The gas separation membrane market continues to expand, and the competitiveness of local companies gradually increases

Gas separation membrane is an emerging technology. It refers to the process of enriching and separating gas mixtures on both sides of the polymer membrane by utilizing the differences in permeability and selectivity of different types of gas molecules in the polymer membrane under a certain pressure. Gas separation membranes were first successfully developed by Monsanto Company in the United States in 1979. The technology was widely used to recover hydrogen and ammonia in the purge gas of synthetic ammonia. In recent years, the commercialization process of gas separation membranes has been accelerating and has been widely used in many fields.

According to the “2022 Global and China Gas Separation Membrane Industry In-Depth Research Report released by the Industrial Research Center, compared with traditional polymer membranes In comparison, the gas separation membrane permeability and selectivity have been improved, and the overall performance is better. Driven by application demands, my country’s gas separation membranes have gained broad market space. In 2021, my country’s gas separation membrane market will reach 25.95 billion yuan, a year-on-year increase of 13.6%.

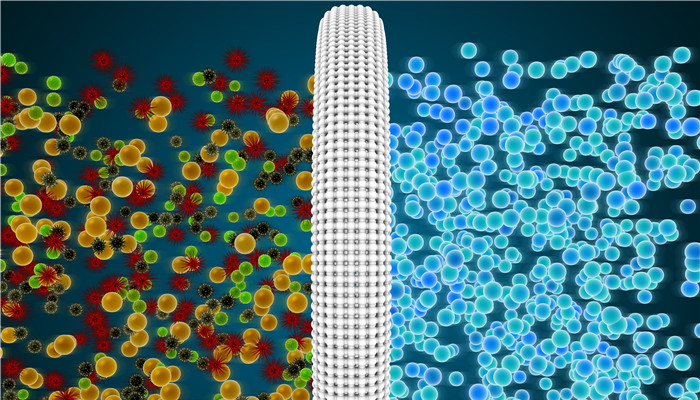

Gas separation membranes are composed of inorganic materials, organic-inorganic integrated materials, and polymer materials. Inorganic materials include molecular sieve membranes, metal membranes, alloy membranes and ceramic membranes, etc., which have the advantages of good chemical stability and simple preparation; organic-inorganic composite materials include molecular sieve-filled organic polymer membranes, etc., which have the advantages of corrosion resistance and high temperature resistance; Polymer materials include rubber membranes, glass membranes, polycarbonate (PC), cellulose acetate (CA), polyimide (PI), etc., which are the main materials for gas separation membranes currently used on a large scale.

Gas separation membranes are mainly used in biological research, medical care, environmental protection, transportation, petrochemical industry and other fields. Among them, petrochemical industry is the largest demand end for gas separation membranes. In the petrochemical industry, gas separation membranes were first used for hydrogen recovery in petrochemical plants. With continuous breakthroughs and innovations in production R&D technology, gas separation membranes are gradually playing an important role in carbon dioxide recovery and utilization, natural gas dehumidification, recovery and utilization of light hydrocarbons in oil fields, and synthesis gas control and regulation.

In terms of market competition, well-known overseas gas separation membrane companies include Dow Chemical of the United States, UBE Kosan of Japan, Environics of the United States, Monsanto of the United States, etc. my country’s local enterprises have long been committed to improving the production and research and development capabilities of gas separation membranes. As early as the 1980s, Dalian Institute of Chemical Physics already had gas separation membrane application technology. At present, my country’s leading gas separation membrane companies include Dalian Ouke Membrane, Zhongkai Chemical, Dalian Tianbang, etc.

Industry analysts said that gas separation membranes, as a subdivision of materials science, after years of development and technology accumulation, the technical level of my country’s leading enterprises has improved. And the continuous improvement of research and development capabilities has driven the growing demand for gas separation membrane applications. With the gradual implementation of national environmental protection policies, gas separation membranes have gained broad market space in industrial exhaust emission treatment, and the development prospects of the industry will continue to improve.

微信扫一扫打赏

微信扫一扫打赏