Background and overview[1]

2-Aminomethylbenzimidazole and its salt 2-(aminomethyl)benzimidazole dihydrochloride is a fine chemical raw material with wide application value. As a mild anti-corrosion agent for carbon steel, It is also an intermediate for the synthesis of benzimidazole Schiff bases, which have anti-swelling, antibacterial and other activities. The traditional synthesis method of 2-aminomethylbenzimidazole is to use HCl as a catalyst to react o-phenylenediamine and glycine through a multi-step heating and refluxing reaction. Its shortcomings include longer reaction time, more side reactions, and lower yield. A method for synthesizing 2-aminomethylbenzimidazole using o-phenylenediamine and glycine using HCl as a catalyst. This method requires heating and refluxing for 72 hours, but the highest yield is 56%. A method of synthesizing 2-aminomethylbenzimidazole using HCl as a catalyst, o-phenylenediamine and glycine as raw materials, and microwave irradiation. This method shortens the reaction time to 7 hours, and the maximum yield is 46%.

Preparation[1]

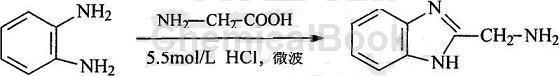

The synthesis method of 2-aminomethylbenzimidazole is to use o-phenylenediamine and glycine as raw materials, HCl as the catalyst, and use microwave intermittent irradiation to perform a condensation reaction to generate 2-aminomethylbenzimidazole in one step. 2-Aminomethylbenzimidazole further reacts with hydrochloric acid to form 2-(aminomethyl)benzimidazole dihydrochloride. The reaction equation is as follows:

The specific operation process includes the following steps:

A) Take o-phenylenediamine, glycine and 5~6mol/L HCl and add them to the flask in sequence. The molar ratio of o-phenylenediamine to glycine is 1:1~3, preferably 1:1.5~2.5 ; The molar ratio of o-phenylenediamine and 5~6mol/LHCl is 1:10~12. Stir evenly, put it into a microwave oven with a frequency of 2450MHz, and irradiate intermittently 6 times at an output power of 119W, 1 minute each time, to completely dissolve.

B) Intermittently irradiate the fully dissolved solution 10 times in a microwave oven at an output power of 119~280W, with each irradiation lasting 4~6 minutes followed by a 10-minute pause. Cool and precipitate solid, filter, wash with absolute ethanol, and dry to obtain a crude product.

C) The crude product is recrystallized with absolute ethanol to obtain 2-aminomethylbenzimidazole dihydrochloride. Dissolve it in water, adjust the pH to 8~9 with ammonia water, cool to 3~5°C, and allow The crystallization was complete and recrystallized from ethanol/water to obtain 2-aminomethylbenzimidazole with a maximum yield of 77%. 2-Aminomethylbenzimidazole further reacts with hydrochloric acid to form 2-(aminomethyl)benzimidazole dihydrochloride

Main reference materials

[1] CN200910022439.3 A method for synthesizing 2-aminomethylbenzimidazole by microwave irradiation

微信扫一扫打赏

微信扫一扫打赏