On April 10, Levima Xinke released the “Prospectus for Issuing A Shares to Specific Targets (Draft Application)” and planned to issue no more than 267,113,600 shares to no more than 35 specific investors.

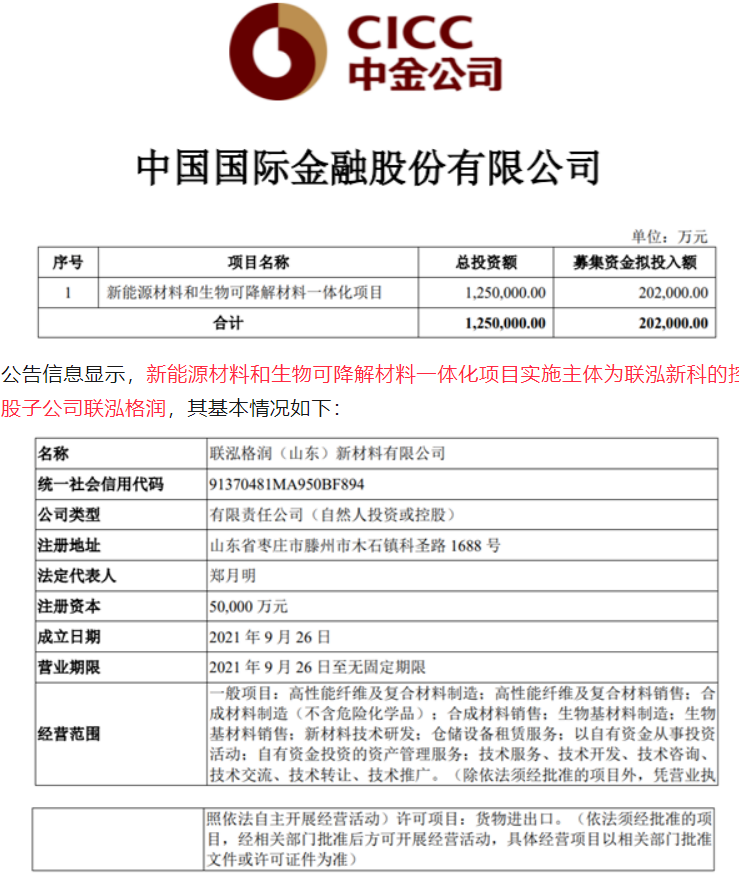

The total amount of shares (including the principal amount) and the total raised funds shall not exceed 2.020 million yuan (including the principal amount). The net raised funds after deducting the issuance expenses are planned to be invested in new energy materials and biodegradable material integration projects.

The construction site of the integrated new energy materials and biodegradable materials project is located in Lunan High-Tech Chemical Park, Tengzhou City, Shandong Province. The construction content includes 1.3 million tons/year DMTO

Unit (methanol to olefin unit), 200,000 tons/year EVA unit, 300,000 tons/year PO unit, 50,000 tons/year PPC unit, supporting public works and auxiliary production facilities, etc. The total investment amount of the project is

12,500,000,000 yuan, and the amount of raised funds planned to be used is 2,020,000,000 yuan. This issuance of A to specific targets

Before the funds raised for the shares are in place, the company can first invest with self-raised funds based on the actual situation of the investment project with the raised funds, and replace them after the raised funds are in place. If the actual amount of raised funds (after deducting issuance costs) is lower than the amount of raised funds intended to be used by the project, the shortfall in raised funds will be settled by the company with its own funds or through other financing methods.

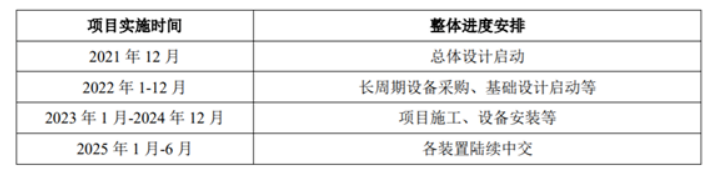

The project construction period is approximately 3 years. The project implementation time is as follows:

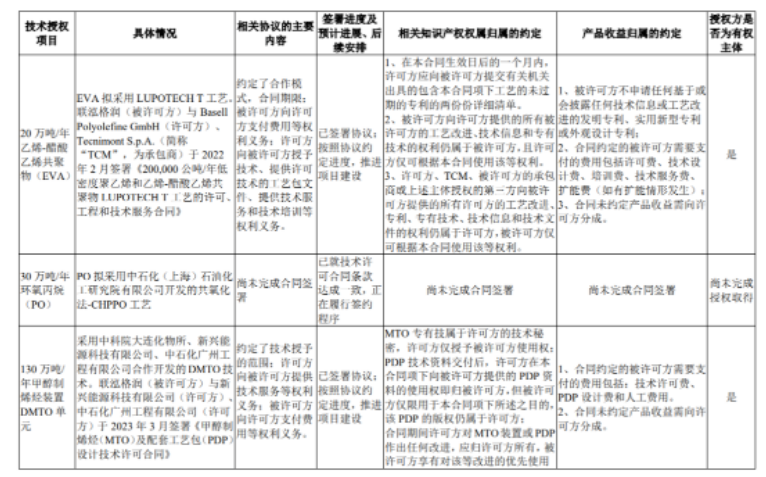

200,000 tons/year EVA project adopts Lyondell Basell

High-pressure tubular process technology mainly produces high value-added photovoltaic film material products. After the project is implemented, the company will have both the world’s leading Lyondell Basell tubular process and Exxon Mobil

The kettle method is conducive to improving the flexibility of production operations and promoting the development of new products.

