Air separation unit

On November 14, Guangxi Hengyi New Materials Co., Ltd. held the opening ceremony of the air separation plant construction general contracting project with an annual output of 1.2 million tons of caprolactam-polyamide industry integration and supporting engineering projects. At present, the project has fully entered the peak period of construction.

As the “front-end process” of the entire plant, the air separation unit has a gas supply scope covering all devices in the plant, requiring long-term reliable, stable and safe operation. It is reported that the air separation unit of the hydrogen-ammonia combined workshop of this project is planned to be constructed in two phases. The first phase is for 33,000 electric-driven air separation units. The production equipment of the air separation unit has the characteristics of high quality, large size and precision, the process flow is complex, and the equipment has the characteristics of flammability, high pressure and low temperature.

Hydrogen peroxide device

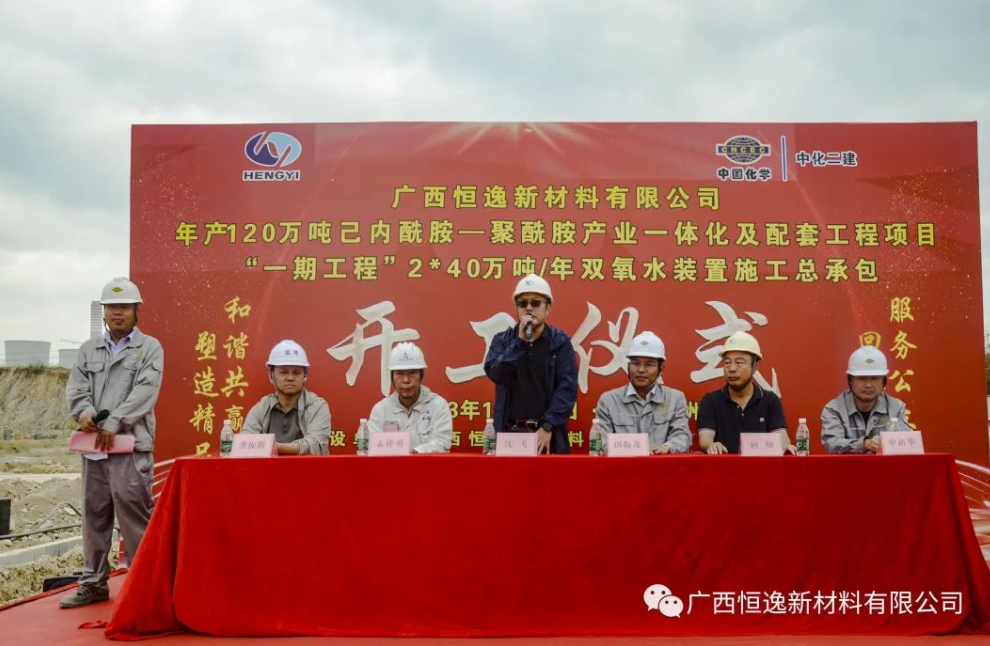

On November 12, Guangxi Hengyi New Materials Co., Ltd. officially started the civil construction and installation general contracting project of the hydrogen peroxide device with an annual output of 1.2 million tons of caprolactam-polyamide industry integration and supporting engineering projects.

The hydrogen peroxide device started this time is another important project of Guangxi Hengyi Company’s annual production of 1.2 million tons of caprolactam-polyamide industry integration and supporting engineering projects. The production capacity can reach 800,000 tons per year. It is a hydrogen peroxide hydration device independently developed by Hengyi. The first industrialized device for bed technology. Compared with traditional fixed bed technology, its construction is more complex and requires higher construction quality.

微信扫一扫打赏

微信扫一扫打赏