Background and overview[1]

Light yellow oily liquid with a nitrobenzene-like odor. The relative density is 1.1571, the melting point is 16°C, and the boiling point is 230~231°C. Almost insoluble in water, soluble in ethanol, ether, chloroform and benzene. Can evaporate with water vapor. It is obtained by nitrating toluene with mixed acid below 50℃, then fractionating and refining it. Depending on the reaction conditions and catalysts, toluene nitration can produce different products, such as o-nitrotoluene, p-nitrotoluene, m-nitrotoluene, 2,4-dinitrotoluene and 2,4,6-trinitrile. Toluene, etc. Nitrotoluene and dinitrotoluene are important pharmaceutical, dye and pesticide intermediates. Under general reaction conditions, among the three intermediates of nitrotoluene, there are more ortho products than para products, and para products are much more than meta products. At present, the domestic market has a large demand for ortho- and para-nitrotoluene, so the topic of positioning nitrification of toluene is being studied at home and abroad, hoping that the yields of ortho- and para-positions can be increased as much as possible. However, there is currently no ideal result, and a certain amount of m-nitrotoluene is inevitable. Since the development and utilization of m-nitrotoluene has not kept up in time, toluene nitration by-products can only be sold at low prices or have a large inventory backlog, resulting in a huge consumption of chemical resources.

Preparation[1]

It is obtained by nitrating toluene with mixed acid below 50℃, then fractionating and refining it.

Purpose[2-3]

The synthesis of downstream products from m-nitrotoluene mainly involves the oxidation, reduction and chlorination reactions of the two groups on the benzene ring.

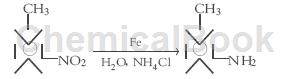

1) Synthesis of m-toluidine: m-toluidine is an intermediate of reactive yellow X-R and cationic violet 2RL. Production method: Prepared by reduction of m-nitrotoluene with iron powder [1], the reaction formula is:

The general yield reaches 98%. Currently, the relatively clean synthesis processes are catalytic hydrogenation reduction and electrolytic reduction.

2) Synthesis of m-cresol

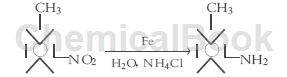

M-cresol is mainly used as a pesticide intermediate to produce the insecticides fenitrothion, fenthionate, methiocarb, and permethrin. It is also an intermediate for color films, resins, and spices. Production method: m-nitrotoluene is reduced with iron powder to produce m-toluidine. The reaction formula is:

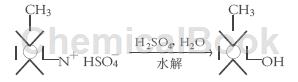

Use sodium nitrite solution to diazotize the amine group to produce diazonium salt. The reaction formula is:

Then diazonium salt is hydrolyzed to obtain m-cresol, the reaction formula is:

3) Synthesis of m-nitrobenzaldehyde

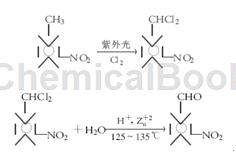

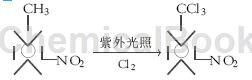

M-nitrobenzaldehyde is an intermediate in organic synthesis of medicines, dyes, surfactants, etc. It is used in the pharmaceutical industry for the production of calcium iopperate, iopanoic acid, m-hydroxylamine bitartrate, etc. The production method is generally halogenation first. Meta-nitrotoluene undergoes an electrophilic halogenation reaction under ultraviolet light. However, the presence of metals such as iron should be avoided. The main products are monohalogenated compounds, dihalogenated compounds and a small amount of trihalogenated compounds. The key to this reaction is to improve Dihalogenate selectivity. The reaction formula is:

Another relatively clean and advanced production method can use paired electrolytic oxidation to produce m-nitrobenzaldehyde. A lead plate is used as an electrode, a sulfuric acid solution of manganese sulfate is used as the anolyte, and a sulfuric acid solution of FeSO4 is used as the catholyte. Fenton’s reagent is obtained through electrolysis, and the methyl group on the aromatic ring is oxidized into an aldehyde group. And its yield is higher than that of chemical oxidation method. Due to paired oxidation, the current efficiency is higher than about 150%, which is worthy of promotion. its

4) Synthesis of m-aminobenzaldehyde

Meta-aminobenzaldehyde is an important organic synthesis intermediate. The production method is: oxidizing m-nitrobenzene to produce m-nitrobenzaldehyde. Then m-nitrobenzaldehyde is reduced. The catalysts can be sodium bisulfite and ferrous sulfate, or sodium disulfide can be used. The reaction formula is:

5) Synthesis of m-hydroxybenzaldehyde: m-hydroxybenzaldehyde is also an important organic synthesis intermediate. Production method: oxidize m-nitrobenzene to produce m-nitrobenzaldehyde, and then reduce m-nitrobenzaldehyde to produce m-aminobenzaldehyde. Use sodium nitrite solution to diazotize the amine group to produce a diazonium salt. The reaction formula is:

6) Synthesis of meta-aminotrifluorotoluene: meta-aminotrifluorotoluene is an important medium for dyes, medicines and pesticides

Intermediate body. Used in the manufacture of antipsychotic drugs such as fluorobenzidine, trifluoperazine, and trifluoperazine. Production method: m-nitrotoluene reacts with chlorine through ultraviolet illumination in the absence of iron and other metals to generate m-nitrotrichlorotoluene. Reaction formula:

7) m-nitrobenzoic acid: Using m-nitrotoluene and 10-12% nitric acid aqueous solution as the main raw materials, it is oxidized under the action of the catalyst ammonium metavanadate to generate m-nitrobenzoic acid and NO. Use one or two The first-stage absorption tower uses the method of cyclic absorption to absorb the NO discharged through the vent valve during the reaction process. The NO is oxidized into NO2 by air. The NO2 is then absorbed by water and becomes dilute nitric acid, which can be recycled and reused; the ammonium nitrate aqueous solution produced after absorption can be As a fertilizer for agricultural production, it is processed as a takeaway; through this three-level absorption and utilization, the basicZero emission is achieved above; the yield of m-nitrobenzoic acid in the method of the present invention can reach more than 85%, which is 15-25 percentage points higher than the existing technology, reducing the production cost; the purity of m-nitrobenzoic acid can reach 99.0 % or more, the by-products are significantly reduced; due to the use of catalysts, the reaction temperature and pressure are reduced, which greatly reduces energy consumption.

Main reference materials

[1] Dictionary of Chemical Substances

[2] Development and application research of downstream products of m-nitrotoluene

[3] CN201310639017.7 Process for preparing m-nitrobenzoic acid by catalytic oxidation method

微信扫一扫打赏

微信扫一扫打赏