On October 2, Mitsubishi Chemical Group announced that its Yokkaichi plant will optimize its product portfolio and adopt plant-based PTMG (polytetramethylether glycol, hereinafter referred to as “BioPTMG”) in the fall of 2023. Dispense product jars. As a result, Mitsubishi Chemical Group will be able to steadily meet growing demand and will transport flagship BioPTMG in tank trucks and ISO storage tanks in addition to traditional oil tanks and drums.

1000 and BioPTMG 2000 products.

In addition, in order to meet further growth in future demand, Mitsubishi Chemical Group plans to increase production capacity to 3,000 tons/year.

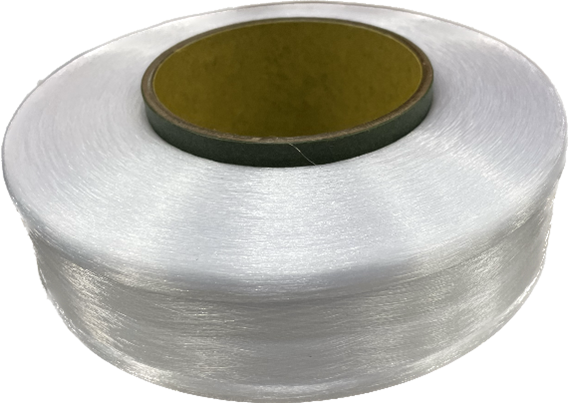

BioPTMG is a plant-based alcohol developed by Mitsubishi Chemical Group in 2021 to provide flexibility, durability and high elasticity to polyurethane and polyester products. Mitsubishi Chemical Group’s unique refining technology eliminates coloring from the resin, allowing it to be used in a wide range of applications, like petroleum-based products, from interior decoration and apparel to industrial materials. With a biobased content of over 92%, BioPTMG not only helps reduce the consumption of petroleum resources, but also reduces greenhouse gas emissions, as the plants used as base materials consume carbon dioxide during the growth stage. BioPTMG is expected to reduce greenhouse gas emissions by approximately 40% over its life cycle compared to petroleum-based products.

BioPTMG is used in Biomass Mobilon, a

Inc.) developed and sold in 2022 spandex (elastic fiber). This is the first time BioPTMG has been used in spandex, and it is also the largest application field of PTMG. It is expected to be more widely used in the future.

Mitsubishi Chemical Group will accelerate the research and development of BioPTMG and other plant materials to contribute to the realization of sustainable development.

微信扫一扫打赏

微信扫一扫打赏