Background [1][2]

2-Benzoylacetanilide is a very widely used acylating agent for organic synthesis. It can also be used as an intermediate and analytical reagent for pesticides. Although benzoylacetanilide has applications, there are few details about benzoylacetanilide. There are very few domestic literature reports on synthesis, so studying the preparation method of benzoyl acetanilide has important industrial application value.

If 2-benzoacetanilide is inhaled, please move the patient to fresh air; if there is skin contact, take off contaminated clothing, rinse the skin thoroughly with soap and water, and seek medical treatment if you feel unwell; if In case of eye contact, separate eyelids, rinse with running water or saline, and seek medical attention immediately; if ingested, rinse mouth immediately, do not induce vomiting, and seek medical attention immediately. Advice to protect rescuers is as follows: Move the patient to a safe place, consult a doctor, and if conditions permit, please show this chemical safety data sheet to the doctor who comes to the scene.

In case of leakage, if there is a small leakage, collect the leaked liquid in a sealable container as much as possible, absorb it with sand, activated carbon or other inert materials, and transfer it to a safe place. It is prohibited to flush it into the sewer; if there is a large leakage, build a dike Or dig a pit to contain it, seal the drainage pipe, cover it with foam to inhibit evaporation, use an explosion-proof pump to transfer it to a tanker or a special collector, and recycle or transport it to a waste treatment site for disposal.

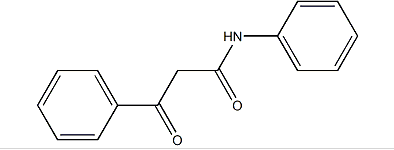

Structure

Synthetic route [1][2]

Method 1: Use ethyl benzoacetate and aniline as raw materials, react in anhydrous xylene at 120°C with stirring, then distill the reactant system under reduced pressure, recover ethanol, and obtain crude [ 1]. 2-Benzoylacetanilide can be obtained by recrystallization and purification in benzene, chloroform or ethanol.

Method 2: A method for preparing the organic intermediate benzoyl acetanilide. The organic intermediate uses ethyl benzoyl acetate and aniline as raw materials, and reacts to synthesize benzoyl in the presence of a catalyst and a solvent. For acylacetanilide, filter it after the reaction is completed. The filtered organic phase is cooled to 8-10°C, the crystallization is complete, and it is centrifuged and filtered to obtain the benzoacetanilide product. Among them, the dosage ratio of ethyl benzoacetate, aniline, catalyst and solvent is calculated by mass: ethyl benzoacetate:aniline:catalyst:solvent=1:0.53~1.22:0.016~0.078:1.56~3.12.

The catalyst is sodium methoxide or sodium ethoxide, preferably sodium ethoxide; the solvent is petroleum ether or n-heptane or n-hexane, preferably petroleum ether; the reaction temperature is 120-130°C, and the reaction time is 6-12h. Compared with the existing technology, it has the following advantages: the present invention uses ethyl benzoacetate and aniline as raw materials to synthesize benzoyl acetanilide. The separation and purification process is simple, the reaction time is short, and the yield of the product can reach more than 94%. It has high purity, low energy consumption, little environmental pollution and low cost. It is an ideal process for industrialized production.

The specific steps are as follows: In a 250mL four-necked flask equipped with a thermometer, add 40g of petroleum ether, 19.2g of ethyl benzoyl acetate, 11.2g of aniline, and 0.5g of catalyst, install the condenser tube, and start the stirrer. When the temperature is raised to 120-130°C, the generated ethanol is continuously evaporated during the reaction, and the reaction time is 6-12 hours. After the reaction is completed, filter the product. The filtered organic phase is cooled to 8-10°C, crystallized completely, and centrifuged to obtain the benzoyl acetanilide product. The product yield is 94.92% and the melting point is 107-108°C.

