Green environmental protection and sustainability have always been a common goal of the textile industry. Especially in recent years, driven by the global “carbon neutrality” trend and related policies, brands urgently need sustainable materials to reduce their carbon footprint. , companies have therefore increased their efforts to develop low-carbon materials, zero-carbon materials and even “carbon-negative” materials. Jiangsu Yaodi New Materials Co., Ltd. is one of them.

Carbon negative materials refer to materials that actually reduce greenhouse gas emissions during use. During their entire life cycle, they remove more carbon from the atmosphere than they release. Polypropylene carbonate (PPC) is carbon negative. Material.

Using carbon negative materials to prepare waterproof and breathable membranes

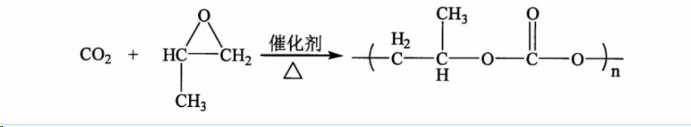

Polypropylene carbonate (PPC) is directly copolymerized from industrial waste carbon dioxide and propylene oxide. It does not compete with the population for food. It is biodegradable and has good biocompatibility. Therefore, it was initially widely used in food packaging and agriculture. Film and other fields. Can such materials be used in textiles? The answer is of course yes.

PPC synthesis route

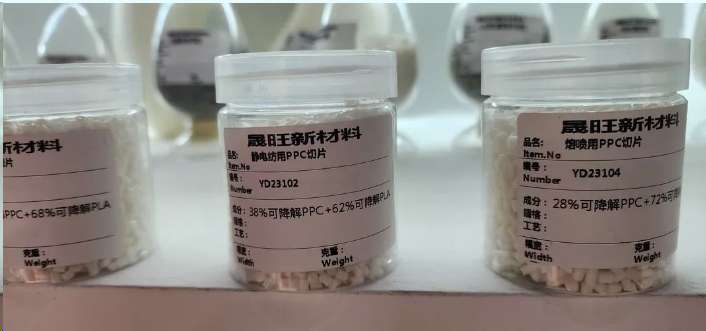

PPC+PLA modified slices for medical, spunbond, electrospinning and meltblown use

According to Huang Guangyao, general manager of Jiangsu Yaodi New Materials Co., Ltd., polypropylene carbonate has a low melting point, soft material, and poor thermal stability, so it first needs to be modified. Yaodi New Materials melt-blends polypropylene carbonate and polylactic acid (PLA).

On the one hand, it improves the strength and thermal properties of polypropylene carbonate,

On the other hand, the flexibility and gas barrier properties of PLA can also be improved, and the composite still has considerable biodegradability. The product being developed by Yaodi, the nanofiber waterproof and breathable membrane, is applied to the modified negative carbon material PPC.

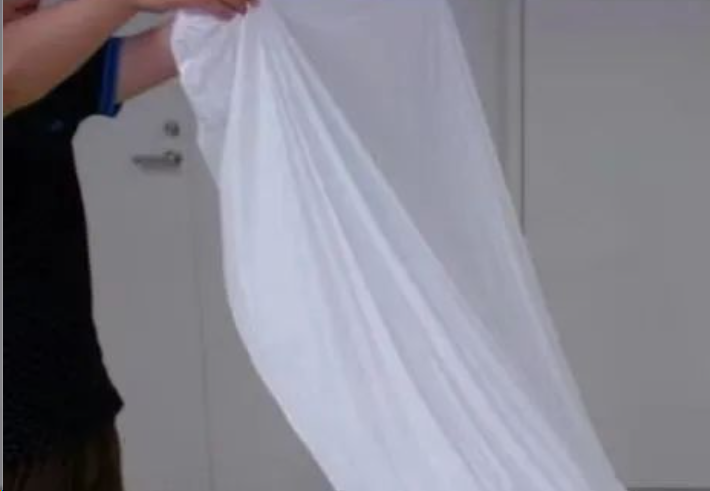

Yaodi’s PPC nanofiber waterproof and breathable membrane

The nanofiber waterproof and breathable membrane is prepared by electrospinning. The weight of the membrane is about 10g, the moisture permeability exceeds 15000g/(㎡·24h), and the water pressure resistance reaches 8000mmH2O. Therefore, it can be applied to sports jackets and jackets. In the process of developing PPC waterproof and breathable membrane, Mr. Huang revealed that the biggest problem encountered was that PPC has too good elasticity (elongation at break reaches 196%), and the stability after film formation is easily affected. After many attempts, Yaodi slowly overcame this problem.

We must firmly control research and development in our own hands

Yaodi New Materials was established in 2011. It is a comprehensive enterprise focusing on the research and development, design, production, sales and service of new materials and functional products. It has more than 100 circular machines and nano powder production lines, and cooperates with Tongji University, Donghua University, Nantong University, Jiangsu Province Nantong Textile and Silk Industry Technology Research Institute and other universities have established industry-university-research cooperation bases. Mr. Huang mentioned that Yaodi New Materials started with flame retardant products, from permanent flame retardant yarns to permanent flame retardant fabrics. It was one of the first companies in China to issue a “Corporate Standard Certificate” for flame retardant products. In recent years, based on customer needs, Yaodi New Materials has continued to develop and launch a series of new products such as cold-insulating super down, ultra-fine polyester ultra-high row health cloth, bionic anti-adhesion, anti-bacterial, anti-viral and anti-thrombotic products.

“R&D is the primary productive force, and we must firmly control R&D in our own hands!” Thanks to its own nanopowder production line, Yaodi has conducted many explorations and innovations in material modification. In addition to common polyester and nylon modifications, Yaodi is currently also modifying polylactic acid (PLA) and bio-based nylon PA56. By adding super cooling, heat-storage, collagen, antibacterial, antiviral, mosquito repellent and other powders, we endow sustainable fabrics with permanent properties.

Use micro-innovation to increase the added value of products

When asked about the current situation and development trends of the textile industry, Mr. Huang said with emotion: “In ‘clothing, food, housing and transportation’, ‘clothing’ ranks first. The textile industry is a sunrise industry, not a sunset industry. The key is to build on its own foundation.” Carry out some micro-innovations to increase the added value of products. Especially small and medium-sized enterprises like us must follow the current market trend of green and environmental protection and constantly launch functional and differentiated products that meet customer needs to make customers feel that they are worth their money. .”

Yaodi New Materials is determined to become a benchmark enterprise in the technological textile industry. Polypropylene carbonate (PPC) is the product they have transferred from the initial fields of disposable tableware, food packaging, degradable foam and disposable medical and industrial applications to textiles. A “micro-innovation” in the field. In addition, PPC foam can also be made into headrests, mattresses, etc. PPC also has intrinsic flame retardant properties. Mr. Huang said that in addition to its application…In addition to the waterproof and breathable membrane, it will be expanded to yarn in the future to develop more functions and uses.

微信扫一扫打赏

微信扫一扫打赏