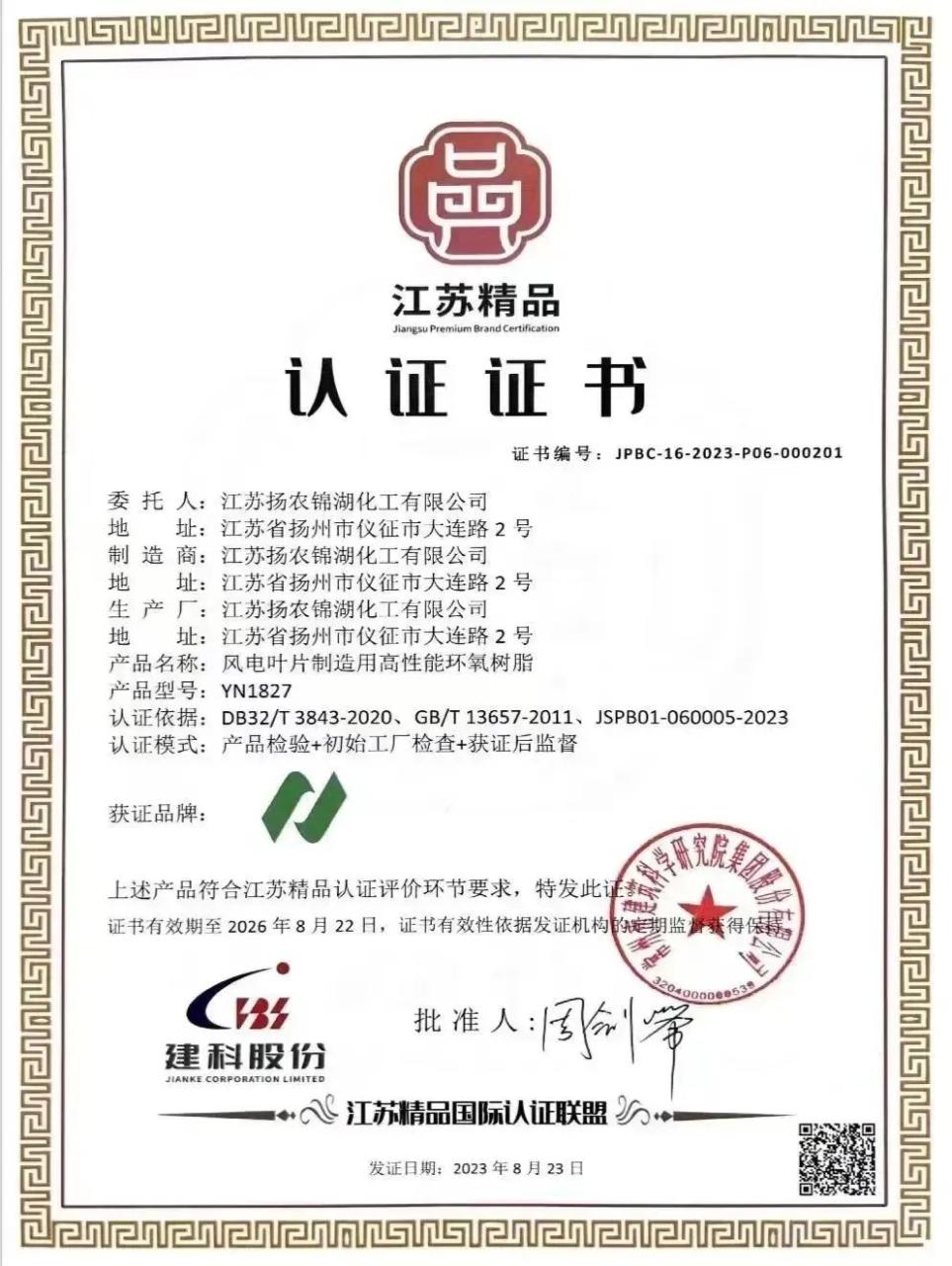

Recently, Yangnong Kumho Company’s “high-performance epoxy resin for wind turbine blade manufacturing” product successfully passed the “Jiangsu Premium” international certification alliance certification and was awarded the “Jiangsu Premium” certification.

“Jiangsu Premium” certification is a pioneering work for Jiangsu Province to refer to international practices and use market mechanisms to promote brand strategy under the new situation. Its main purpose is to use standards as a guide and certification as a means to meet high standards and meet high standards. Products and services with quality requirements are subject to third-party certification to promote the formation of a group of “Jiangsu quality” brand groups with independent innovation, high-end quality, excellent service, excellent reputation and market recognition.

