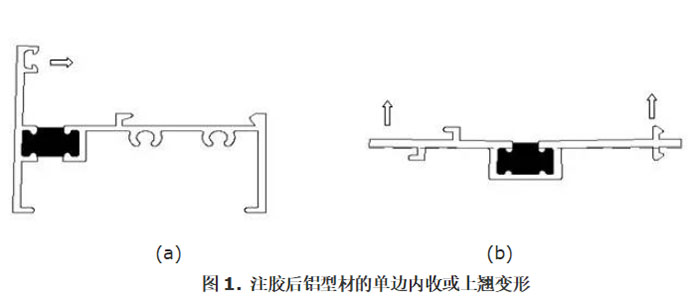

With the requirements of the global low-carbon development situation, the market demand for heat-insulating aluminum profiles is also constantly increasing. expand. As a mature product of thermal insulation and energy-saving building profiles, glue-injected aluminum profiles have gradually become one of the mainstream products in the thermal insulation aluminum profile market due to their high production efficiency and low cost. However, in the industrial production process of the enterprise, if the extrusion production process is produced according to conventional profile control dimensions, the aluminum profiles after injection, especially the casement window series aluminum profiles, are prone to unilateral deformation or upturned deformation in batches. Scrap, as shown in Figure 1.

Then,How to avoid batch scrapping due to deformation after glue injection during the production processWhat about?

1、 Glue injection tank Design

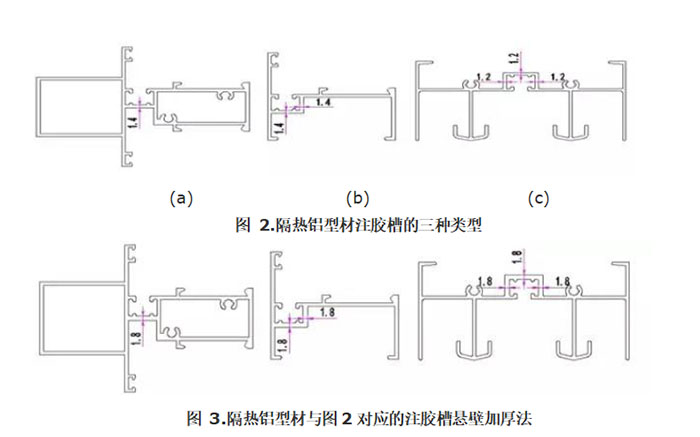

There are three types of glue injection grooves for insulating aluminum profiles. As shown in Figure 2, the improvement method of thickening the wall thickness of the overhanging wall of different types of glue injection grooves is shown in Figure “>3shown. This is an effective method to solve the deformation of glue-injected heat-insulating aluminum profiles. Especially for glue-injected aluminum profiles with thin wall thickness, it is necessary to ensure the stability of extruded materials.

2、Pre-deformation method

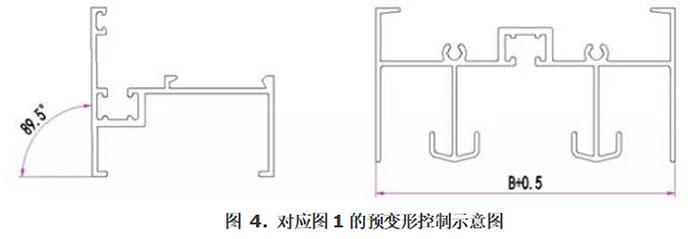

This method is to reserve the deformation amount of the closing mouth after glue injection. When designing the mold and extrusion production, consider the deformation amount in the direction of the glue injection port in advance, as shown in the figure4shown. The amount of pre-deformation during inspection should be controlled according to the different structures of the profile section. The amount of deformation can be reasonably controlled by measuring the angle or opening size.

The processing technology of discharging pre-deformation can be completed through mold repair. If the mold repair is difficult to meet the technical requirements, pre-deformation can be done through mold design. Of course, the final deformation size of the profile after pre-deformation requires the extrusion straightener to reasonably control the stretching rate according to the degree of dimensional change of different profiles when stretching to ensure that the pre-deformation amount requirements of the product are ultimately met.

3、Glue injection process control

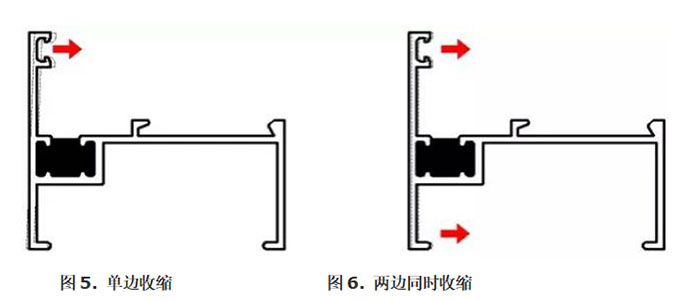

When opening the teeth of the heat-insulating glue-injected aluminum profile, pay attention to adjusting the teeth. Deep, it is advisable to control the tooth depth at around 0.3~0.5mm, and avoid excessively deep tooth openings and excessive pressure,Prevent the profile from beingPressure deformation causes the opening to become larger. The optimal ambient temperature for glue injection is 20~30℃, relative humidity<85%. After the profile is injected with glue, it is required to be placed neatly and without longitudinal bends. The pads between the layers must be vertical up and down. The parking time for glue injection is 10about minutes, the specific parking time is based on the colloid hardness reaching 60 or above as the standard Start cutting the bridge, but you should avoid parking it for too long, which will lead to large and uneven colloid shrinkage, resulting in excessive closing of the profile, and prevent severe shrinkage of one side before the bridge is cut, as shown in the figure 5shown. Control the time for bridge cutting. The amount of shrinkage before bridge cutting is just close to the pre-deformation amount before glue injection. After bridge cutting, the shrinkage of the colloid will be carried out on both sides at the same time, thus stabilizing the shape of the heat-insulating glue-injected profile, as shown in the figure6shown.

The above isTo solve the deformation problem of heat-insulating glue-injected aluminum profiles after glue injection , from the aspects of mold design, extrusion production, glue injection production control, etc., improvements to the glue injection tank cantilever thickening method, pre-deformation method and glue injection process technical conditions were proposed. In addition , The quality of glue will also affect the deformation of aluminum profiles. The curing shrinkage of the glue needs to be controlled within an appropriate range. If the curing shrinkage of the glue is too large, it will be difficult to achieve good results by controlling the above factors. Therefore, when choosing glue, you must choose good quality glue, and the shrinkage rate must be within the index range.

Note: This article is compiled and provided by Shanghai Weigu Chemical Products Co., Ltd. Shanghai Weigu Chemical Products Co., Ltd. specializes in the production of injection-type aluminum profile insulation glueand broken bridge insulation glue injection equipment, it is the only company in the country that simultaneously produces bridge broken aluminum profile glue and glue injection equipment. It is your An ideal strategic partner! Welcome to negotiate.

微信扫一扫打赏

微信扫一扫打赏