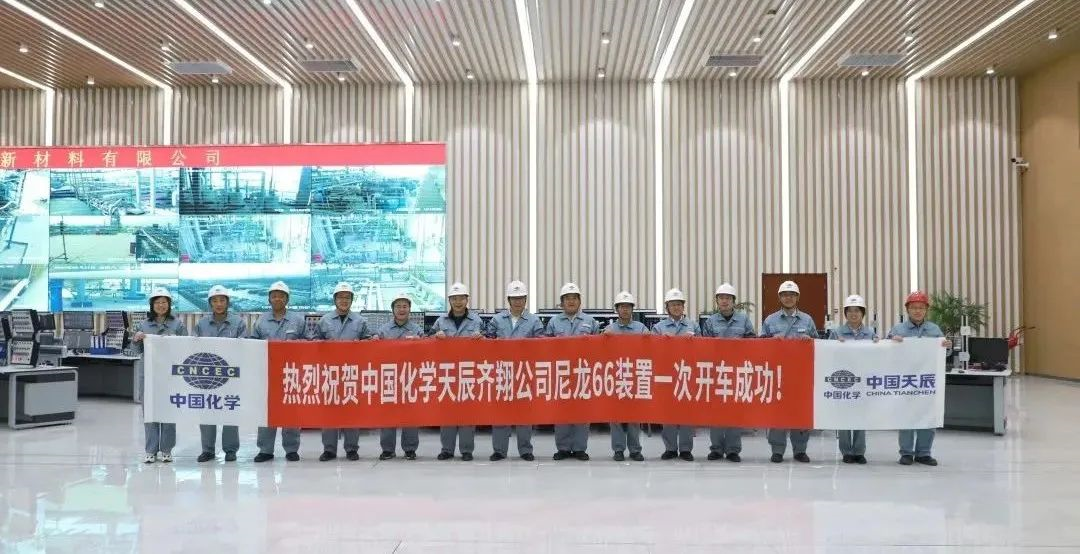

On February 11, the nylon 66 plant of the first phase of the nylon new material project of China Chemical Tianchen Qixiang New Material Co., Ltd. was successfully started up and produced the first batch of high-grade products. This is another successful start-up of China Chemical’s acrylonitrile, hexamethylenediamine and adiponitrile plants, marking the complete formation of a complete industrial chain system for the first phase of China Chemical Tianchen Qixiang Nylon New Material Industrial Base, which is a high-end Nylon new material industry clusters have laid a more solid foundation for chain aggregation and cluster development.

On March 22, 2022, the acrylonitrile plant of China Chemical Tianchen Qixiang successfully started up at one time

On March 31, 2022, the hexamethylenediamine plant of China Chemical Tianchen Qixiang successfully started up at one time

On July 31, 2022, China Chemical Tianchen Qixiang’s first set of “stuck neck” technology butadiene-based adiponitrile project was successfully put into production

It is understood that China Chemical Tianchen Qixiang Nylon New Material Project is located in Jinshan Industrial Park, Qilu Chemical Industry Zone. It adopts the direct cyanidation process of butadiene independently developed by China Chemical Tianchen Company, which has low raw material costs, less production pollution, and excellent process routes. The product has a wide range of uses, and it is the first industrial production project of adiponitrile by butadiene method in China, breaking the monopoly of foreign countries.

The project plans to invest 20 billion yuan, covering an area of about 3,000 mu. After completion, it will produce 1 million tons of new nylon materials, 500,000 tons of hexamethylenediamine, and 500,000 tons of adiponitrile in parallel with 500,000 tons of acrylonitrile.

The first phase of the nylon new material project invested 10.4 billion yuan, covering an area of 1,800 mu. Using butadiene as the main raw material, it produces 200,000 tons/year of adiponitrile, acrylonitrile, hexamethylenediamine, nylon 66 salt and slices and other products. After the first phase is put into production, the average annual revenue will exceed 10 billion yuan and the profit will exceed 2 billion yuan.

Nylon is closely related to life and is one of the five general-purpose engineering plastics. In the huge family of nylon materials, nylon 6 and nylon 66 are the two main varieties. Relying on its excellent comprehensive properties such as shock resistance, heat resistance, wear resistance and corrosion resistance, nylon 66 is widely used in civil yarn, industrial yarn, engineering plastics, aerospace and other fields. It is an ideal material for civilian clothing such as jackets and jackets, and is also an important material for realizing the lightweight of automobiles. It is widely used in automobile engines, electrical appliances, car bodies, high-speed rail car bodies, turbines, propeller shafts, screw propellers, and sliding bearings of large ships. application.

The successful commissioning of the nylon 66 plant at one time is of great significance to breaking the constraints of the transformation and upgrading of my country’s manufacturing industry. It will make up for the shortcomings of my country’s nylon industry chain, promote the technological upgrading of high-end nylon new materials, change the market supply pattern, and promote the healthy development of the industry. Key role.

微信扫一扫打赏

微信扫一扫打赏