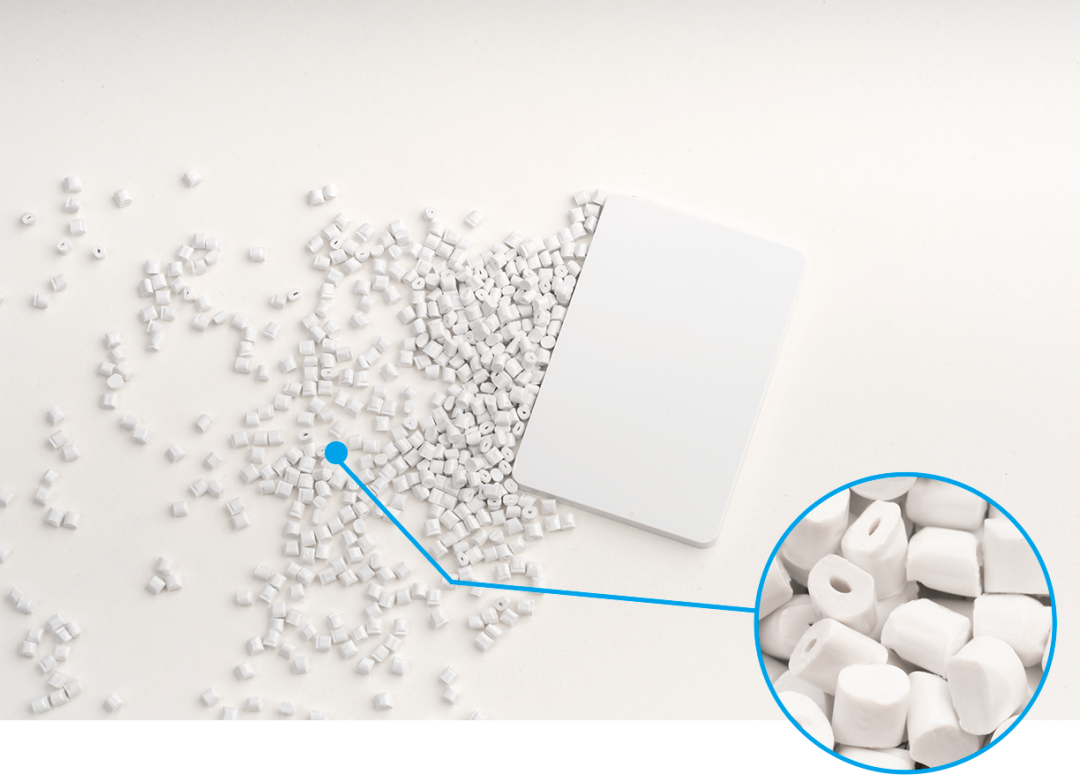

On April 19, announced the launch of post-consumer recycled (PCR) polycarbonate with a recycling content of 90%, which can be used in consumer electronics and other fields. Makrolon® polycarbonate reduces carbon emissions by 70% compared to virgin fossil-based products. will first sell this brand in the Asia-Pacific region.

The 90% post-consumer recycled polycarbonate launched this time has outstanding color matching capabilities and can achieve high-saturation colors and whiteness that are difficult to achieve with traditional high-content recycled plastics. The key to achieving this breakthrough lies in carefully selecting high-quality raw materials and optimizing the material formula during the blending production process. This product uses environmentally friendly halogen-free flame retardants and complies with UL

94 V-0 flame retardant standard, which meets performance requirements without causing additional impact on the environment.

In order to meet the market demand for this type of more sustainable polycarbonate, is building the company’s first production line in the world dedicated to the production of physically recycled polycarbonate at its Shanghai integrated base. The production line is expected to be put into operation within the year. More than 25,000 tons of high-quality polycarbonate with physically recycled content can be produced annually.

