Space Thermal aluminum profile polyurethane glue injection and bridge cutting machines are the products of our company’s scientific researchers who have been engaged in energy-saving door and window processing for many years

Designed and manufactured after painstaking research and absorbing the advantages of similar products at home and abroad during the production practice

products are efficient, energy-saving and environmentally friendly products that combine hydraulic, pneumatic, electric and computer technologies

reasonable Equipment used together; it is equipment specially used for processing heat-insulating aluminum profiles. Main process: aluminum

Profile→Glue injection machine→Bridge cutting machine. The glue injection machine is a device specially used to inject polyurethane insulation strips into insulated aluminum profiles.

The servo-driven aluminum profile moves smoothly and evenly in the specified direction, and the precise measurement system will A,B Two-component glue ratio

are delivered to high-speed mixing system, stir and inject it into the pouring tank of the aluminum profile, and place it to solidify to

The purpose of connecting the aluminum profiles on both sides is to complete the glue injection process of the heat-insulating aluminum profiles.

The function of the bridge cutting machine is to use a high-speed cutting saw blade to cut off the aluminum profiles that have been glued and solidified

Bottom of the slot At the aluminum joints, retain the cured polyurethane strips so that the polyurethane strips can connect the aluminum profiles on both sides

function to achieve the purpose of heat insulation.

Remarks: The control system and drive system of our equipment are configured by Siemens from Germany, which is very stable

Good and durable! In addition, our equipment also adds alarm systems and counting functions, so choose our products

is your guarantee of quality.

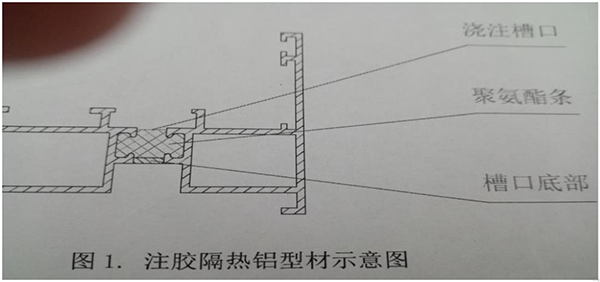

1. Glue-injected heat-insulating aluminum profile

Glue-injected heat-insulating aluminum profiles are polymer liquid A,B After mixing with precise measurement ratio and in strict

It is poured into the aluminum profile pouring slot under the production process. After polymerization and solidification, the aluminum profile joints are cut off to achieve

Aluminum+Polyurethane+Aluminum connection form reduces thermal conductivity and achieves heat insulation effect.

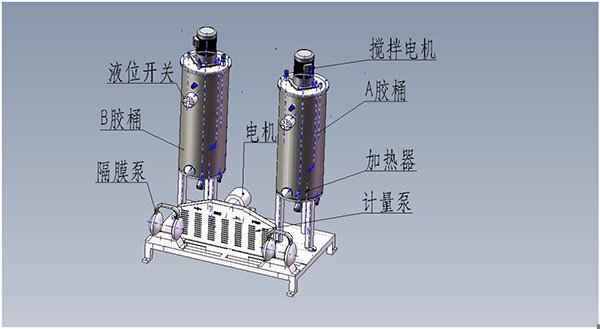

2. Principle of glue injection

A.B Materials are added from the raw material barrel to A.B In the glue bucket, heated to process temperature, A,

The two materials pass through the filter respectively, the metering pump accurately transports them to the glue injection head, and the glue injection hydraulic motor high-speed mixing

Close and pour into the aluminum profile pouring slot through the glue injection nozzle.