Method 3: In a 250mL four-necked flask equipped with a thermometer, add 40g petroleum ether, 19.2g ethyl benzoyl acetate, 14g aniline, and 0.5g catalyst, install the condenser tube, start the stirrer, and heat to At 120-130°C, the generated ethanol is continuously evaporated during the reaction, and the reaction time is 6-12 hours. After the reaction is completed, filter, cool the filtered organic phase to 8-10°C, crystallize completely, and centrifuge to obtain the benzoyl acetanilide product. The product yield is 95.28% and the melting point is 107-108°C.

Method 4: In a 250mL four-necked flask equipped with a thermometer, add 30g petroleum ether, 19.2g ethyl benzoyl acetate, 14g aniline, and 0.7g catalyst, install the condenser tube, start the stirrer, and heat to At 120-130°C, the generated ethanol is continuously evaporated during the reaction, and the reaction time is 6-12 hours. After the reaction is completed, filter, cool the filtered organic phase to 8-10°C, crystallize completely, and centrifuge to obtain the benzoyl acetanilide product. The product yield is 95.64% and the melting point is 107-108°C.

Method 5: In a 250mL four-necked flask equipped with a thermometer, add 40g petroleum ether, 19.2g ethyl benzoyl acetate, 14g aniline, and 1.5g catalyst, install the condenser tube, start the stirrer, and heat to At 120-130°C, the generated ethanol is continuously evaporated during the reaction, and the reaction time is 6-12 hours. After the reaction is completed, filter, cool the filtered organic phase to 8-10°C, crystallize completely, and centrifuge to obtain the benzoyl acetanilide product. The product yield is 95.91% and the melting point is 107-108°C.

Method 6: In a 250mL four-necked flask equipped with a thermometer, add 60g of petroleum ether, 19.2g of ethyl benzoyl acetate, 14g of aniline, and 0.8g of catalyst, install the condenser tube, start the stirrer, and heat to At 120-130°C, the generated ethanol is continuously evaporated during the reaction, and the reaction time is 6-12 hours. After the reaction is completed, filter the filtered organic phase, cool it to 8-10°C, crystallize completely, and centrifuge to obtain the benzoyl acetanilide product.The product yield is 94.06%, and the melting point is 107-108°C.

Purpose[1][3]

2-Benzoylacetanilide is a very widely used organic synthesis acylating agent. It can also be used as a pesticide intermediate and analytical reagent. Examples of its application are as follows: used to synthesize a pyrazolo[3,4-b]pyrrolo[3,4-d]pyridine derivative. Pyrazolo[3,4-b]pyrrolo[3,4-d]pyridine derivatives are a new type of heterocyclic compound formed by the fusion of three heterocyclic rings: pyrazole, pyrrole and pyridine. This heterocyclic compound has been found to be Compounds with cyclic skeletons have good pharmacological activity and can be used to treat anxiety disorders caused by neuronal inhibition caused by γ-aminobutyric acid.

This synthesis method utilizes a multi-component reaction, using substituted benzoylformaldehyde, substituted benzoylacetanilide and substituted 5-aminopyrazole as raw materials, and undergoes a three-component reaction under microwave radiation conditions to obtain the target in one step. Compounds, namely pyrazolo[3,4-b]pyrrolo[3,4-d]pyridine derivatives. The advantage of this method is that the synthesis process of the present invention uses a multi-component reaction to construct a pyrrole ring and a pyridine ring in one step by using three raw materials through a “one-pot cooking” method. Since the separation and purification of intermediates are omitted in the synthesis process Operation is an efficient and green synthesis method. This method has wide adaptability, and raw materials with various substituents can be adapted to this reaction. It provides a simple and effective method for synthesizing compounds of this type of structure.

Main reference materials

[1] Practical Fine Chemical Dictionary

[2] CN201410077199.8. Preparation method of organic intermediate benzoyl acetanilide

[3] CN201810124229.4. Pyrazolo[3,4-b]pyrrolo[3,4-d]pyridine derivative and its synthesis method

微信扫一扫打赏

微信扫一扫打赏