Potting glue, we are not unfamiliar with it, because we will use a variety of different glues in our lives or work. Potting glues can be used in the construction industry, but today we are going to talk about Potting glue for the electronics industry.

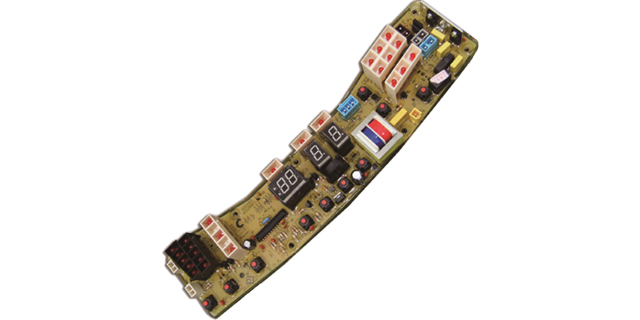

Potting is to pour the liquid polyurethane compound into the device equipped with electronic components and circuits mechanically or manually, and solidify it under normal temperature or heating conditions to become a thermosetting polymer insulation material with excellent performance.

Potting glue is also called electronic glue. Its main functions are bonding, sealing, potting, coating, etc. It thus protects electronic and electrical components from moisture, dust, corrosion, and shock, and improves performance and stability parameters. Moreover, it is liquid before vulcanization, making it easy to pour and use.

Now that you know the potting glue, what are the most commonly used potting glues in the electronic world?

Most of today’s electronic products are potted with silicone potting glue, polyurethane potting glue and epoxy. Potting glue. Because these three glues can be selected for different products. Its adhesion is very good and it is also very good in terms of sealing and waterproofing. The following is a detailed explanation of the differences between these three potting glues

1、Silicone potting glue

Long-term and effective protection of sensitive circuits and electronic components is undoubtedly essential for today’s sophisticated and Highly demanding electronic applications play an increasingly important role, and two-component silicone potting materials are undoubtedly one of the best choices. Silicone potting materials have stable dielectric insulation, which is an effective guarantee to prevent environmental pollution. At the same time, it can eliminate the stress caused by impact and vibration within a wide range of temperature and humidity.

2, Polyurethane potting glue

Polyurethane elastic potting material overcomes the shortcomings of brittleness of commonly used epoxy resin and low strength and poor adhesion of silicone resin. It has excellent water resistance. It has the characteristics of heat resistance, cold resistance, UV resistance, acid and alkali resistance, high and low temperature impact resistance, moisture resistance, environmental protection, and high cost performance. It is an ideal potting protection material for electronic components.

3, Epoxy resin potting glue

Epoxy potting glue has good fluidity and can easily penetrate into the gaps of the product;can Curing at room temperature or medium temperature, moderate curing speed;No bubbles after curing, the surface is smooth, shiny and high hardness ;The cured product has good acid and alkali resistance, moisture-proof, waterproof, oil-proof and dust-proof properties, and is resistant to humidity, heat and atmospheric aging;has good electrical and physical properties such as insulation, pressure resistance, and high bonding strength.

Among them, silicone potting glue is divided into two-component condensation type silicone potting glue and two-component addition type silicone thermally conductive potting glue.

Condensation potting glue is available in transparent, black and white, and is widely used for potting protection of high-power electronic components, module power supplies, circuit boards andLED.

Additional thermally conductive potting glue is gray and is widely used in products with high requirements for heat dissipation, flame retardancy and high temperature resistance, such as: automotive electronics, HIDballasts, power modules, Sensors, circuit boards, transformers, amplifiers.

Shanghai Weigu Provides high thermal conductivitySilicone potting glue, two-component glue, easy to use, has been deeply recognized by new and old customers.

Title of this article: Electronics Industry Three types of potting glue commonly used in the industry

Link to this article: http://www.wellgo.com.cn/newb/information_2352.shtml

微信扫一扫打赏

微信扫一扫打赏