On October 26, Huibai New Materials issued a public initial public offering of stocks and listed its prospectus on the GEM. Huibai New Materials issued a public offering of 23.0667 million shares, accounting for 25.00% of the total share capital after the issuance. , all the shares issued this time are new shares issued to the public, and the company’s shareholders will not conduct public sales. The issue price is 22.88 yuan. The sponsor for this issuance of Huibai New Materials is Dongxing Securities Co., Ltd. Huibai New Materials is a company located in Shanghai that develops, produces and sells epoxy resin series products. Its products include epoxy resin for wind turbine blades, epoxy resin for new composite materials, epoxy resin for electronic and electrical insulation packaging, etc. application series products. In addition, the company also sells a small amount of products such as quantum dot color conversion ink for Mini\MicroLED and provides customers with related solutions and services for quantum dot applications.

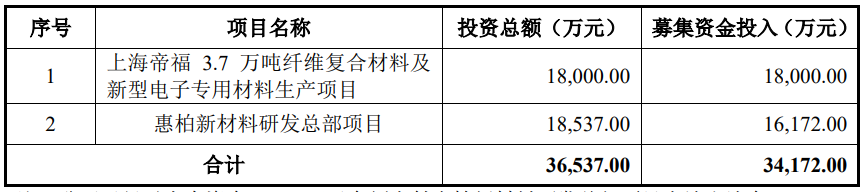

The prospectus disclosed by Huibai New Materials on October 26, 2023 shows that the company plans to raise 342 million yuan for Shanghai Defu’s 37,000-ton fiber composite material and new electronic special materials production project and Huibai New Materials R&D headquarters project .

Shanghai Defu 37,000-ton fiber composite materials and new electronic special materials production project

Except for new

In addition to extending the 2,000 tons of fiber composite products to downstream products, this project is mainly for the expansion of the company’s existing products, including the addition of 30,000 tons of epoxy resin for wind turbine blades, 4,998 tons of epoxy resin for new composite materials, and 2 tons of epoxy resin for new composite materials. Quantum dots are new display materials.

The implementation of Shanghai Defu’s 37,000-ton fiber composite material and new electronic special materials production project can effectively solve the shortage of existing business sites, improve production and operation hardware facilities, break through production bottlenecks, improve operating efficiency, and at the same time help the company optimize and update products structure to enhance the company’s industry status and competitiveness.

Huibai New Materials R&D Headquarters Project

In order to meet the company’s medium and long-term strategic development plan and continue to enhance the company’s R&D strength and technical level, the company plans to invest in the construction of an R&D headquarters. This project relies on the company’s years of technology accumulation in the field of special formula modified epoxy resin. It will strengthen the company’s field of special formula modified epoxy resin and downstream products by adding advanced equipment, absorbing high-end talents, and improving the personnel gradient structure. Research. In addition, this project will also effectively enhance the company’s product development and testing capabilities, effectively help the company’s products be used in a wider range of downstream fields, enhance independent innovation capabilities, accelerate the industrialization process of scientific research results, transform technical soft power into product competitiveness, and enhance The company’s overall competitive strength has laid a more solid technical foundation for the company’s future market expansion.

Huibai New Materials R&D Headquarters Project will significantly enhance the company’s R&D capabilities and enhance the company’s R&D capabilities in new materials such as specially formulated modified epoxy resins. By building a more advanced R&D platform, the company will continue to carry out technological innovations in new material products such as specially formulated modified epoxy resin and enrich the company’s product structure.

The investment project with funds raised this time is closely centered on the company’s main business, focusing on improving the company’s operating hardware facilities, improving technology research and development levels, enhancing the company’s core competitiveness, further improving the company’s production capacity, optimizing product structure, consolidating and improving the company’s The industry status of special formula modified epoxy resin will not lead to changes in the company’s main business. The construction of the proposed investment project will expand the company’s scale, enhance independent innovation capabilities, and further improve the company’s profitability and overall competitiveness.

Main business operations

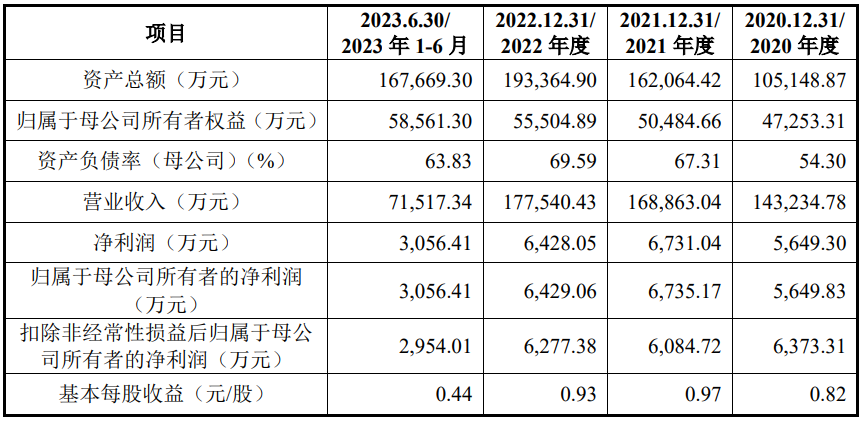

According to the prospectus, the company’s operating income increased from 1.432 billion yuan to 1.775 billion yuan from 2020 to 2022. From January to June 2023, the company achieved revenue of 715 million yuan; net profit attributable to the parent company was 30.5641 million yuan; net profit attributable to the parent company after non-deduction was 29.5401 million yuan.

