CCUS (carbon dioxide capture, utilization and storage) is often called the “last line of defense for carbon neutrality” and is also used by petrochemical companies (petroleum, petrochemicals, coal) and high-carbon emission companies that are highly dependent on fossil energy (thermal power, steel, construction) An important way for companies to achieve carbon neutrality. Since China’s current power structure is still highly dependent on thermal power, and the change in the energy structure will not be particularly significant in the short term, the importance of developing CCUS is self-evident.

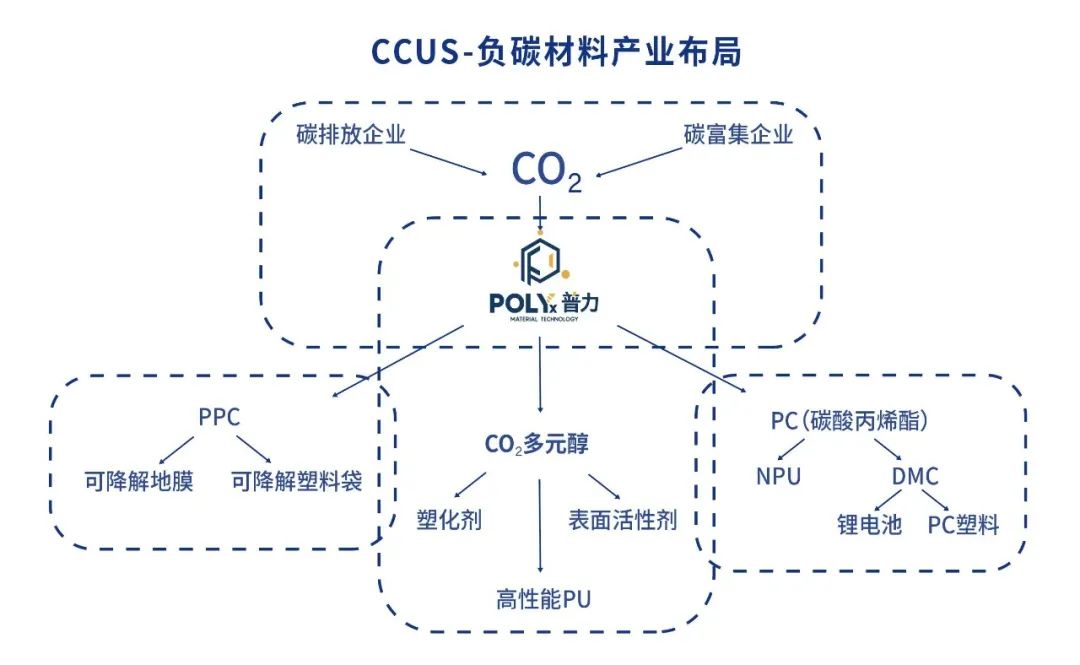

Hefei Puli Advanced Materials Technology Co., Ltd. (hereinafter referred to as “Puli Materials”), as one of the few companies in the CCUS field that has mastered high-value carbon utilization technology that is ready for industrialization, has focused on carbon dioxide utilization technology since 2017. , independently developed catalytic synthesis technology for carbon dioxide-based materials. The carbon dioxide mass fraction of the carbon dioxide-based materials produced by the company can reach more than 30%. The introduction of carbon dioxide greatly reduces the dependence of synthetic materials on petrochemical raw materials, reduces direct carbon emissions in the field of material synthesis, and achieves carbon neutrality while creating extremely high economic value.