PO project adopts the world’s leading co-oxidation CHPPO process technology. Compared with other PO

The production technology has the advantages of high product yield, less by-products, low unit consumption and carbon emissions.

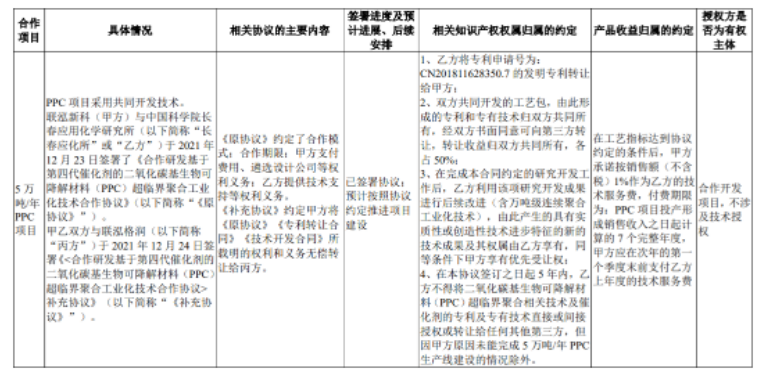

PPC

The project adopts a new generation of supercritical polymerization technology jointly developed with the Changchun Institute of Applied Chemistry of the Chinese Academy of Sciences. It has the characteristics of high carbon dioxide mass proportion, high single-pass conversion rate, short reaction time, low production energy consumption, few by-products, and high-quality products. It has the characteristics of high molecular weight and leading technology in the industry.

At present, the project has obtained the “Shandong Province Construction Project Registration Certificate” issued by the Shandong Province Investment Project Online Approval and Supervision Platform, and the “About Levima Green (Shandong) New Materials Co., Ltd. New Energy Materials and Biorecyclables” issued by the Zaozhuang Ecological Environment Bureau Approval of the Environmental Impact Report of the Integrated Project of Degradable Materials”, and “Review Opinions on the Energy Saving Report of the Integrated Project of New Energy Materials and Biodegradable Materials of Levima Green (Shandong) New Materials Co., Ltd. issued by the Development and Reform Commission of Shandong Province 》.

As a supplier of new material products and solutions, Levima New Technology focuses on the development direction of new materials, focusing on the fields of new energy materials and biodegradable materials, and strives to create a leading industrial cluster in several subdivisions of new materials.

In terms of new energy materials, Levima is the leading domestic manufacturer of EVA photovoltaic film materials and is building a 3,000 tons/year vinylene carbonate (VC) project and 2

10,000 tons/year ultra-high molecular weight polyethylene lithium battery separator material project has been completed for 10 years

The construction of a 10,000 tons/year lithium battery material-carbonate combined device project is in the production preparation stage; in the future, it will form a multi-category new energy material industry layout such as photovoltaic film materials, electrolyte solvents and additives, and lithium battery separator materials.

Relying on its unique industrial layout and product structure, outstanding R&D and innovation capabilities and other advantages, Levima New Technology is the first in China to develop EVA

The product quality of photovoltaic film materials ranks among the advanced levels in the industry at home and abroad, and it has accumulated good reputation and market influence. In 2022, the company carried out technological upgrades and capacity expansion transformation of the EVA device.

Production increased further. After the 200,000 tons/year EVA project is put into operation, Levima Newco’s EVA production capacity will reach approximately 350,000 tons/year. At the same time, Levima is advancing the construction of a 90,000-ton/year VA unit, which will basically meet the

With the demand for raw materials supporting EVA devices, Levima Xinco’s industrial chain will be more complete, further enhancing Levima Xinco’s competitiveness.

In terms of biodegradable materials, Levima Newco has independently developed PLA full industry chain technology, and its holding subsidiary Academy of Sciences Biotech is building a 100,000 tons/year lactic acid, 4

The 10,000 tons/year polylactic acid (PLA) project will be completed and put into production by the end of 2023. PPC

The project adopts industry-leading technology jointly developed by Levima Newco and the Changchun Institute of Applied Chemistry, Chinese Academy of Sciences. Once put into production, the project will further enrich the company’s biodegradable material categories, expand the product scale of the biodegradable materials segment, and enhance Levima Newco’s market position and Influence.

微信扫一扫打赏

微信扫一扫打赏