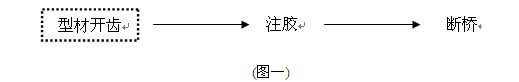

Aluminum profile glue injection technology (hereinafter referred to as glue injection technology ) is a technology that produces polyurethane-injected heat-insulating aluminum profiles (hereinafter referred to as glue-injected aluminum profiles) by injecting polyurethane material into the aluminum profile heat-insulating groove and breaking the bridge after the polyurethane material solidifies. The process diagram is as follows (for compatible Aluminum profiles with good properties can save the tooth opening step):

Glue injection technology was developed in the 1970s and 1980s Originated from the United States, it has been widely used in the North American market. This technology has been introduced to China for nearly ten years. In recent years, it has developed rapidly with the increase in glue injection equipment and polyurethane insulation glue supply channels.

This technology has the advantages of stable product quality and high production efficiency. The heat-insulating aluminum profiles produced with this technology have the characteristics of good water tightness, flexible cross-section design, saving the amount of aluminum profiles, etc. Therefore, this technology is becoming more and more popular in the domestic market. It is favored by more and more aluminum profile manufacturers. A large number of glue injection production lines have been put into use, and the glue injection aluminum profile market is showing rapid growth momentum.

While its market is booming, there are also many problems. Most of the new manufacturers investing in glue-injection aluminum profile production lines do not have any relevant production experience. After a short period of training, they can only reach the level where they can produce“ state, and rushed into mass production without fully understanding the technology. This lack of understanding leads to many quality problems in the production process. The existence of these problems not only affects the development of glue injection manufacturers, but also affects the development of the glue injection production industry.

Based on our understanding and experience of glue injection technology, here are some key points in the production process of glue injection aluminum profiles. We hope to be helpful to glue injection aluminum profile companies and thus play a role in promoting the development of the industry. Due to the author’s lack of knowledge and experience, this article may contain some fallacies, and I apologize for this.

1. Performance of polyurethane injection materials

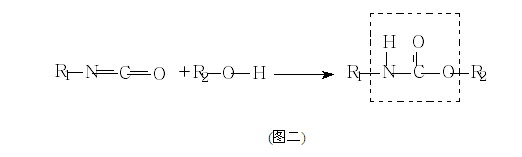

Polyurethane is the abbreviation of polyurethane, its English name is Polyurethane, and its abbreviation is PU (or PUR). Polyurethane is produced by the addition polymerization reaction of polyol and polyisocyanate. Its chemical reaction can be expressed by the following reaction formula:

Above The two-component polyurethane raw material is called polyurethane composite material or polyurethane original gum (hereinafter referred to as polyurethane original gum).

In order to ensure the performance of polyurethane injection materials, glue-injected aluminum profile manufacturers can monitor the performance of polyurethane injection materials from different levels, including: polyurethane raw rubber parameters, polyurethane material properties, and glue-injected aluminum profile properties.

1.1polyurethane original glue Performance parameters

There are many performance parameters that characterize polyurethane original gum. Among them, the more important performance parameters are listed below according to different original gum components.

Polyol components: viscosity, water content, reaction speed, etc.

Isocyanate components: viscosity, isocyanate content (NCO%), etc.

Generally speaking, polyurethaneinsulation glue manufacturers will generally provide inspection certificates (COA) for each batch of products when shipping. The insulation glue The user manufacturer can check and accept according to the standards of the thermal insulation glue manufacturer. If conditions permit, the user manufacturer can take samples and test by themselves. The prerequisite is that the monitoring method should be as consistent as possible with the insulation glue manufacturer.��Determine the compatibility of the coating manufacturer, model, batch) to treat aluminum profiles. If incompatibility occurs, it can be overcome by changing the paint (paint manufacturer, model, batch), reducing the amount of paint on the inner surface of the notch, opening teeth, etc.

4. Other factors

4.1The design of the glue injection slot

Some manufacturers do not use standard notches, resulting in problems such as too deep locking points, resulting in a reduction in the actual cross-sectional area of polyurethane insulation glue , thus causing a decrease in strength and even serious quality problems.

4.2aluminum profile section Design

For aluminum profiles with larger cross-sections, improper cross-section design may cause stress concentration, making the glue-injected aluminum profiles easy to break at the heat-insulating glue part, affecting their use.

4.3Broken Bridge Time

During the process of curing from liquid raw glue to solid polyurethane insulation glue, shrinkage may cause the notch of the aluminum profile to shrink or even open. The impact is particularly obvious for thinner aluminum profiles. Choose Proper bridge breaking time can minimize the deformation of the notch.

4.4Glue-injected aluminum profile Storage of finished products

On the market, it was found that the finished glue-injected aluminum profiles were deformed due to long-term storage in the open air and the inability to keep the layers stacked flat, which affected normal use. Proper storage of finished products is also essential.

In addition to these factors, many glue-injected aluminum profile manufacturers have not formed a systematic quality management system due to poor management. Different problems have occurred during the production process, and even unqualified aluminum profiles have been released to the market. When customers have quality complaints, it is impossible to trace back and find the reasons. This not only affects the development of the company itself, but also affects the development of the glue-injected aluminum profile market.

Summary:

Polyurethane insulation glue is a key raw material for glue-injected aluminum profiles, and its quality control is an important guarantee for the quality of glue-injected aluminum profiles. At the same time, because the heat-insulating glue raw material purchased by the glue-injected aluminum profile manufacturer is a two-component liquid original glue, the process of converting the original glue into heat-insulating glue occurs during the production process of glue-injected aluminum profiles. Therefore, the production of glue-injected aluminum profiles The control of the factory’s on-site process is also crucial. The composite of heat-insulating glue and aluminum profiles is through the bonding force between the heat-insulating glue and the surface of the aluminum profiles. The surface treatment method of the aluminum profiles has a decisive impact on the bonding force. Problems in any link may lead to quality problems of glue-injected aluminum profiles, and sufficient attention should be paid to them.

The full cooperation between polyurethane insulation glue manufacturers and glue-injected aluminum profile manufacturers can ensure the orderly production of glue-injected aluminum profiles. Among them, polyurethane insulation glue manufacturers not only need to provide stable and qualified insulation glue raw materials, but also should intervene in the production of glue-injected aluminum profiles as consultants for glue-injected aluminum profile manufacturers and provide training for glue-injected aluminum profile manufacturers. and guidance; while manufacturers of glue-injected aluminum profiles should do a good job in their own production management, they should also actively cooperate with polyurethane insulation glue manufacturers and communicate in a timely manner. Only through positive interaction between both parties can we grow together, provide the market with excellent products, and promote the development of the glue-injected aluminum profile market.

微信扫一扫打赏

微信扫一扫打赏