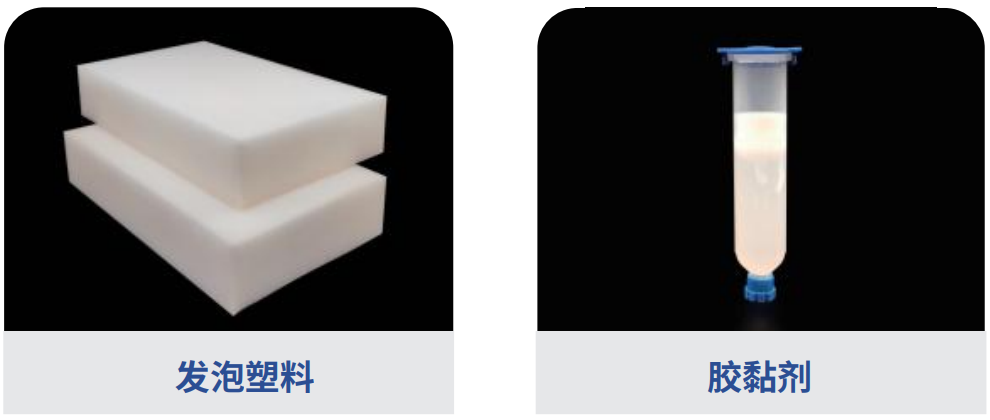

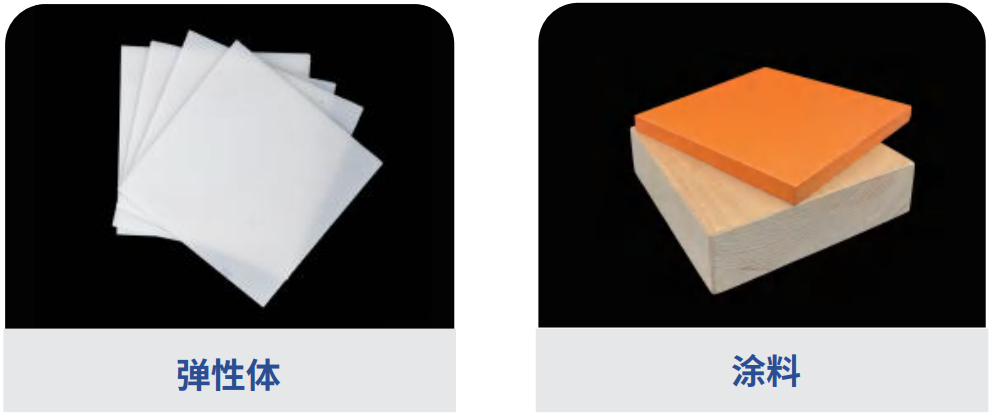

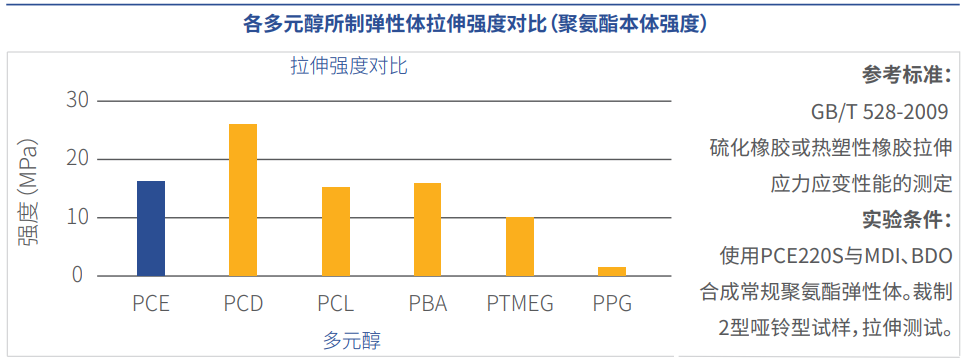

Lower carbon footprint and better performance are often difficult to achieve at the same time, and Puli Materials’ carbon dioxide polyol (PCE) achieves the perfect balance of low carbon and performance. Compared with using traditional polyol raw materials, polyurethane products prepared with PCE as raw materials can effectively reduce carbon while showing better performance.

Hefei Puli Advanced Materials Technology Co., Ltd.

Hefei Puli Advanced Materials Technology Co., Ltd. is a high-tech enterprise engaged in the research, development and production of high-performance new materials synthesized from greenhouse gas carbon dioxide as raw material. The company was founded in 2017, and the core team is all from Zhejiang University. The company has independent intellectual property rights in new carbon dioxide material polymerization technology, and its core product is carbon dioxide polyol PCE.

With carbon dioxide utilization technology as its core competitiveness, Puli Materials is committed to becoming the world’s leading manufacturer of carbon dioxide polyols and promoting the development of the carbon dioxide-based polyurethane industry. At the same time, we will thoroughly implement the country’s major strategic decisions on carbon peaking and carbon neutrality, and implement the carbon peaking action before 2030.

Core product: CO₂polyol PCE

What is PCE?

The raw materials of PCE are carbon dioxide and propylene oxide. It is a random block copolymer of polycarbonate and polyether. Its overall performance characteristics are close to those of polycarbonate polyol PCD. The molecular weight distribution of the product is less than 2, the functionality can be 2 or 3, and the carbon dioxide mass fraction is greater than 30%. The product not only has high comprehensive mechanical properties and weather resistance, but also conforms to the country’s carbon neutral policy guidance.

The carbon dioxide mass fraction exceeds 30%

Puli Material’s CO₂polyol PCE products use carbon dioxide as raw material, and its fixed amount (mass fraction) can reach more than 30%, surpassing the products of similar companies at home and abroad. The carbon neutralization effect of PCE products is remarkable. At the same time, the proportion of carbonate structure in the product can reach up to 70%, and the overall performance is close to that of polycarbonate polyols.

