Background and overview[1]

4-Methylpropiophenone is an important intermediate in the production of the drug Naomaining. Its synthesis mechanism is a Friedel-Crafts acylation reaction. However, due to the different substituents on the benzene ring of the raw materials toluene and ethylbenzene, its o-, Due to differences in the proportions of meta- and para-phthalate products, the selection of solvents, reaction times and temperatures in the production process are different.

Preparation[1]

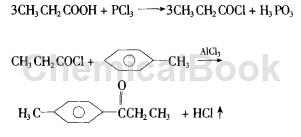

1) Synthesis process of propylphthalide chloride

Put 250kg propionic acid and 185kg phosphorus trichloride into a 500L glass-lined reaction pot respectively, slowly heat up the reaction, stir and keep at 50℃ for 6h, let stand for 3h, separate the lower layer of phosphorous acid, and obtain 297kg of propionic acid chloride. , the yield is 95%, and the obtained propylphthalide chloride can be used in the next step of production without purification.

2) Pour 225kg anhydrous aluminum trichloride and 160kg toluene into a 500L glass-lined reaction pot, cool it with a jacket, and slowly add 120kg propionyl chloride dropwise while stirring, keeping the internal temperature not exceeding 30°C. After the addition is completed , stir at room temperature for 1 hour, then slowly raise the temperature to 82°C, keep warm for 2 hours and then cool. Put the reaction liquid dropwise into a 2000L glass-lined reaction pot containing It ice-water mixture for low-temperature hydrolysis. Layer still, take the upper oily substance, add water and Wash with saturated soda ash solution until neutral, dry, remove toluene under normal pressure, and then collect the 96-100°C/930Pa fraction to obtain a content of greater than 98% 4-methylpropiophenone, with a yield of 88%.

Application[2-3]

Examples of application of 4-methylpropiophenone are as follows:

1) An acrylic double-sided tape, including a core tube, an adhesive and a PE base film, in which the adhesive is prepared from the following components, and the weight parts of each component are: isooctyl acrylate 60-70, acrylic acid 12-16, hollow glass beads 8-12, silica 7-9, dodecanethiol 2-3, nonionic surfactant 2-4, conversion agent 3-3.5, inorganic colorant 1.5-1.8, silica 0.20-0.25, isopropylthioxanthone 0.3-0.5, benzophenone 0.3-0.5, 4-methylpropiophenone 0.3-0.5, polyisobutylene 0.74-0.76, 1,6-hexanone Glycol diacrylate 0.12-0.14, defoaming agent 0.10-0.13, antioxidant BHT 0.15-0.17, flame retardant 0.74-0.76. The double-sided adhesive tape of the present invention has super strong adhesive force, annual heat resistance, weather resistance, sealing performance and buffering performance. It can be widely used on metal surfaces, wood, glass surfaces, power cabinets, rear-projection TVs or LCD TV screens, advertising signs, inner and outer sealing of sun roofs, etc.

2) An isooctyl acrylate adhesive, prepared from the following components by weight: 60-70 isooctyl acrylate, 12-16 acrylic acid, 8-12 hollow glass beads, and silica 7-9, dodecanethiol 2-3, nonionic surfactant 2-4, conversion agent 3-3.5, inorganic colorant 1.5-1.8, silica 0.20-0.25, isopropyl thioxanthone 0.3-0.5 , benzophenone 0.3-0.5, 4-methylpropiophenone 0.3-0.5, polyisobutylene 0.74-0.76, 1,6-hexanediol diacrylate 0.12-0.14, defoaming agent 0.10-0.13, antioxidant BHT0 .15-0.17, flame retardant 0.74-0.76, first stir the main ingredients fully, then add some auxiliary materials and stir again under UV light and nitrogen protection, finally add all the remaining auxiliary materials and stir thoroughly in the reactor. Can. The double-sided tape made with the adhesive of the present invention has super strong adhesive force, annual heat resistance, weather resistance, sealing performance and buffering performance. It is widely used in metal surfaces, wood, glass surfaces, power cabinets, rear-projection TVs or LCD TV screens, advertising signs, inner and outer sealing of sun roofs, etc.

Main reference materials

[1] Comparison of the production processes of 4-methylpropiophenone and p-ethylpropiophenone

[2] CN201210190497.9 Acrylic double-sided tape and its preparation method

[3] CN201210190498.3 Isooctyl acrylate adhesive and its preparation method

微信扫一扫打赏

微信扫一扫打赏