Bostik, the world’s leading adhesives expert, launches a new range of thermally conductive adhesives (TCA) to address the latest Cell-to-Pack (CTP) requirements in electric vehicle solutions

Thermal management challenges in battery design.

Bostik’s new thermally conductive adhesive will address thermal management challenges faced by the latest Cell-to-Pack (CTP) battery designs in electric vehicle solutions

Ms. Liu Mo, Director of Mobility Business of Bostik Asia Pacific, said: “We have been committed to working with industry experts to provide customers in the electric vehicle (EV) battery market with innovative thermal interface materials.

(TIM) solution. ”

As we all know, Bostik is a member of the Arkema Group. In June 2023, Arkema acquired Polytec

PT., a German company specializing in adhesive solutions for battery and electronics applications.

“Bostik’s recent collaboration with Polytec PT brings Bostik’s expertise in structural polyurethane adhesives to Polytec PT

A powerful combination of expertise in thermally conductive materials,” Ms. Liu Mo added.

China is the world’s largest electric vehicle market, with sales of electric vehicles reaching 5.9 million in 2022, accounting for 1% of global electric vehicle sales.

59%, and continues to grow at an unprecedented rate. Based on such strong growth momentum, automobile manufacturers are vigorously carrying out technological upgrades to meet drivers’ needs for a smoother and safer driving experience.

As electric vehicle technology develops, there is an increasing demand for more reliable and effective adhesives that protect batteries.

Battery modules are the core component driving this need. Every aspect of driving affects battery life and performance. Climate control helps protect battery health by maintaining the required temperature while the battery is charging. TCA

Not only does it bond parts together, it also dissipates heat effectively, so it’s the best solution to this problem.

November 9, 2023, Bostik

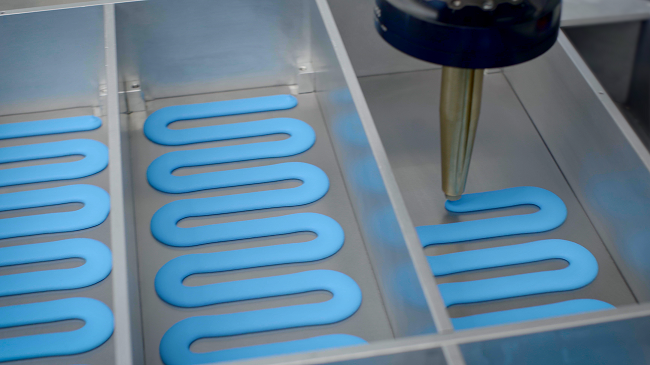

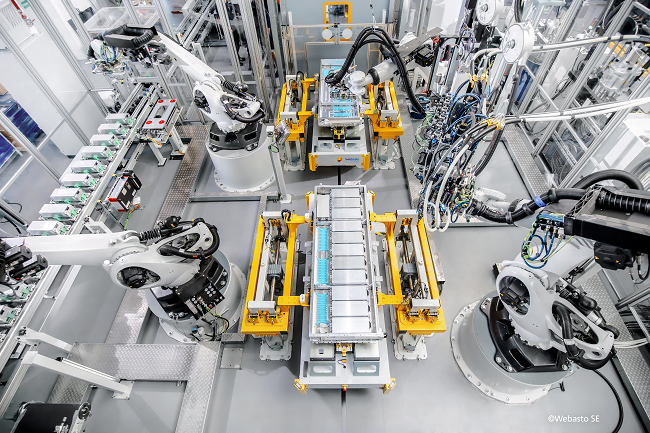

The “Innovation Day” event will be co-organized with Dürr in Shanghai, China, and many cooperation results between the two parties will be displayed at this event. The theme of this event is “Innovative Application of Thermal Conductive Materials in Automatic Battery Assembly” and will focus on electric vehicle batteries.

Innovative application technologies developed by Dürr provide comprehensive solutions for battery gluing. “The entire battery system is our focus,” said Dürr. “Crash safety is important, but so are weight and service life.” Dürr’s modular bonding technology ensures that adhesives and sealants are applied precisely and evenly Distributed in a completely sealed environment. This protects the battery cells from vibration and ensures optimal heat conduction.

Thanks to the collaboration between Dürr and Bostik, the TCAs developed are available in various viscosities and mixing ratios, offering flexibility and adaptability for more effective thermal management.

Bostik is committed to developing next-generation engineering adhesives and optimizing battery life for more efficient battery charging systems

Thermal management is critical to ensuring that the operating temperature of electric vehicle battery systems remains between 20°C and 40°C for optimal battery life and performance. TCA etc TIM

Critical to battery design, it ensures a more robust thermal connection between the battery/cell environment and cooling elements. As fast charging of electric vehicles becomes a trend, the importance of thermal management and TIM is becoming increasingly prominent.

Ms. Liu Mo said: “The rapid growth of the electric vehicle market urgently requires batteries with higher efficiency and better performance.” Bostik is keenly aware of the urgent need for efficient adhesives from electric vehicle manufacturers and takes the initiative to work with them.

Polytec PT carries out strategic cooperation and develops a wide range of products to meet industry needs.

New XPU TCA 202

It is a two-component polyurethane-based adhesive specially used for heat dissipation of battery pack components. The product’s thermal conductivity is perfectly balanced with high mechanical strength and it maintains good flexibility due to its high elongation. It contains very low monomer content, meets the most stringent regulatory requirements, and is easy to use without special training. At the practical application level, this product can be processed quickly and easily through automatic mixing, dosing and dispensing equipment. The adhesive bonds well to most substrates without the use of primer and cures at room temperature.

In addition, Bostik offers a range of silicone-free thermally conductive caulks specifically designed to ensure heat exchange between battery modules and cooling plates as well as power electronics. Like VP2106-408

Such a one-component non-reactive thermally conductive caulking agent is a silicone-free and removable filler. This feature ensures that the equipment can be easily disassembled for recycling and repair. and

The product also reduces costs associated with mixing and dispensing equipment compared to two-component alternatives.

Two-component SMP thermally conductive caulking agent series���A two-component injection SMP thermally conductive caulking agent, also known as

GF300LV. The technology excels in high-volume injection processes and rapid compression due to its precisely optimized viscosity, enabling efficient, fully automated modular manufacturing. Additionally, the range is silicone-free and VOC-free

(VOC) and has low wear properties.

With the rapid growth of demand for electric vehicles, the requirements for battery performance are also getting higher and higher. Bostik is committed to developing a new generation of engineering adhesives to continuously optimize battery life to achieve more efficient battery systems.

微信扫一扫打赏

微信扫一扫打赏