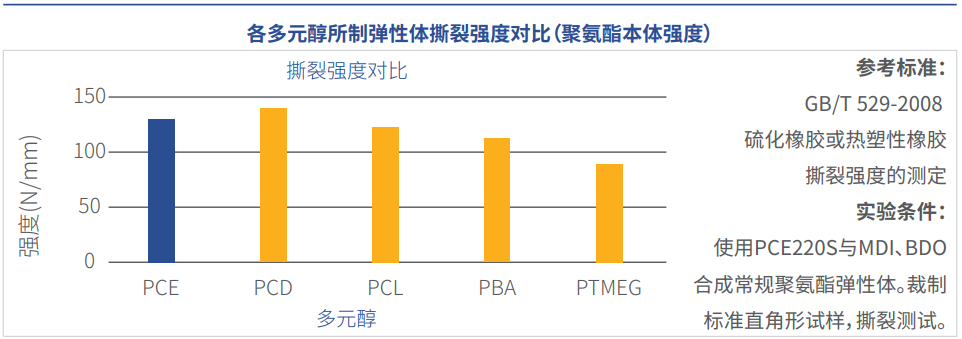

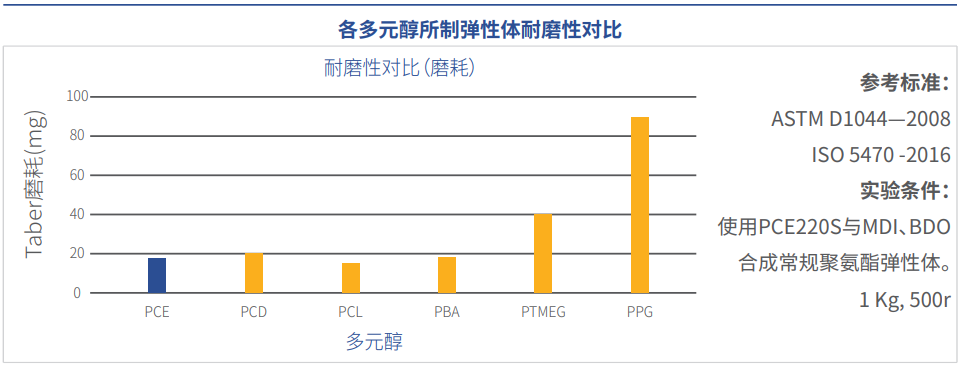

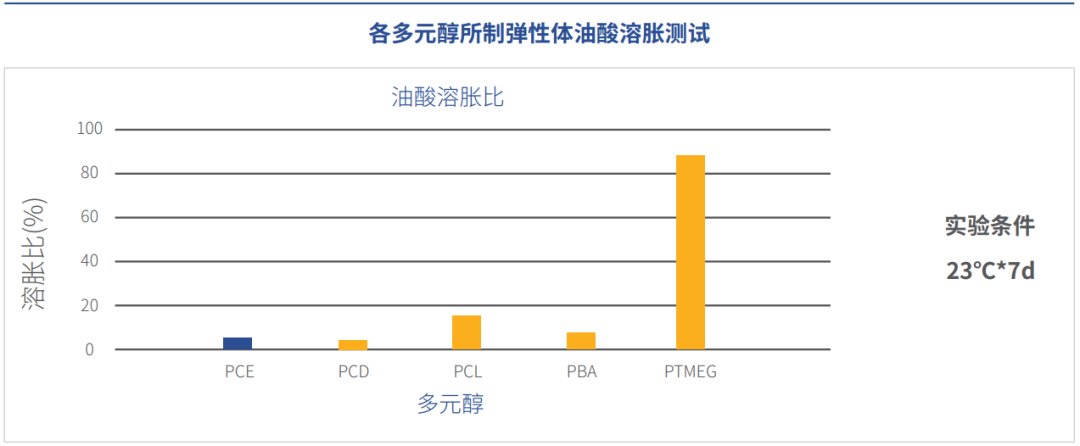

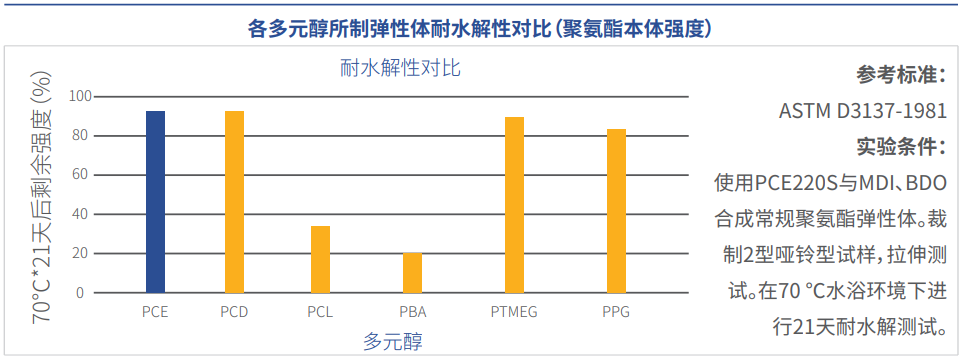

Part of the performance when applied to polyurethane elastomer

300,000 tons/year production capacity launched in Anhui

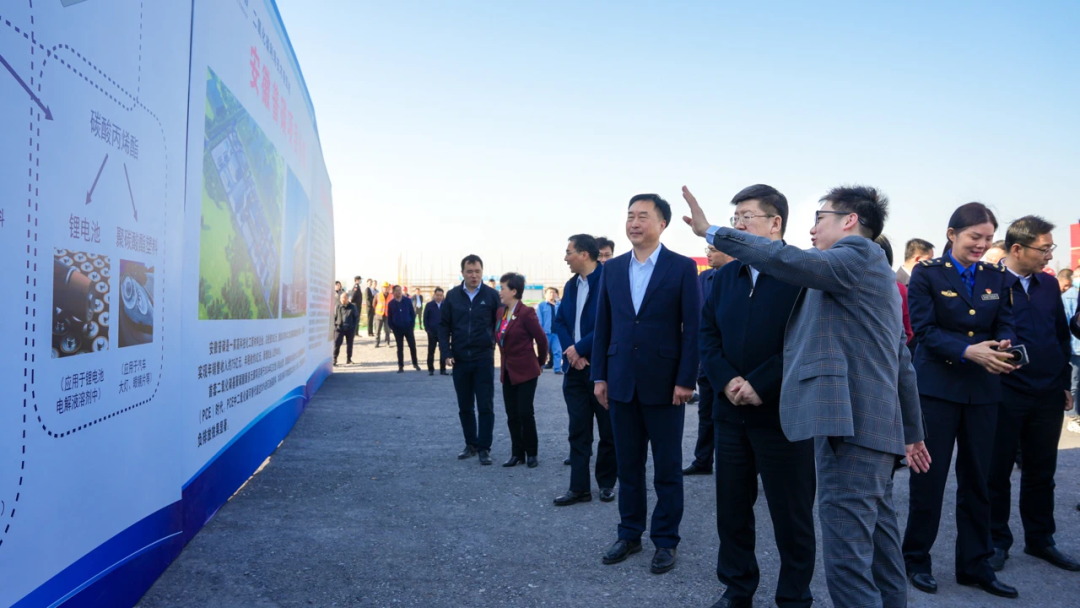

On March 14, 2023, the 300,000-ton carbon dioxide polyol project invested and constructed by Puli Materials with an annual output of 300,000 tons was officially launched in Anhui (Huainan) Modern Coal Chemical Industrial Park. After completion, it will become the country’s first large-scale carbon dioxide polyol production base. At the same time, it will work with many companies in the park to build a CCUS demonstration base to realize the integration of the entire industry chain of carbon dioxide emissions, capture, utilization, and storage, and help Huainan Zero Carbon Industrial Park achieve new breakthroughs.

Mao Hongbing, Chairman of Puli Materials, introduced the project status at the groundbreaking ceremony

The project belongs to the core carbon utilization category of the industrial chain of carbon dioxide emission, capture, utilization and storage in the zero-carbon industrial park. It plays a connecting role in the park and can form the carbon dioxide of Zhongan United-Jinhong Gas-Anhui Putan. The capture and processing chain radiates downstream to companies such as Saiwei Electronics, Xiangsheng New Materials, and Zhuoan New Materials in the park to form a carbon dioxide utilization chain. Such integration and connection of the entire industry chain not only brings stability to the companies in the industry chain The cash flow can more effectively save transportation and other aspects of costs, and comprehensively improve the gross profit of each company. More importantly, the integrated industrial chain is more competitive in the industry and can effectively occupy relevant markets.

The project is constructed in two phases, with an investment of 600 million yuan in the first phase, with an annual output of 50,000 tons of carbon dioxide polyols and propylene carbonate. It is expected to be completed and put into production by the end of 2023. After reaching production, it can achieve annual sales revenue of approximately 1.5 billion yuan. The second phase investment is 1.4 billion yuan, with an annual output of 250,000 tons of carbon dioxide polyols and propylene carbonate. Construction will start in 2024. After completion and production, annual sales revenue of 6 billion yuan can be achieved.

微信扫一扫打赏

微信扫一扫打赏