Overview[1]

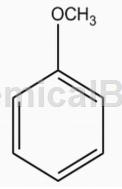

Anisole is a colorless liquid with an aromatic odor. Anisole is widely used in the preparation of many floral flavors, especially gardenia, lilac, and sunflower flavors. It is also used as an antioxidant in beer, and is also a raw material for the synthesis of ethylene polymer UV stabilizers and enteric insecticides. It is also commonly used as a solvent in organic chemistry.

Currently, phenol and dipotassium sulfate are used as raw materials in production, and the reaction is carried out under alkaline conditions to produce anisole. Because dimethyl sulfate is a highly toxic substance, it has a strong irritating effect on the eyes and upper respiratory tract, and a strong corrosive effect on the skin. It can cause conjunctival congestion, edema, corneal epithelial shedding, partial necrosis of tracheal and bronchial epithelial cells, and puncture leading to Mediastinal or subcutaneous emphysema can also damage the liver, kidneys and myocardium. Skin contact can cause burns, blisters and deep necrosis. It is also potentially carcinogenic and highly corrosive.

Preparation[2-3]

Using sodium phenolate and dipotassium sulfate as raw materials is currently the main method for producing anisole. The specific steps are as follows: add phenol to 13% sodium hydroxide solution, stir until completely dissolved, and cool to 10°C Then, slowly add the theoretical amount of dimethyl sulfate under rapid stirring, control the reaction temperature not to exceed 30°C, and after the addition is completed, heat up and reflux for 18 hours. After the reaction is completed, cool and let stand for layering. Take the upper organic phase, wash it with salt water, let it stand for layering and discard the water layer. The oil layer is dried and dehydrated with anhydrous calcium chloride, and then distilled under reduced pressure to obtain the finished product. Since the main raw material dimethyl sulfate is highly toxic, its effect is similar to mustard gas, and its acute toxicity is similar to phosgene, which is 15 times greater than chlorine. It has a strong irritating effect on the eyes and upper respiratory tract, and a strong corrosive effect on the skin. It can cause conjunctival congestion, edema, corneal epithelial shedding, partial necrosis of tracheal and bronchial epithelial cells, and puncture leading to mediastinal or subcutaneous emphysema. In addition, it can also damage the Liver, kidney and myocardium, etc., skin contact can cause burns, blisters and deep necrosis. It is potentially carcinogenic and highly corrosive.

U.S. invention patent US2490842 discloses a method for preparing anisole, which uses an excess of sodium phenolate to fully react with dimethyl sulfate, thereby reducing environmental pollution and harm to the human body caused by dimethyl sulfate. The price of phenol in my country is higher than that of dimethyl sulfate, and excessive phenol makes wastewater treatment difficult. Therefore, Zhang Shengwan and others from Shanxi University applied for a Chinese invention patent (94101265.4) “Preparation Method of Anisole” in order to solve the above problems. , which discloses a method for preparing anisole. The characteristics of the invention are: using excess dimethyl sulfate and sodium phenolate to fully react to convert it into anisole, and using sodium hydroxide to convert the excess dimethyl sulfate into sulfuric acid. sodium.

The specific operation steps are as follows: excess 20-25% dimethyl sulfate and sodium phenolate solution prepared in equal moles from 20% (weight) sodium hydroxide and phenol are reacted at 10-30°C for 1 hour, 40 ℃ for half an hour, react at reflux temperature for half an hour, and then azeotropically distill out anisole. During the distillation process, the steamed water part is returned to the reactor. The anisole obtained by azeotropic distillation is close to 90% of the theoretical yield. When, add sodium hydroxide solution with a concentration of 20% (weight) in the reactor, continue the reaction, distill for half an hour to 1 hour, so that all the anisole generated by the reaction is distilled out, and then the crude anisole product is dried Re-steam. In order to solve the problem of dimethyl sulfate pollution, this invention patent adds an excess of 25-30% dimethyl sulfate to the reaction system. The excess dimethyl sulfate is then reacted with sodium hydroxide to reduce the damage caused by dimethyl sulfate to the human body. In terms of environmental pollution, this makes sense, but in terms of overall cost, it is uneconomical, and excessive dimethyl sulfate requires the consumption of a large amount of sodium hydroxide and will also produce more sulfuric acid. High-concentration organic wastewater containing sodium will also put greater pressure on waste treatment. Moreover, the invention patent does not solve the problem of high-concentration organic wastewater containing sodium sulfate.

Main reference materials

[1] Tong Bin, Dai Rongji, Fu Ruonong, Gu Junling, Deng Yulin, & Zhang Baoyan. (2003).Synthesis and characterization of ��molecular liquid crystals. Journal of Minzu University of China (Natural Science Edition), 12(2), 111-116.

[2] Song Xijin, & Wang Changshen. . New process for synthesizing anisole. Fine Chemicals (1), 44-46.

[3] Zhang Luan. (2013). Research on removal of trace water from anisole by adsorption method. (Doctoral dissertation, Tianjin University).

微信扫一扫打赏

微信扫一扫打赏