Background and overview[1]

Methyl 5-hydroxy-2-methylbenzoate is an important and commonly used pharmaceutical intermediate. For the preparation of methyl 5-hydroxy-2-methylbenzoate, there are literature reports using 5-amino-2 -Methyl benzoic acid is used as the raw material, and the target product is obtained through diazotization, hydrolysis, and re-esterification, and finally the target compound is obtained through column purification; or 5-amino-2-methylbenzoic acid methyl ester is used as the raw material, and the target product is obtained through diazotization. ionization, hydrolysis, and finally column purification.

The main drawback of these processes is that they require column purification and are not suitable for large-scale production. Therefore, finding a suitable post-processing method so that the process can be applied to large-scale production has become a key issue that needs to be solved.

Preparation [1]

A method for effectively preparing and purifying 5-hydroxy-2-methylbenzoic acid methyl ester, which mainly solves the technical problem that the existing synthesis and purification process is not easy to amplify and requires column purification. This method has the characteristics of short reaction time and simple purification process, and is suitable for large-scale industrial production; the post-treatment process of the reaction has been greatly improved, and the by-product 5-hydroxy-2-methylbenzoic acid is removed by washing with water, and then used The mixed solvent of methyl chloride and n-heptane is used for recrystallization, which not only improves the purity of the product, but also ensures the yield.

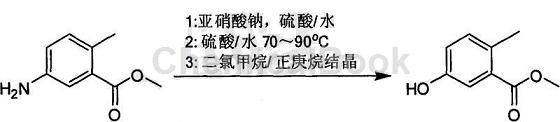

Includes the following steps: using 5-amino-2-methylbenzoic acid methyl ester as raw material, sequentially undergoing diazotization and hydrolysis reactions to obtain a crude product. After the crude product is dissolved in dichloromethane, the by-products generated in the reaction solution are removed by washing with water. 5-Hydroxy-2-methylbenzoic acid, the obtained crude product 5-hydroxy-2-methylbenzoic acid methyl ester is then recrystallized with a mixed solvent of dichloromethane and n-heptane to obtain 5-hydroxy-2-methyl as a light yellow powder. Methyl benzoate. The number of water washings to remove the by-product 5-hydroxy-2-methylbenzoic acid generated in the reaction solution is 2 to 3 times, and the volume of the mixed solvent used for crystallization is 4 times the feed volume of the raw material 5-amino-2-methylbenzoic acid methyl ester. ~8 times, add methylene chloride and n-heptane in the mixed solvent at a volume ratio of 1:2. The specific synthesis process route is as follows:

The diazotization and hydrolysis reaction steps are: 5-amino-2-methylbenzoic acid methyl ester is dissolved in a sulfuric acid solution, sodium nitrite solution is added dropwise at 0 to 5°C, and the reaction is carried out at 0 to 5°C After 1 hour, the obtained diazonium salt solution was dropped into the sulfuric acid solution for hydrolysis. The hydrolysis temperature of the diazonium salt was 70-90°C, and the hydrolysis time was 30-60 minutes. After the reaction was completed, the temperature was lowered and crystallized, and the solid was filtered to obtain a crude product.

Main reference materials

[1] CN201010125439.9 Synthesis method of high-purity 5-hydroxy-2-methylbenzoic acid methyl ester

微信扫一扫打赏

微信扫一扫打赏