Sending happy news in golden autumn, SABIC

Develop new technologies for electric vehicle battery design, adding another big boost to the rapidly growing electric vehicle industry! Recently, SABIC announced that the first molding test of the electric vehicle battery cover mold was a complete success!

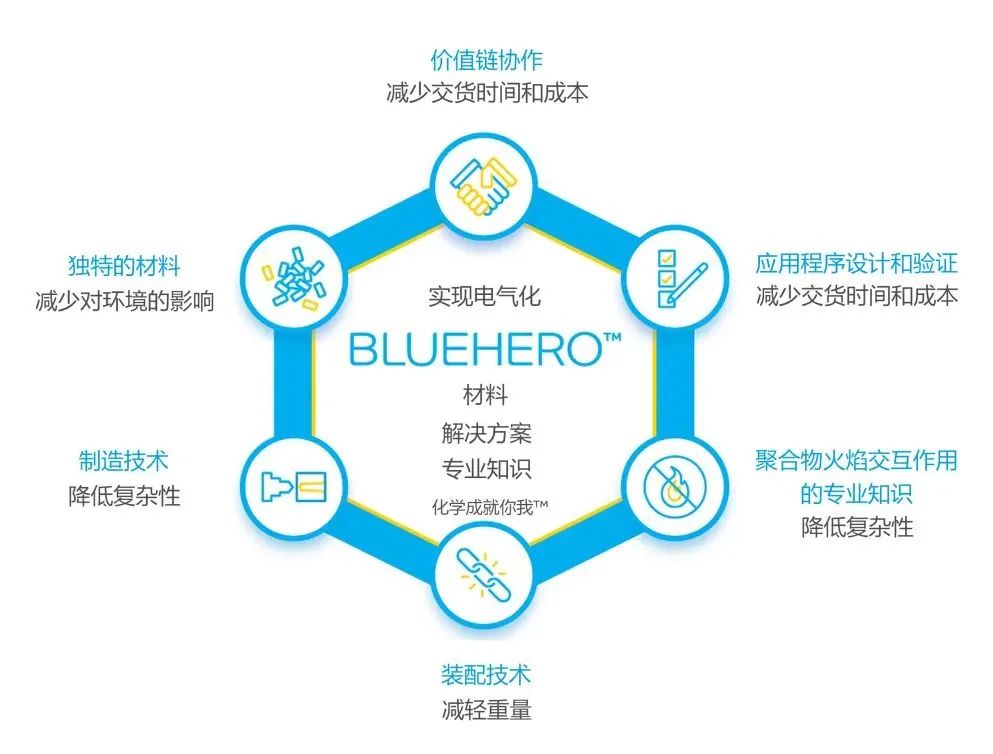

SABIC launched the BLUEHEROTM program last year, covering a variety of materials, solutions, expertise and custom projects, aimed at accelerating energy transition to electrification and actively responding to global climate change.

Under the program, SABIC has introduced a solution for the manufacture of large-scale components for electric vehicle batteries through a thermoplastic injection molding process. After preliminary molding tests, the battery cover mold has successfully achieved a series of major achievements:

Clear molding lines and perfect hole shapes

Mold opening and closing smoothly

excellent surface treatment

Part flatness

Smooth molding process (no sticky mold)

Based on this exciting molding test, the SABIC team will continue to develop how to use low-pressure injection molding technology to control the clamping force and reduce warpage, and will also focus on how to meet the industry’s requirements for dimensional tolerances and limited design space.

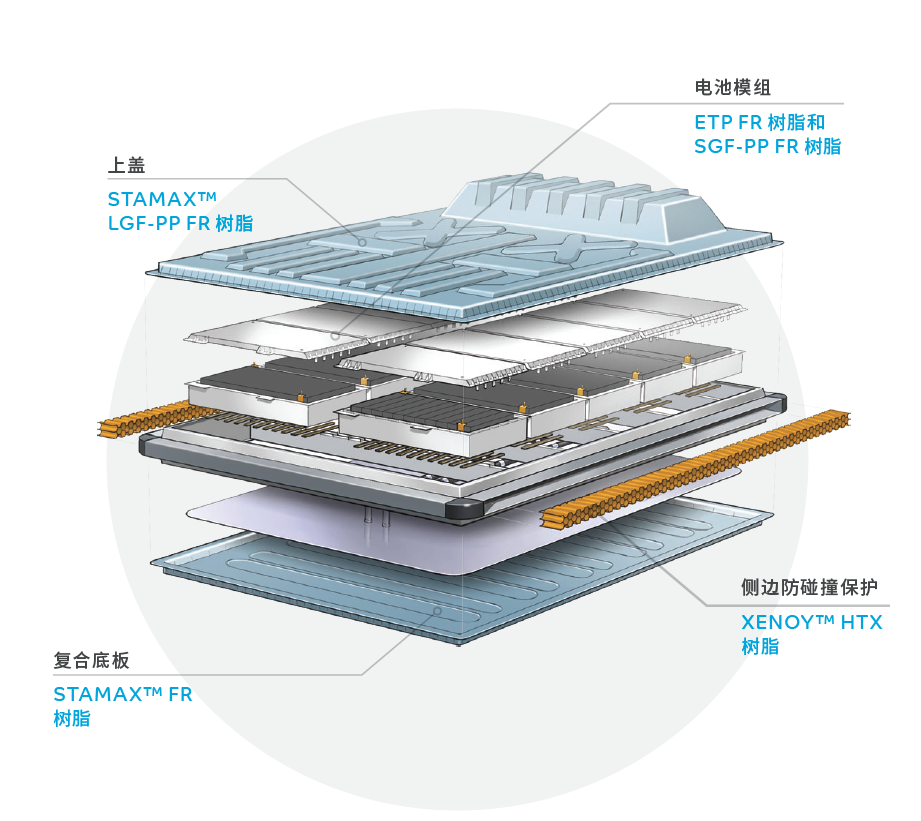

As we all know, the battery pack is the power source of new energy vehicles, and the main body of the battery pack is formed by covering the battery module with the casing. The battery case plays a key role in the safe operation and protection of the battery module, and its materials are required to have the characteristics of corrosion resistance, insulation, resistance to shock at room temperature and low temperature, and flame retardancy.

The battery casing is composed of two parts, the upper casing and the lower casing. The upper casing is the upper cover, and its main function is to protect, seal and isolate it from the car compartment.

The battery cover mold can not only reduce the complexity and weight of electric vehicle batteries, but the specific injection molding and injection compression molding processes adopted by SABIC can also save energy and reduce emissions, thereby reducing the impact on the environment. In addition, the upper cover material includes flame-retardant thermoplastics, which also contribute to heat insulation and enhance the functional integration of the battery.

As an innovative technology in the industry, the special form of injection molding can meet the large size and functional requirements of the upper cover, which is suitable for the mass production situation of future electric vehicles. Based on its growing expertise and thermoplastic capabilities in the field of electric vehicles, SABIC will continue to vigorously develop the injection molding process for large parts of the battery cover of electric vehicles.

微信扫一扫打赏

微信扫一扫打赏