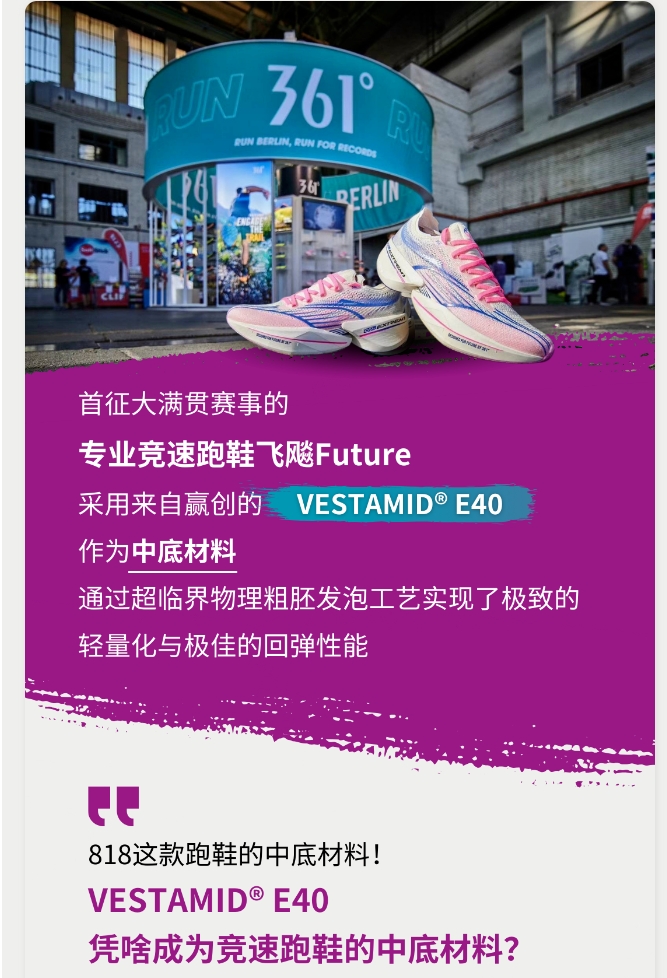

On September 24, the Berlin Marathon officially kicked off. This appearance at the Berlin Marathon is the first time that Feibiao Future, a professional elite marathon racing shoe from 361°, competes in a Grand Slam event. For Evonik, it is another strong alliance between a specialty chemical raw material company and a local Chinese brand. The 361° team not only officially debuted this shoe in international competitions, but was also invited to visit Evonik for exchanges.

361° formed a “Track Three” team overseas with nearly a hundred people to participate in the competition, and sent its own brand spokesperson Li Zicheng, running spokesperson Guan Yousheng, and Track Three elite athlete TIRUNEH WORKNEH

TESFA, LEMA ALEMAYEHU MEKONEN, WOLDEGIORGIS ABAYNEH

AYELE competes and achieves great results on this “world’s fastest track”. On the road to faster, higher, stronger, exploring and breaking through limits, people never stop. In a fiercely contested competition, LEMA

ALEMAYEHU MEKONEN ran a good time of 2 hours, 12 minutes and 24 seconds; in terms of domestic players, Li Zicheng, who returned to the competition after a long absence, showed good form with a time of 2 hours, 15 minutes and 40 seconds.

The Feibiao Future professional carbon plate racing running shoes worn by the athletes competed in a Grand Slam event for the first time. The midsole material of the running shoes is VESTAMID® E40 from Evonik.

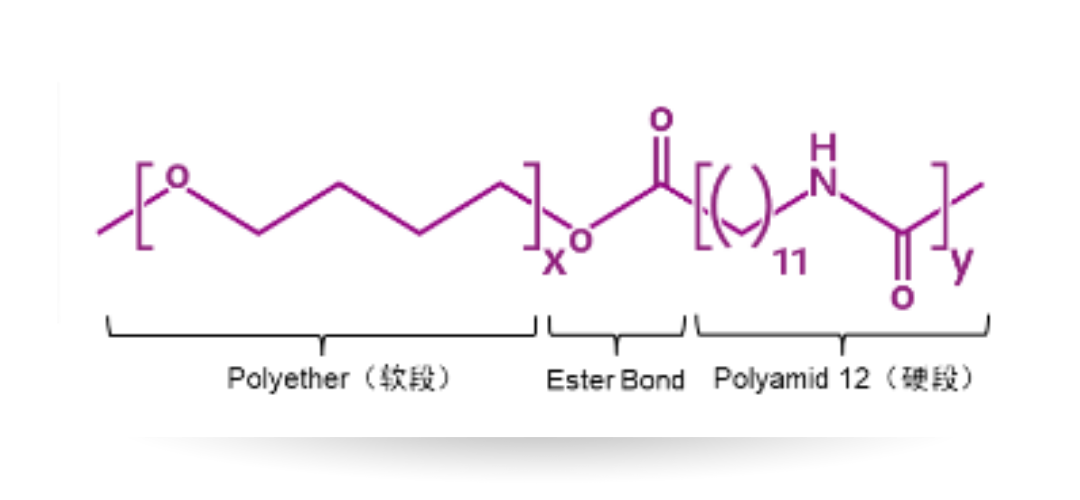

First of all, if you look directly at the molecular formula of this material, it is as enigmatic as many chemicals:

However, to put it simply, as one of Evonik’s star products, the industry generally calls it PEBA:

In 1979, Evonik officially launched the thermoplastic elastomer material PEBA under the brand name VESTAMID® E. Since its launch, VESTAMID® E

PEBA elastomer stands out for its excellent low-temperature impact resistance, chemical resistance and good resilience, and has quickly become the material of choice for high-performance sporting goods such as sports shoes, ski boots and mountaineering boots.

VESTAMID® E40 as Evonik VESTAMID® E

A member of PEBA’s product matrix, it has always been favored by high-end sports shoe midsole materials, and with the continuous improvement of technology, it brings a better wearing experience and better competition results.

VESTAMID E

The PEBA family has many different brands of products that can meet the diverse needs of customers and consumers in different usage scenarios. On the one hand, it is suitable for a variety of different supercritical foaming processes, and the lowest density after foaming can be less than 0.1g/cm3. At the same time, it can also provide users with sufficient cushioning and support to avoid sports injuries.

In terms of sustainability, Evonik has also launched eCO-level renewable raw material products in the VESTAMID® series. Evonik VESTAMID® eCO

E40 uses waste tires as sustainable raw materials. In the value chain, this recyclable raw material replaces 50% of fossil raw materials. VESTAMID® eCO

E40 uses green energy in the electricity production process, using 100% waste biomethane to generate electricity and steam. The sustainable manufacturing process used by Evonik does not change the characteristics of the product, so the material can directly replace the customer’s existing product and can be used directly in the customer’s existing production process without any adjustments. At the same time, VESTAMID®

eCO E40 can reduce carbon dioxide emissions by up to 40%.

微信扫一扫打赏

微信扫一扫打赏