With the vigorous development of the wind power industry, wind power blades have become one of the fastest-growing, most revolutionary and most successful products in global technology products and process materials in the past decade. Yangnong Kumho Company’s high-performance epoxy resin products for wind turbine blade manufacturing also emerged at the same time.

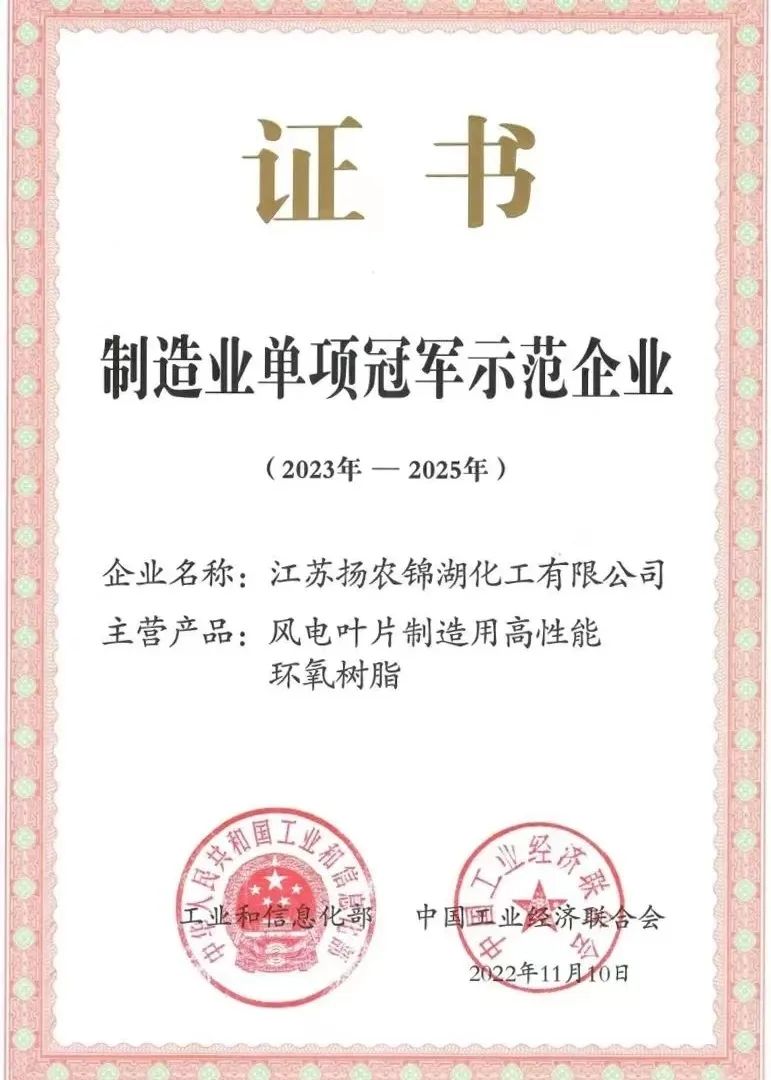

As one of the first domestic companies to research high-performance epoxy resin for wind turbine blade manufacturing, Yangnong Jinhu Company completed the introduction and development of high-performance epoxy resin technology for wind turbine blade manufacturing through international industry-university-research cooperation in 2012; in 2013, it became An epoxy resin manufacturer that has passed the wind power GL certification; in 2015, the wind power epoxy resin product YN1827 was certified as a “high-tech product” by Jiangsu Province; in 2016, it independently developed the “high-purity epoxy resin purification and separation process” and “epoxy resin segmentation” Reaction and closed-circuit cycle process” can meet the needs of wind turbine blade manufacturers for resins with different properties; in 2021, liquid epoxy resin YN1828 was recognized as a “Specialized New Product” in Jiangsu Province, and the company was selected as the No. 1 product announced by the Ministry of Industry and Information Technology Three batches of specialized and new “little giant” enterprises; in 2022, the company will become a “manufacturing individual champion demonstration enterprise” recognized by the Ministry of Industry and Information Technology and the China Federation of Industrial Economics.

Yangnong Kumho Company will rely on the integrated advantages of Sinochem’s epoxy resin industry chain, be market-oriented, adhere to the combination of product innovation and application innovation to break through key core technologies, accelerate the development of high value-added special resins and downstream applications, and strive to create The industrial development pattern with global competitive advantages has become a benchmark enterprise with scale, characteristics and core competitiveness in the epoxy resin industry.

微信扫一扫打赏

微信扫一扫打赏