1. Oily acrylic resin (oily solid acrylic resin/oily liquid acrylic resin): A Oily liquid acrylic resin: refers to acrylic acid with a resin solid content of 30-80% Resin, this type of resin is an acrylic resin containing organic solvents formed by emulsion polymerization. When the content is more than 60%, it is called: high solid acrylic resin. This type of resin has low viscosity and low VOC content. ! When the solid content is around 50%, there are thermoplastic and thermosetting acrylic resins, which are the single-component and two-component applications mentioned above in our coating industry.

1. One-component paint is generally called a self-drying paint, which is a paint that uses thermoplastic acrylic resin as a film-forming substance.

2. When thermosetting acrylic resin is generally paired with amino resin, due to the reaction between the amino and hydroxyl groups between the two, it should be considered a two-component paint. It is commonly referred to as baking paint, which is generally used on metal. The baking temperature is generally above 100 degrees. This type of application is the oldest and earliest, and can often be seen in life.

3. Thermosetting acrylic resin is generally combined with a curing agent (usually isocyanate), and then other materials are added to become what is called a two-component coating in the coatings industry. It already has a main agent (acrylic resin), a curing agent, and a diluent. This kind of performance is more stable than that of thermoplastic acrylic resin, and its performance is also superior.

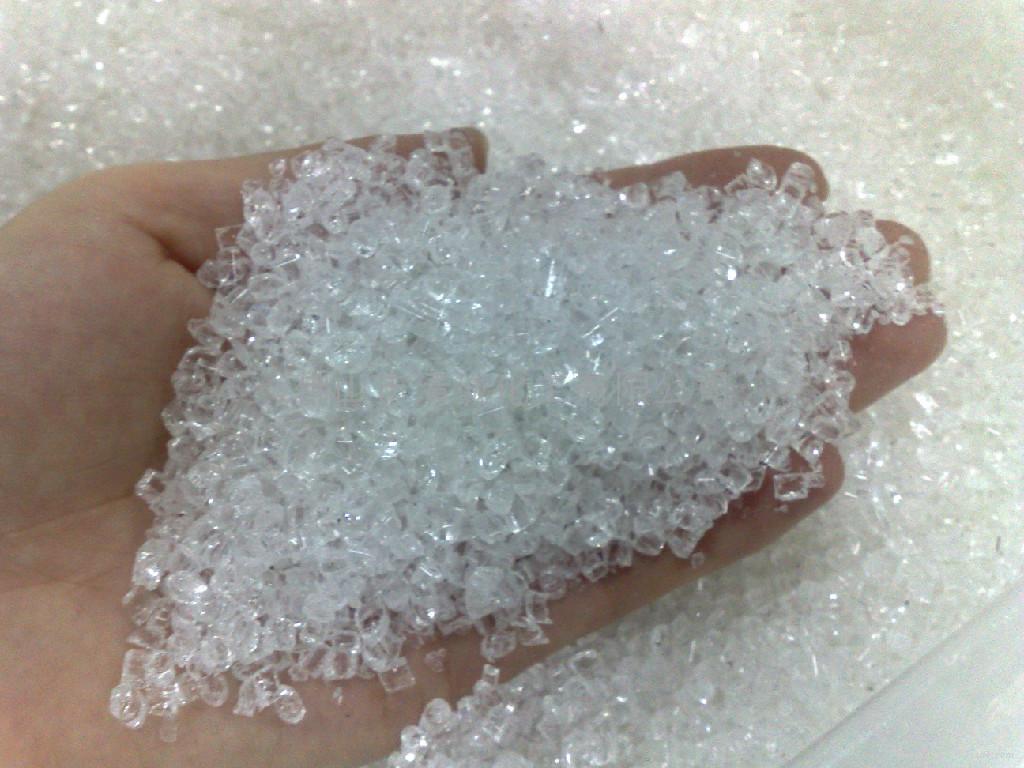

B oily solid acrylic resin: (ordinary oily thermoplastic solid acrylic resin/special functional oily solid acrylic resin) Solid acrylic resin, currently the main one on the market is thermoplastic solid Mainly acrylic resin! This type of thermoplastic solid acrylic resin is also called solvent-based solid acrylic resin. Because they are generally soluble in solvents, such as benzene, esters, ketones, chlorides, ethers, alcohols, etc.!

