Background and overview[1][2]

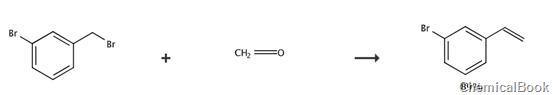

3-Bromostyrene, also called 1-bromo-3-vinylbenzene, is a pharmaceutical intermediate that can be prepared in one step from m-bromobenzyl bromide and paraformaldehyde.

Preparation[1-2]

Report 1,

Add 163.2mg K2CO3 (the molar ratio to m-bromobenzyl bromide is 1.5) into a Schlenk test tube equipped with a magnetic stirrer. :1), 314.4mg triphenylphosphine (molar ratio to m-bromobenzyl bromide is 1.5:1), 3.8mg Ru(bpy)3Cl2-6H2O (molar ratio to m-bromobenzyl bromide is 0.005:1), 60mg Paraformaldehyde, 10mL acetonitrile, 248mg 3-bromobenzyl bromide, argon gas for 5 minutes, under visible light, room temperature, reaction time is 4h, the product is separated and purified by petroleum ether, and the product is 162mg 3-bromostyrene. The yield is 89%.

3-bromostyrene: 1H NMR (CDCl3, 400MHz) δ7.56 (s, 1H), 7.53 (d, J = 8.24Hz, 2H), 7.39 (d, J=7.79Hz, 1H), 7.32 (d, J=7.79Hz, 1H), 7.20 (t, J=7.79Hz, 1H), 6.65 (dd, J1= 17.63Hz, J2= 10.99Hz,1H),5.76(d,J=17.40Hz,1H),5.30(d,J=10.99Hz,1H).13C NMR (CDCl3 , 100MHz)δ139.8,135.6,130.8,130.2,129.3,125.0,122.9,115.5.EI-MS:M+m/z 182.

Report 2,

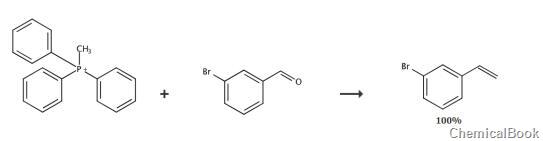

Dissolve 3-bromobenzaldehyde (10g, 54.05mmol) in 102mL dioxane and water (V/V=50:1) mixed solvent, add potassium carbonate (18.64g, 135mmol) and methyl trisulfide Phenylphosphonium iodide (43.70g, 108.11mmol) was heated to 100°C and stirred for 12 hours. Filtration, the filter cake was washed with 200 mL n-hexane and ethyl acetate (V/V=50:1) mixed solvent, the filtrate was concentrated under reduced pressure, and the resulting residue was purified by silica gel column chromatography to obtain the title product 3-bromostyrene (10g , yellow liquid), yield: 100.0%.

Apply[3]

CN201810108131 reports a flame-retardant polystyrene foamed wood-like material and a preparation method thereof. The material is made of the following raw materials in terms of mass percentage: flame-retardant copolymer polystyrene 30- 50%, small molecular weight polytetrafluoroethylene 20-45%, inorganic flame retardant filler 10-25%, foaming agent 1-3%; among them, flame retardant copolymer polystyrene is composed of vinyl diethyl phosphate, It is produced by copolymerizing 4-bromo-β,β-difluorostyrene, tribromoethylene, 3-bromostyrene and triphenylvinylsilane as raw material monomers. The polystyrene foam material provided by the invention has good mechanical properties and long-lasting flame retardant properties.

Main reference materials

[1] [Chinese invention] CN201710201407.4 A method of light-induced one-pot synthesis of olefin compounds

[2] [China invention, China invention authorization] CN201210300982.7 Benzodioxane derivatives, their preparation methods and their applications in medicine

[3] CN201810108131.X A kind of flame-retardant polystyrene foamed wood-like material and its preparation method

微信扫一扫打赏

微信扫一扫打赏