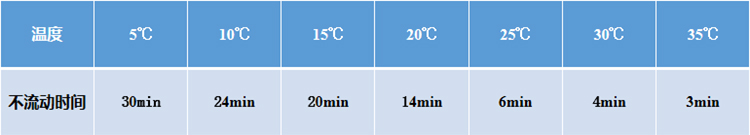

The difference in non-flow time of filter glue at different temperatures

First, let’s clarify the definition of dead time. The no-flow time is the time when the glue and AB materials are mixed and stirred. The time until the glue no longer flows is counted as the no-flow time of the glue. On the customer’s side, it is often called operable time.

Leaves the customer a suitable operating time, which can not only meet the customer’s normal use, It can also improve customers’ work efficiency. Control the operable time , so that the glue can completely penetrate or bond the required profiles. The operable time determines the actual production requirements of the customer,The operable time is usually critical to the customer period. Because, the reaction between the glue injection material and the adhesive will progress to the nextprocess process. Since the next step of the process may be very different, the customer and the manufacturer must agree on the operable time. . Usuallyfor machine glue filling and manual glue filling, or for complex and simple profiles, the operating time requirements will be different. As long as the potting of the profile (especially for mass production) is completed after the specified operating time, the material has reached a certain degree of reaction with a certain hardness. According to customer requirements, the manufacturer can adjust the operable time. Operating times can also be shortened through a temperature-controlled curing process. The various thicknesses of the profile structure or surrounding materials in the profile also have an impact.

PolyurethaneAB glue has a big difference in reaction time at different temperatures. The following is the non-flow time measured at different temperatures for a certain type of filter AB glue product:

Sometimes, customers will encounter that the glue curing time is too slow or even the glue does not work properly. Solidification phenomenon, so why is this? Mainly due to the following reasons:

1. The ratio is out of balance. Manufacturers generally design products in strict accordance with a certain proportion of glue. If there is an excess of raw materials, slow curing will occur. In severe cases, non-curing may occur. According to The glue can achieve the best performance only when the specific ratio is mixed and fully reacted. Therefore, if the proportion is out of balance, the proportion needs to be readjusted.

2. The ambient temperature is too low in winter, resulting in The viscosity of the glue increases, which affects the reaction time. Chemical reaction time is mainly affected by temperature and catalyst. If the operating time is longer due to temperature, there are two ways to solve it. The first is to increase the temperature, and the second is to add catalyst.

3. The glue has failed and the warranty period has expired. If this is the case, the only option is to replace the glue.

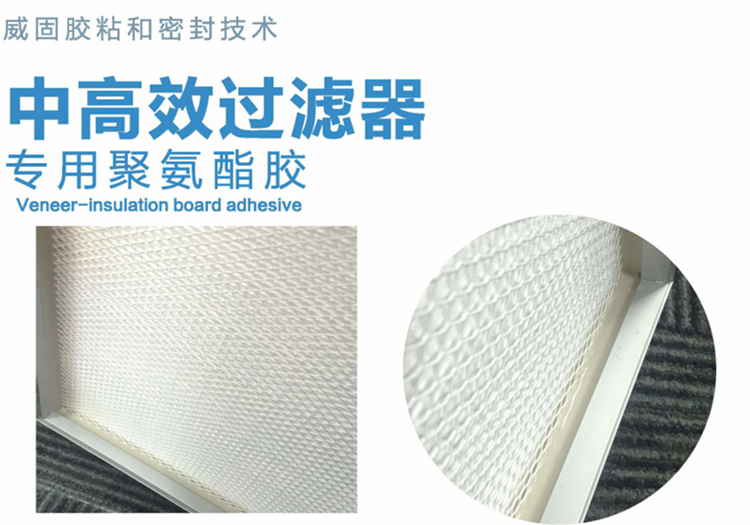

This productproduct is a white, bubble-free, water-free, room temperature curing font>PolyurethaneAdhesive, has High bonding strength, good fluidity, fast solidification, no irritating odorodorCharacteristics. Stability, antiaginge, resistantWaterExcellent performance, suitable for metal materials such as plated plates, aluminum plates, non-passivated stainless steel plates, non-woven fabrics, and filter paper Bonding, filling and sealing between other materials; the product is mainly used font face=”Microsoft Yahei”>With partition, without partition, FFU , V medium and high efficiency filter, Dust removal cartridges and other products. Finished productscomply with ROHS, REACH and other testing standards.

微信扫一扫打赏

微信扫一扫打赏