The solubility will be different depending on the synthesis! The most commonly used grades of solid acrylic resin are generally made of MMA and BMA, which is methacrylic acid. ester, butyl methacrylate, etc. Because the glass transition temperature of the monomer synthesized from methyl-containing acrylate is relatively high! The performance of the resin is generally determined by the performance of the monomer’s formula raw materials in the production process!

When the synthesized monomers are all made of MMA! Its hardness will be very high! It is also what we often call acrylic and plexiglass! But this kind of Resin is not easy to use as a coating! It is generally used on plastic sheets! Ordinary solid acrylic resin is generally composed of MMA and BMA in different proportions into the formula to synthesize solid acrylic resin with different index properties! The usual glass transition temperature is 50-100 Between! The softening point is also between 150-200 degrees! The molecular weight depends on other synthetic additives! This type of resin is the most common in application. Liquid thermoplastic acrylic resin is used! It is generally used! It’s just that some of them can’t achieve the effect of liquid performance.

Acrylic resin can be used in a wide range of applications, such as:

1. Usage of ordinary oily thermoplastic solid acrylic resin:

Paper and wood coatings: Generally, the glass transition temperature is 50-80 degrees, the softening point is around 160, and the molecular weight is 35,000-80,000. Many differences in raw materials and monomers determine its application! For example, the glass transition temperature. Generally speaking, the higher the TG, the higher the hardness, and the easier the finished product is to be brittle; the lower the TG, the more flexible it will be. The better, and the finished product will be easier to apply to materials with soft substrates. Generally speaking, the softening point in self-drying coatings is sufficient to withstand normal temperatures, but some applications that require high temperature resistance cannot meet the requirements! Molecular weight mainly affects the viscosity of the product, but it is not the main reason for the viscosity. But generally speaking, it affects the level of viscosity. Generally speaking, the higher the molecular weight, the higher the viscosity. When the viscosity is high, the speed at which the resin can be dissolved is slower, and the soluble solid content is lower, so the viscosity During application, it affects the fullness, gloss and solid content of the paint!

2. Special functional oily solid acrylic resin uses:

For example, high alcohol resistance and high wear resistance: electronic and electrical products, internationally speaking, generally require alcohol resistance, because the outside of electrical appliances are made of plastic and hard Therefore, it requires high hardness and good wear resistance! Therefore, ordinary solid acrylic resin cannot be used on it at this time! But it has good alcohol resistance, usually 500 grams of alcohol, and the test wipe back and forth is not less than 50 Time! Therefore, acrylic resin must be resistant to alcohol.�Product! In terms of product performance, it generally depends on the solubility index of solid acrylic resin. If a solid acrylic resin has poorer solubility and is more insoluble, it will generally have alcohol resistance, but it is not the decisive factor.

For example, high adhesion: when applied to substrates that are difficult to adhere to, such as PC, PP, hard PE, etc., these substrates are difficult to handle Products with adhesion problems sometimes have other requirements due to their application in different places. When PC is used in eyeglass frames or frames, it is required to be polished, high-gloss, and resistant to bending! And PP substrate is also more difficult. Treated substrates on the market are now often treated with PP adhesion water before painting. However, there are also acrylic resins that can be directly painted to solve the adhesion problem. However, this type of resin It is a modified resin! Hard PE also has acrylic resin that can solve adhesion, but it is only limited to hard PE substrates, and this kind of acrylic resin must be modified before it can be used. Because the solubility parameter of the modified acrylic resin is closer to that of PP or hard PE, its effect can be exerted.

For example, high environmental protection requirements: when it is applied to some substrates used in food, then the coating material is required to be environmentally friendly, that is Environmentally friendly paints are used. At this time, apart from the water-based solid acrylic resins that can be used, most of the market still uses alcohol-soluble resins, and alcohol-soluble acrylic resins are generally solution-based in the market! Alcohol-soluble solid acrylic resin is more difficult to produce. It has a high molecular weight and high viscosity, so its application is not as wide as the ordinary type. It is soluble in solvent oil, ethanol, high alcohol, etc.!

微信扫一扫打赏

微信扫一扫打赏