BASF is expanding its proven Ultrasim® simulation portfolio for plastics applications: From now on, the simulation capabilities will also cover the manufacturing process of granular foam components. Customers can use Ultrasim® to speed up the development process of their components and save costs.

From bicycle tires to shoe soles: Simulating components made withInfinergy®

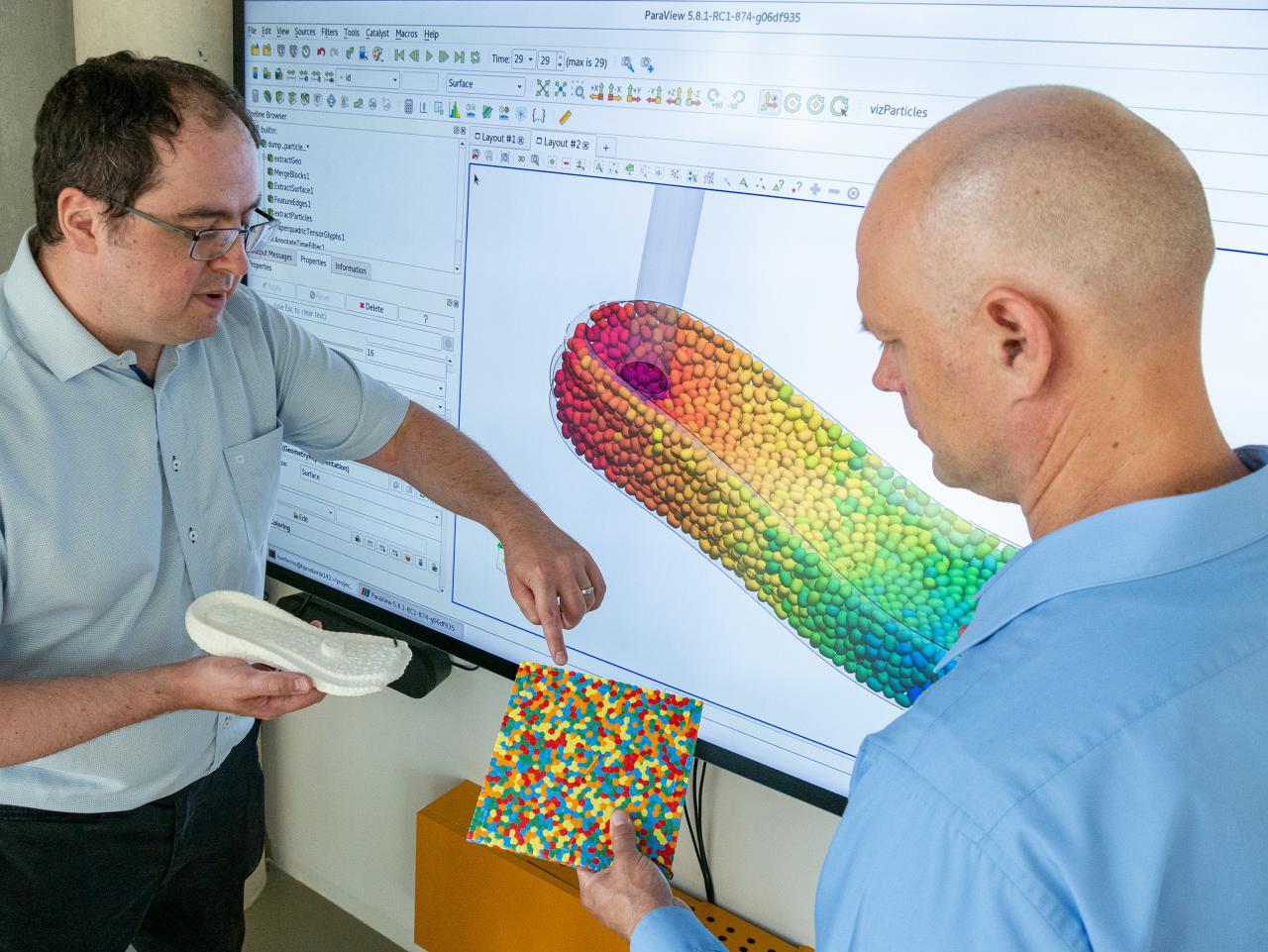

The new Ultrasim® solution was developed for Infinergy®, an expanded thermoplastic polyurethane (E-TPU) that is used in a wide range of applications. Achim, Team Leader, Ultrasim®Core

Besser said: “Whether it’s for bicycle tires or shoe soles, granular foams such as Infinergy® are typically filled with air. This means that the particles are distributed in the mold with the help of compressed air. However, how the manufacturing process was discovered already during the component development phase What about potential problems? This is where Ultrasim® can help from now on.”

New simulation capabilities cover the entire manufacturing process of granular foam parts, simulation engineer Moritz

Höfert says: “Which path does the air take to enter the mold and exit again? Should the customer change the venting of the mold or the position and amount of filler to avoid air pockets? Is gravity being optimally utilized? How does closing the mold change the particle filling? Finally, how does the finished part perform under load?”

Martin, Senior Manager, Global Technology Development

Vallo said: “If our customers know the answers to these questions, they can fully exploit the potential of granular foam. For example, in the midsole of a shoe, the filler affects the density and stiffness of the sole. Ultrasim® simulations can optimize these two parameters. , and harness the full potential of Infinergy®.”

The new application was originally developed for E-TPU Infinergy®. Simulation expertise can be transferred to other granular foams, enabling an assessment of which granular foam is best suited for the planned part.

微信扫一扫打赏

微信扫一扫打赏