The carbon fiber thermal pad market has huge development potential and a large number of companies have entered the market in my country.

Carbon fiber thermal pads are one of the subcategories of thermal pads. They refer to thermal products with high thermal conductivity carbon fiber as the main filler. They are mainly used between heating components and radiators to improve the heat dissipation performance of electronic equipment. Compared with traditional thermally conductive silicone gaskets, carbon fiber thermally conductive gaskets have the advantages of light weight, low density, high modulus, extremely high thermal conductivity, good corrosion resistance, strong oxidation resistance, reusable, no silicone oil precipitation, etc., and are suitable for It is suitable for a variety of electronic equipment components with high precision requirements and high heat density.

High thermal conductivity mesophase pitch-based carbon fiber and silicone rubber resin are currently the main raw materials for the production of carbon fiber thermal pads. The thermal conductivity of high thermal conductivity mesophase pitch-based carbon fiber can reach more than 800W/m*K. Currently, my country’s Norco Carbon Materials has the large-scale production capacity of this product, and the second phase of the mesophase pitch-based carbon fiber project with an annual output of 1,200 tons is under accelerated construction. ; Silicone rubber resin has excellent softness, high temperature resistance, and flame retardancy. Its domestic production capacity will exceed 33 million tons in 2022. The gradual improvement of upstream raw material production capacity has created favorable conditions for the development of the domestic carbon fiber thermal pad industry.

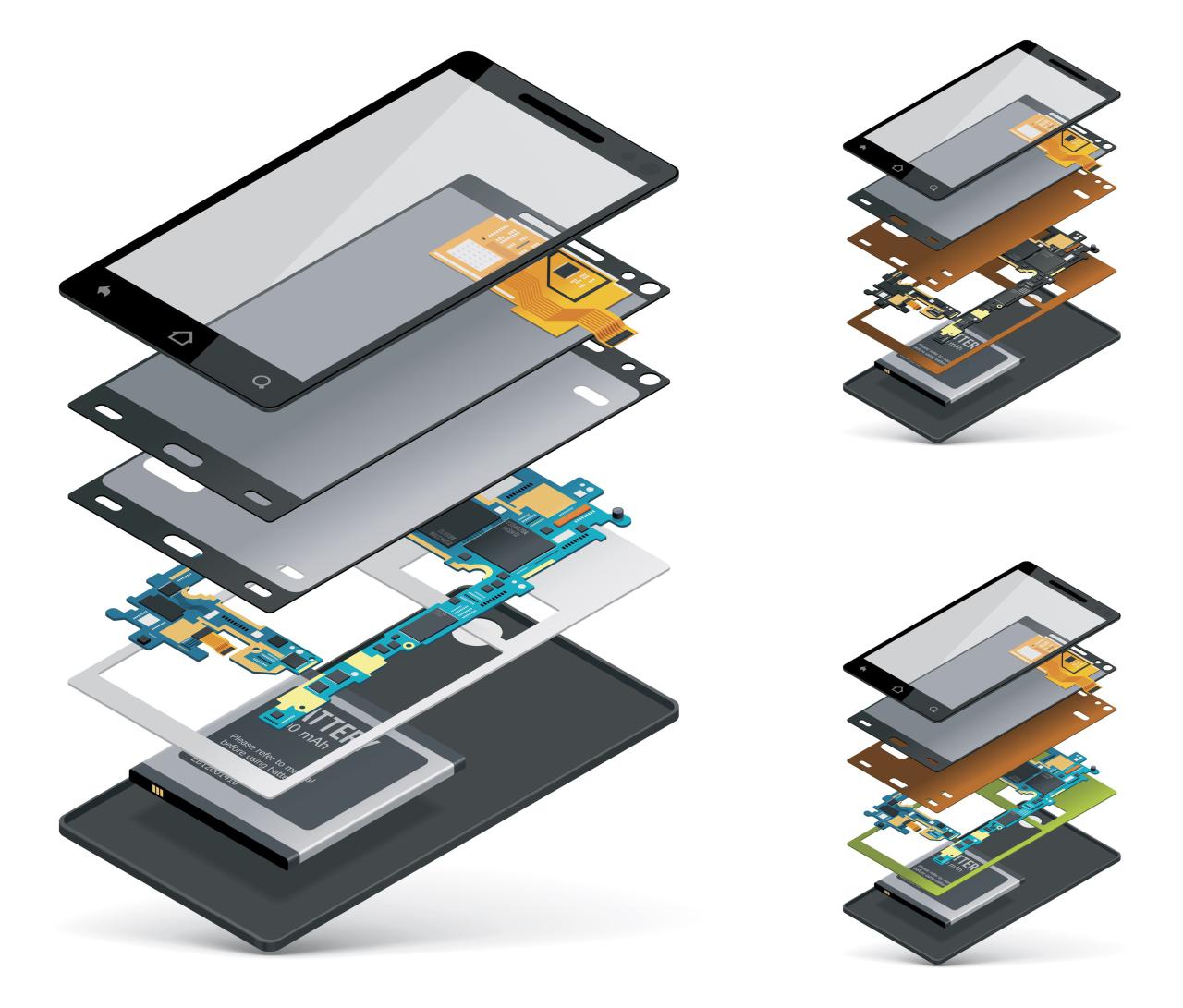

Carbon fiber thermal pads have a wide range of applications. The main application areas include automotive electronics, military electronics, communication electronics, consumer electronics, medical equipment, aerospace, wearable devices, etc. Among them, consumer electronics is the main application field of carbon fiber thermal pads. As domestic mobile phones are gradually developing towards high performance and high-end, the operating frequency of chips is gradually increasing, which in turn drives the continuous improvement of mobile phone thermal conductivity and cooling system requirements. Carbon fiber thermal pads have excellent performance and can meet the increasing heat dissipation requirements of mobile phones. They are currently used in some models of well-known mobile phone brands such as Samsung, VIVO, and OPPO.

According to 《 “2023-2028 Carbon Fiber Thermal Pad Industry Market In-depth Research and Investment Prospect Forecast Analysis Report” shows that in the future, under the background of the continuous highlighting of the advantages of carbon fiber thermal pads and the continuous upgrading of technology, its The penetration rate will continue to increase, and the industry shows great development potential. It is expected that by 2025, my country’s carbon fiber thermal pad market size is expected to approach 10 billion yuan.

Industrial analysts said that carbon fiber thermal pads are a new type of thermal pads with excellent performance and wide application Currently, with its advantages constantly highlighted and technology constantly upgraded, it is accelerating its replacement of traditional thermally conductive silicone gaskets, and its market penetration rate is continuously increasing. At present, most companies in my country have entered the carbon fiber thermal pad market, mainly including Beijing Zhongshi Weiye Technology, Tianjin Voltimo New Materials, Dongguan Shengyuan New Materials, Dongguan Shengen Electronic Technology, Shenzhen Laibid Technology, and Shenzhen Liqun MediaTek. Technology, Shenzhen Dubon Technology, Shenzhen Science and Technology Innovation Source, etc. The domestic substitution process in the domestic carbon fiber thermal pad market is continuing to accelerate, and the industry shows good development prospects.

微信扫一扫打赏

微信扫一扫打赏