The application fields of conductive ink continue to expand, and the industry has broad development prospects

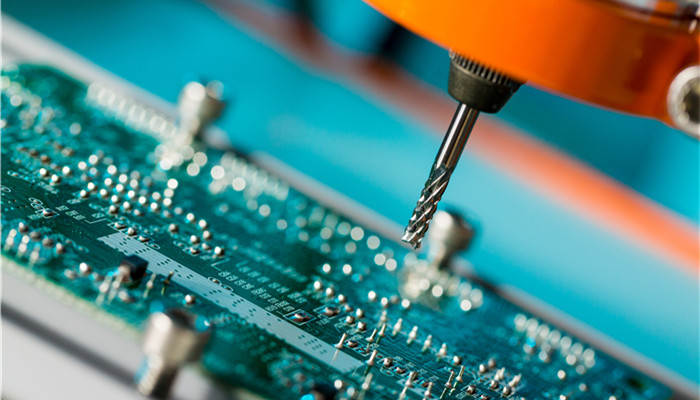

Conductive ink is a functional special ink, which is a conductive composite material composed of conductive fillers, connectors, solvents and additives. Conductive ink has excellent conductivity and can be used for screen printing, flexographic printing, letterpress printing, gravure printing, offset printing and other processes, and can be printed on plastics, glass, ceramics, cardboard and other substrates.

Conductive ink is an important raw material in the electronic printing process. It mainly plays the role of wires and resistors. It is widely used in printed circuits, thin film transistors, printed resistors, resistors, radio frequency antennas, printed electrodes and other fields. The terminal application involves automobiles. , biomedicine, electronics, display panels, energy, 5G, electricity and other scenarios. With the development of downstream industries and the advancement of emerging technologies, the market demand for conductive ink will continue to grow, and the industry has broad prospects for development.

According to the “2022-2026 Conductive Ink Industry In-depth Market Research and Investment Strategy Suggestions Report released by the Industrial Research Center, as With the development of the electronic information industry, the conductive ink market continues to expand. In 2021, the global conductive ink market will reach US$3.06 billion. It is expected that from 2022 to 2026, the global conductive ink market will grow at an average annual compound growth rate of about 3.8%.

There are many types of conductive inks. According to different raw materials, conductive inks can be divided into metal-based conductive inks, carbon-based conductive inks, and polymer-based conductive inks. Among them, metal-based conductive inks are the mainstream products in the market, and subdivided products include gold nano conductive inks, Silver nano conductive ink, copper nano conductive ink, etc. Carbon-based conductive inks can be divided into carbon nanotube conductive inks, graphene conductive inks, etc.

Graphene is a two-dimensional carbon nanomaterial with low sheet resistance, high electrical conductivity, and excellent thermal conductivity. Conductive ink made of graphene has better conductivity than traditional conductive ink and is compatible with screen printing. better. my country’s first graphene conductive ink production line was put into operation in 2015. With the advancement of graphene production technology, the graphene conductive ink market has strong development momentum. At present, companies related to graphene conductive ink include PPG, DuPont, Soken, Oriental Materials, etc.

As an indispensable raw material in electronic printing, conductive ink can realize the development of miniaturization, flexibility, thinness, functionality, and high performance of electronic products. In the era of the Internet of Everything, the application scenarios of conductive ink are expected to continue to expand, and the industry has broad prospects for development.

Industry analysts said that conductive ink has excellent conductivity and a wide range of application scenarios. As electronic products become smaller, thinner, and more flexible, Development, the market demand for conductive ink continues to grow, and the industry has good development prospects. There are many types of conductive inks, among which graphene conductive ink has excellent performance and is a research hotspot for domestic and foreign companies. In the future, with the advancement of production technology, the scale of the graphene conductive ink industry will continue to expand.

微信扫一扫打赏

微信扫一扫打赏