Future Development Plan

In order to achieve the goal of becoming a leading composite material solutions provider, in addition to consolidating and expanding the existing wind power blade market share through research and development and promotion of epoxy resin for offshore wind power and large-megawatt wind power blades, the company will also focus on research and development and promotion of resistive materials. Epoxy resin for fuel-burning composite materials, epoxy resin for prepregs, epoxy resin for lightweight composite materials for new energy vehicles, epoxy resin for energy storage and hydrogen storage safety composite materials, and epoxy resin for new composite materials such as quantum dots Related products, high-end adhesive materials, composite resins for aramid fibers and other products, in order to achieve a business structure with diversified mainstream products, diversified operating income, and decentralized downstream customers.

(1) Epoxy resin for offshore wind power and large-megawatt wind power blades

With the development of “affordability” of wind power, the development trend of large-megawatt offshore wind power has become more and more obvious. The company has developed a variety of epoxy resins suitable for high-power offshore wind power blades. The existing products have been applied in batches of 5-8MW offshore wind power blades. , the company has currently targeted environmental protection for wind turbine blades with 8-15MW and blade lengths exceeding 100 meters in the future.�Resin has made an overall technical plan.

(2) Epoxy resin for flame retardant composite materials

The large-scale application of composite materials is inevitable for the development of rail transit technology and composite material technology. The trend can be summarized as the application of composite materials develops from non-load-bearing parts to main load-bearing parts, and the application of structural composite materials develops to the simultaneous application of structural/functional composite materials; The preparation process has evolved from hand lay-up to vacuum introduction, prepreg molding and other directions; the resin-based material will shift from unsaturated polyester to environmentally friendly, low-odor, high-efficiency flame-retardant epoxy resin; due to its low odor, low volatility, Environmentally friendly features, epoxy resin-based composite materials can greatly improve the volatilization of prohibited and restricted substances in the vehicle and reduce harm to the human body, and composite structures such as honeycomb sandwich structures, foam sandwich structures, functional laminates, etc. will become railway systems and The focus of research and development on high-speed trains, epoxy resin-based composite materials can better realize the application of this new process and new technology. The company continues to carry out in-depth research on the field of epoxy resins for flame-retardant composite materials, constantly improves and optimizes formulas, and has successively developed a variety of epoxy resins for flame-retardant composite materials that meet the application requirements of downstream fields, and continues to develop and innovate.

(3) Epoxy resin for prepreg

In order to achieve an effective combination of epoxy resin and carbon fiber, the company has designed a new formula for the carbon fiber prepreg system resin. At the same time, the main material has been modified and specially processed so that it can be effectively combined with the carbon fiber and give full play to the performance of the carbon fiber. , at the same time, the medium-temperature system of epoxy resin for prepregs has been improved and extended, and epoxy resins for prepregs with low-temperature curing, rapid curing, high toughening, and high temperature resistance systems have been designed and developed, which has greatly expanded the scope of prepregs. Application fields and markets of epoxy resin for materials.

(4) Epoxy resin for lightweight composite materials for new energy vehicles

In order to seize the business opportunities of the rapid development of new energy vehicles in recent years, the company uses the promotion of composite material technology for new energy vehicles as a means to provide end customers with a complete set of composite material solutions for this industry. In addition to inheriting the lightweight properties of traditional carbon fiber materials such as lightweight, high strength, high modulus, corrosion resistance, fatigue resistance, and low density, new advanced process technology and special epoxy resin systems continue to make carbon fiber composite materials recyclable and recyclable. Characteristics such as rapid prototyping, environmental protection and low volatility expand the application characteristics of carbon fiber composite materials and increase the added value of the product.

(5) Epoxy resin for energy storage and hydrogen storage safety composite materials

As a new clean and efficient energy source that can replace fossil fuels, hydrogen energy’s application technology is developing rapidly. The new direction for the research and development of hydrogen storage materials in the future is to develop safe and efficient composite hydrogen storage materials as a premise to achieve large-scale preparation and production of hydrogen storage materials. Can be recycled. The company actively cooperates with domestic and foreign wound gas cylinder partners to develop low-cost, low-temperature curing, and fast-curing epoxy resin formulas to meet the future market needs and applications in the field of carbon fiber wound gas cylinders.

(6) Quantum dot related products

With the gradual popularization and application of OLED, people’s expectations for the color of display screens have been raised. In the future, screens will also develop in the direction of energy saving, high color gamut, high contrast and high-efficiency production. The quantum dot related products developed by the company are designed to be used with MiniLED, MicroLED and OLED to solve the problems of slow aging and yield (especially red light), repair and cost threshold of existing MiniLED three-color LED chips, and solve the problem of MicroLED’s high color Address domain cost issues and improve OLED display effects. Therefore, the company is actively developing quantum dot color conversion ink with inkjet printing technology, quantum dot glue for automatic dispensing, and quantum dot lenses, etc., which can cope with future advanced processes and current traditional processes respectively, and can achieve improvements under effective cost control. Display color gamut contrast function.

(7) High-end adhesives

The company has initially developed a thermosetting adhesive and expects to gradually complete other varieties of thermosetting and light-setting adhesives in the next two years to achieve high-quality domestic electronic adhesives to enter the field of camera lens module bonding; at the same time, The company is also working on the development of vehicle-mounted flame-retardant and explosion-proof relay edge-sealing adhesives to meet the needs of the new energy vehicle market. In addition to the above-mentioned products, the company is also actively developing composite resin product formulas for aramid fibers, and is deploying epoxy adhesive films and other related products.

微信扫一扫打赏

微信扫一扫打赏