Overview[3]

Me-diethylbenzene and p-diethylbenzene are important chemical raw materials and intermediates. Desorbents can be prepared by polymerizing meta-diethylbenzene. In addition, with the increase in demand for polyester and pharmaceutical intermediates, the demand for m-diethylbenzene and p-diethylbenzene continues to expand.

Apply[1]

Meta-ethyl acetophenone is an important organic synthesis intermediate and is widely used in the synthesis of medicines, pesticides, dyes, flavors and fragrances, perfumes, etc. At present, the main preparation methods of m-ethyl acetophenone include Friedel-Crafts acylation method and m-diethylbenzene oxidation method. The m-diethylbenzene oxidation method is divided into chemical oxidation method and molecular oxygen oxidation method. Oxygen is cheap and easy to use. The method of producing m-ethyl acetophenone by directly oxidizing m-diethylbenzene with oxygen, which is a clean, pollution-free and atom-economical oxidant, has significant advantages over other methods.

In a three-necked flask, add 76.5g of m-diethylbenzene, 0.027g of cobalt chloride hexahydrate and 0.09g of pyridine, use a Dean-Stark water separator to remove water, introduce air at a flow rate of 200mL/min, and add air at 120 After reacting for 20 hours at ℃, the conversion rate of m-diethylbenzene was 82%, while the chromatographic yield of m-ethyl acetophenone was only 54%.

Preparation[1-2]

CN201710936347 is based on the separation of p-diethylbenzene from mixed diethylbenzene through adsorption. The content of diethylbenzene in the adsorption raffinate is relatively concentrated, and extractive distillation is performed to obtain metadiethylbenzene with a purity of more than 95%. Ethylbenzene. This method has a simple process and can obtain more than 95% m-diethylbenzene, which can increase the added value of the mixed diethylbenzene and the intermediate diethylbenzene and effectively utilize the m-diethylbenzene resources in the mixed diethylbenzene. The technical solution proposed by the present invention is to send the adsorption raffinate rich in meta-diethylbenzene obtained after adsorption separation of mixed diethylbenzene into an extractive distillation tower for extractive distillation. The top of the extractive distillation tower obtains meta-diethylbenzene. The purity of diethylbenzene and m-diethylbenzene is greater than 95%. Mixed diethylbenzene and solvent are obtained at the bottom of the tower. The mixed diethylbenzene and solvent are separated by the solvent recovery tower to obtain the solvent and mixed diethylbenzene. The solvent can be returned to the extraction essence. The distillation column is reused, and the mixed diethylbenzene can be used as the raw material for mixed divinylbenzene.

Compared with the existing technology, the advantage of the present invention is that it can separate more than 95% m-diethylbenzene from the mixed diethylbenzene adsorption raffinate by distillation, and the yield of m-diethylbenzene is less than 1%. Less than 90%; at the same time, the extraction agent is recycled, no environmentally harmful substances are produced, and the effective utilization of the intermediate diethylbenzene resources in the mixed diethylbenzene is achieved.

CN201510670288 provides a method for extracting mixed diethylbenzene, intermediate diethylbenzene and p-diethylbenzene by three consecutive extraction distillations. The method includes the following steps:

⑴ First, sulfolane is used as the extraction agent, and the raw material mixed with diethylbenzene enters the first extractive distillation tower for the first extractive distillation separation; after the mixed diethylbenzene undergoes the first extractive distillation separation, the first extractant The m-diethylbenzene enriched liquid with m-diethylbenzene content ≥75.0wt% is obtained at the top of the distillation tower, and the mixed liquid containing the extractant sulfolane is extracted from the bottom of the first extractive distillation tower;

(2) After the mixed liquid containing the extracting agent sulfolane obtained at the bottom of the first extraction and rectification tower is separated by the first solvent recovery tower, the extracting agent sulfolane obtained at the bottom of the first solvent recovery tower is recycled; the first solvent recovery The p-diethylbenzene enriched liquid is obtained at the top of the tower;

(3) Using sulfolane as the extractant, the m-diethylbenzene enriched liquid obtained from the top of the first extractive distillation tower enters the second extractive distillation tower for the second extractive distillation separation. The second extractive distillation Meta-xylene with a content of ≥95.0wt% is obtained at the top of the tower; the extraction agent sulfolane with a content of ≥96.0wt% is obtained at the bottom of the second extractive distillation tower;

(4) The extraction agent sulfolane with a content of ≥96.0wt% obtained at the bottom of the second extractive distillation tower is processed by the second solvent recovery tower, and the extraction agent sulfolane obtained at the bottom of the second solvent recovery tower is recycled. The second solvent Mixed diethylbenzene is obtained at the top of the recovery tower;

(5) Using glycerin as the extractant, the p-diethylbenzene enriched liquid obtained from the top of the first solvent recovery tower enters the third extractive distillation tower for the third extractive distillation separation. The third extractive distillation tower Para-diethylbenzene with a content of ≥95.0wt% is obtained at the top; the extraction agent glycerin with a content of ≥96.0wt% is obtained at the bottom of the third extractive distillation tower;

(6) After the extraction agent glycerin with a content of ≥96.0wt% obtained at the bottom of the third extractive distillation tower is separated by the third solvent recovery tower, the extraction agent glycerol obtained from the bottom of the third solvent recovery tower is recycled and used. A mixture of diethylbenzene and triethylbenzene is obtained at the top of the recovery tower.

The extraction and separation process of the present invention includes three times of extractive distillation and three times of solvent recovery. The separation process is simple. The content of separated m-diethylbenzene reaches more than 95.0wt%, the yield is 91%, and the content of p-diethylbenzene is 95.0 wt% or more, the yield is 89.99%.

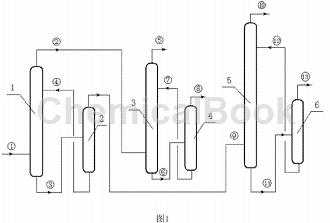

Figure 1 is a process flow chart for three consecutive extractive distillations combined with extraction of mixed diethylbenzene, intermediate diethylbenzene and p-diethylbenzene.

Main reference materials

[1] [China invention, China invention authorization] CN201010103446.9 Method for preparing m-ethyl acetophenone by biomimetic catalytic oxygen oxidation of m-diethylbenzene

[2] [Invented in China] CN201710936347.0 A method for separating meta-diethylbenzene

[3] [China invention, China invention authorization] CN201510670288.8 A method for extracting diethylbenzene, intermediate diethylbenzene and p-diethylbenzene by three consecutive extractive distillations

微信扫一扫打赏

微信扫一扫打赏