By mass balance method

Achieve zero carbon footprint

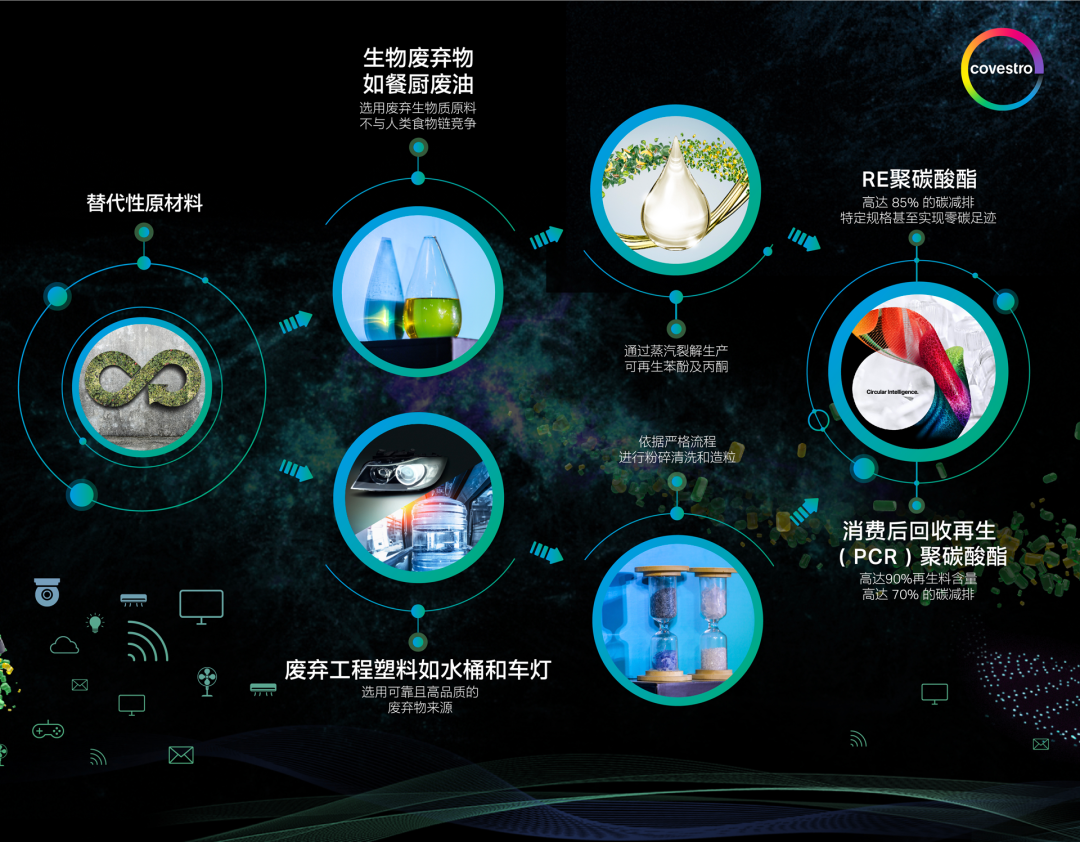

In addition to post-consumer recycled products through physical recycling, is also continuing to develop polycarbonates with a share of recycled biomass feedstock based on a mass balance approach. ’s mass-balanced products have been internationally recognized by the ISCC

PLUS standard certification.

As the latest development, the company can now regularly supply Makrolon® RE polycarbonate with a sustainable share of up to 89%. Some of these products, including zero-carbon footprint polycarbonate, are produced with 100% renewable electricity (based on a TüV-certified system). As early as the end of 2021, began supplying the world’s first zero-carbon footprint polycarbonate in Europe.

Mass Balanced Polycarbonate delivers the same high quality and performance as fossil-based products. Customers can use this low carbon footprint solution immediately without changing their process flow.

In order to make it easier to understand, the editor will show you a picture to understand how PCR polycarbonate and RE polycarbonate are formed 👇👇

CQ

The newly launched PCR polycarbonates with 90% recycled content and the RE series polycarbonates based on mass balance methods are members of ’s family of CQ recycling solutions. launched a new CQ brand concept in May 2022. CQ (Circular

Intelligence) stands for Circular Intelligence and is designed for products containing at least 25% alternative raw materials to help customers find circular solutions more easily.

微信扫一扫打赏

微信扫一扫打赏