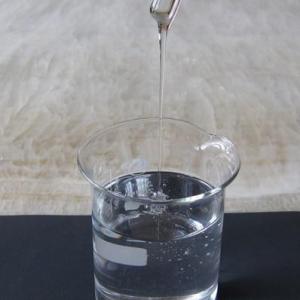

The difference between epoxy glue, polyurethane glue, and silica gel. Due to the lack of understanding of the three materials, when Chinese domestic companies choose insulation packaging materials, we often I don’t know how to choose. The materials of the three management systems have their respective advantages and disadvantages. Where are the differences? The following can be analyzed and explained through the development of bonding performance, heat resistance, insulation performance, flexibility (internal stress after curing, etc.), flame retardant performance, cost, processed product performance research, etc. Let us learn about epoxy glue and polyurethane together. The difference between glue and silica gel

Generally speaking, it has the following characteristics:

1. Epoxy adhesive has high hardness, high internal stress, strong adhesion, good electrical properties, excellent high temperature resistance and poor low temperature performance At present, the toughness and flexibility of epoxy adhesives have made rapid progress, which is worth noting. The defect is that the damage cannot be repaired, and shrinkage will occur after pouring

Epoxy curing and room temperature curing, the temperature resistance point of heating curing can generally exceed 100 degrees (depending on the curing agent and curing temperature, the temperature resistance is different); and The temperature resistance of room temperature curing is somewhat poor! It usually gets soft at 80 degrees! But it has an advantage that it is very confidential, especially after the cure is difficult! In electrical performance and weather resistance in general! Too cheap!

2. Polyurethane adhesives have the problems of moderate hardness, low internal stress, strong adhesion, good electrical properties, poor high temperature resistance, and excellent low temperature resistance. Polyurethane materials The electrical properties of the polyurethane adhesive are greatly reduced at high temperatures, and its process performance is poor, and it is easy to absorb moisture, which leads to good adhesion of the uncured polyurethane adhesive. It has different hardness, but the price is higher. In addition, the electrical properties are not very good. High, the electrical performance drops sharply, such as white carbon black glue! But some kinds of polyurethane will release harmful gas (substance) during curing, which will cause great harm to the environment and human body! The price is too high! However, the development of polyurethane is very rapid, and many defects are made up for by various modifications.

4. Low hardness, basically no internal stress, poor bonding strength, good electrical properties, excellent high and low temperature performance, and obvious advantages in weather resistance, but relatively expensive high. As for other aspects, it depends on the specific parameters of the material, including the above-mentioned properties, there are many modified materials, and various defects can be made up.

Silicone cures into an elastomer! High temperature resistance (- 60 °, 260 °), electrical performance and weather resistance are also very strong! For potted plants, if individual components are damaged, they can be repaired without trace! But one thing is that the adhesion is not good enough! The price is moderate!

微信扫一扫打赏

微信扫一扫打赏