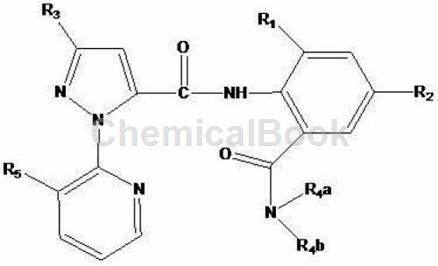

Background and overview[1][2]

Pesticides, especially agricultural pests, have developed varying degrees of resistance to existing pesticides. The development of new pesticides with different mechanisms of action is an important means to manage pest resistance. As people’s requirements for quality of life and health improve, research and development of efficient, safe, green and environmentally friendly pesticides has become an inevitable trend. DuPont disclosed anthranilamide compounds with insecticidal effects in CN1678192A;

2-Aminobenzonitrile compounds are useful chemical and pharmaceutical intermediates and are widely used in the synthesis of dyes, pesticides and medicines (Chinese Journal of Medicinal Chemistry, 2003, 13: 51-52). For example, tacrine, which is used to treat Alzheimer’s disease, can be obtained by reacting 2-aminobenzonitrile with cyclohexanone (Drugs, 1997, 53(8): 752-768); using 2-aminobenzonitrile and 1,3 -The condensation of cyclohexanedione to synthesize the tacrine derivative vernacrine (Drugs Fut., 1989, 14, 643); used for the synthesis of potential anti-malarial reagents (J. Med. Chem., 1973, 16: 1233- 1237) etc.

There are currently four main synthesis methods:

1. O-nitrotoluene is used as raw material, and anthranitrile is obtained through methylammonium oxidation and nitro reduction (Pharmaceutical Chemistry, 2002, 19: 211-212). This route requires high-temperature catalytic oxidation ammonia, and the catalyst is easy to Poisoning, long route, difficult to implement;

2. Aniline is used as raw material, and anthranitrile is obtained through multi-step reactions such as amino protection, nitration, nitrile decomposition, and reduction (Journal of Beijing Medical University, 1999, 31: 27-28). This route requires 4 steps of transformation. There are also high-temperature cyanolysis, etc., with low efficiency;

3. Isatin is used as raw material and is catalytically decomposed by copper-ammonium oxidation to obtain anthranitrile (Tetra. Lett., 1991, 32: 1008-1010). Although this route is short, it is decomposed by copper-ammonium oxidation catalytic The catalyst requirements are high and the yield cannot be guaranteed;

4. Isatin is used as raw material, first synthesize isatin-3-oxime, and then thermally decompose to obtain anthranitrile (Chemical World, 1998, 12: 635-636). This route is relatively optimal, but the high temperature catalytic heat When cracking isatin-3-oxime, the reaction is too violent and a large amount of carbon dioxide gas is produced, which is difficult to control and is particularly unfavorable for scale-up production. Therefore, it is very necessary to study a new production technology of 2-aminobenzonitrile.

Physical and chemical properties and structure[1]

2-Aminobenzonitrile is also known as 2-aminobenzonitrile; o-aminobenzonitrile; 2-amino-benzonitrile; o-aminobenzonitrile; 2-cyanoaniline; o-aminobenzonitrile; o-aminobenzyl Nitrile. 2-Aminobenzonitrile appears as light yellow crystals and the product is flammable; combustion produces toxic cyanide and nitrogen oxide smoke.

Preparation [2]

Method 1:

1) Weigh 5.88g of 2,3-indolinedione, 3.1g of hydroxylamine hydrochloride, and 45ml of water into a 250ml three-necked flask, reflux for 45 minutes, add 4g of sodium acetate at the end of the reflux reaction; The liquid is cooled to room temperature, filtered with suction, and washed twice with water; the filtrate is cooled, and a small amount of yellow crystals are precipitated, which is filtered again with suction. The two filter cakes are mixed and dried in an oven to obtain bright yellow 2,3-indoline bis. 6.22g of the crude ketone-3-oxime was recrystallized with a mixture of ethanol and water to obtain 6.03g of the product 2,3-indolinedione-3-oxime, with a yield of 92.99%;

2) Place 16.2ml of N,N-dimethylformamide in a 50ml three-necked flask, keep it at 0°C under an ice-salt bath, slowly add 2.4ml of POCl3 dropwise, and continue stirring for 3 minutes after the dropwise addition is completed. Slowly add 3.24g of 2,3-indolinedione-3-oxime at room temperature, continue to raise the temperature to 70°C, stir for 2 hours and then stop heating. After 2 hours of reaction, pour into crushed ice and let stand. If turbidity is generated, After filtration, adjust the pH of the filtrate to 9 with NaCO3, and extract with toluene three times; use a rotary evaporator to spin the solvent dry to obtain 2.93g of crude yellow oily substance N, N-dimethyl-N’-(o-cyanophenyl)formamidine. , yield 84.75%; dissolve the oily substance in ethyl acetate, and light yellow crystals precipitate one day later, and recrystallize with a mixed solvent of ethyl acetate and petroleum ether to obtain pure colorless crystals of N, N-dimethyl-N’ -(O-Cyanophenyl)formamidine 2.52g, yield 72.8%;

3) Place 0.42gN, N-dimethyl-N’-(o-cyanophenyl)formamidine, 1.32gZnCl2 and 12mL absolute ethanol in a 25mL single-neck flask, complete the reflux reaction for 5 hours, and evaporate the solvent to dryness , add water to dissolve ZnCl2, extract with ethyl acetate, and use a rotary evaporator to spin the solvent dry to obtain a pale yellow crude product 2-ammonium chloride.�� 0.26g of benzonitrile was recrystallized from a mixed solvent of methylene chloride and petroleum ether, and 0.24g of 2-aminobenzonitrile was precipitated as light yellow crystals with a yield of 83.92%; 2 was produced from 2,3-indolinedione -The overall yield of aminobenzonitrile was 56.81%.

Method 2:

Add 0.1 mol of isatin and 0.11 mol of hydroxylamine hydrochloride into a 500 mL three-neck flask, add 200 mL of dioxane and react in the same flow for 2-6 hours. After the reaction solution cools, add 15 mL of DMF and 0.15 mol of trichloride. Oxygen phosphorus, react at 70°C for 2-8 hours. After the reaction is completed, add 100 mL of water and heat to hydrolysis for 0.5-2 hours. After the reaction solution is cooled, filter it to obtain the crude product. After recrystallization from ethanol, the pure product was obtained with a yield of 82%.

Main reference materials

[1] Li Jiarong, Zhou Xinwo, & Chen Peng. (1998). One-pot synthesis of anthranitrile. Chemistry World (12), 635-636.

[2] Cao Feng, Ren Yong, & Hua Weiyi. (2002). Research on the synthesis of anthranitrile using different catalysts. Chinese Modern Applied Pharmacy, 19(3), 211-212.

[3] Xu Liangzhong, Wu Hualong, Feng Xianguo. (2012). Anthranilonitrile compounds and their preparation methods and uses. CN102391248A.

微信扫一扫打赏

微信扫一扫打赏