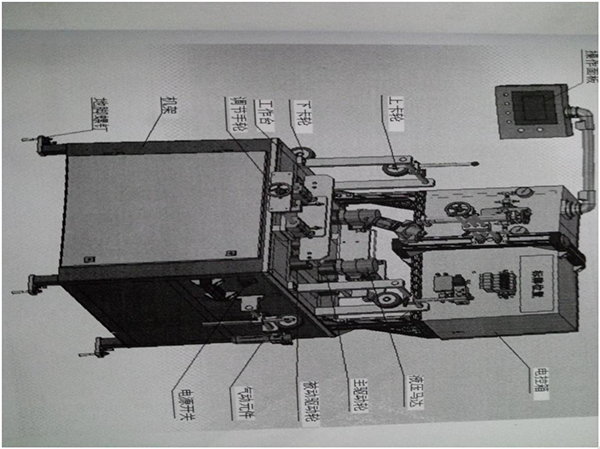

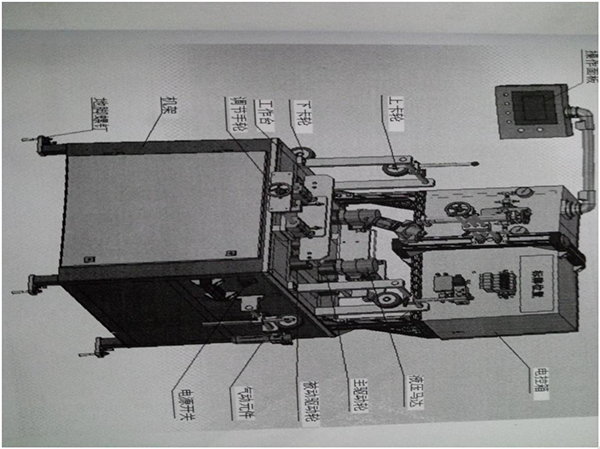

3. One glue injection machine, mainly including servo motor, driving wheel, adjustment device, and electric control boxetc

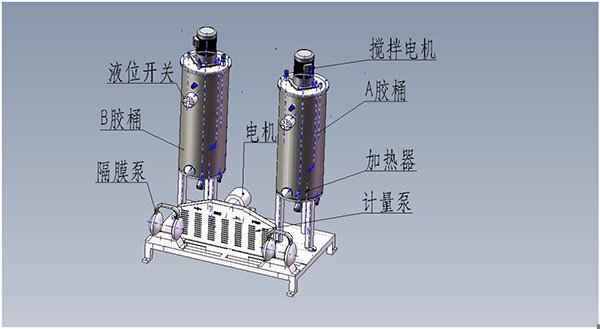

4.A set of feeding heating mixing barrels includes A,B Glue barrel, stirring device, diaphragm pump, heater, liquid level

Sensors, metering pumps, motors, etc.

p>

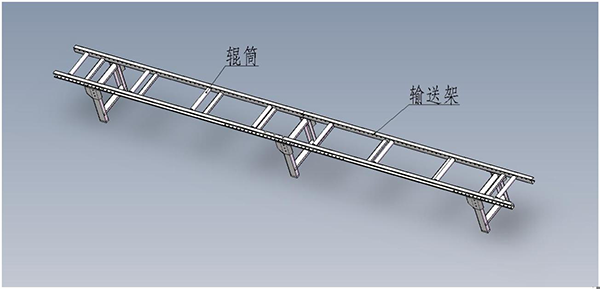

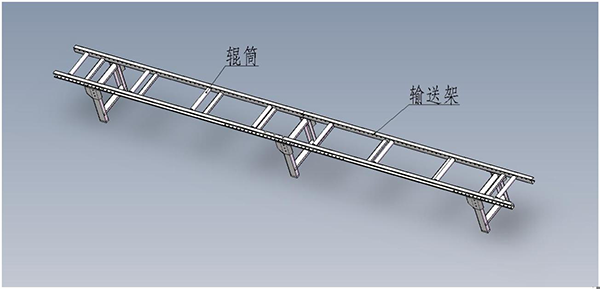

5 , Two sets of conveyor racks, including conveyor racks, rollers, etc.

/font>

Close and pour into the aluminum profile pouring slot through the glue injection nozzle.

3. One glue injection machine, mainly including servo motor, driving wheel, adjustment device, and electric control boxetc

4.A set of feeding heating mixing barrels includes A,B Glue barrel, stirring device, diaphragm pump, heater, liquid level

Sensors, metering pumps, motors, etc.

p>

5 , Two sets of conveyor racks, including conveyor racks, rollers, etc.

微信扫一扫打赏

微信扫一扫打赏