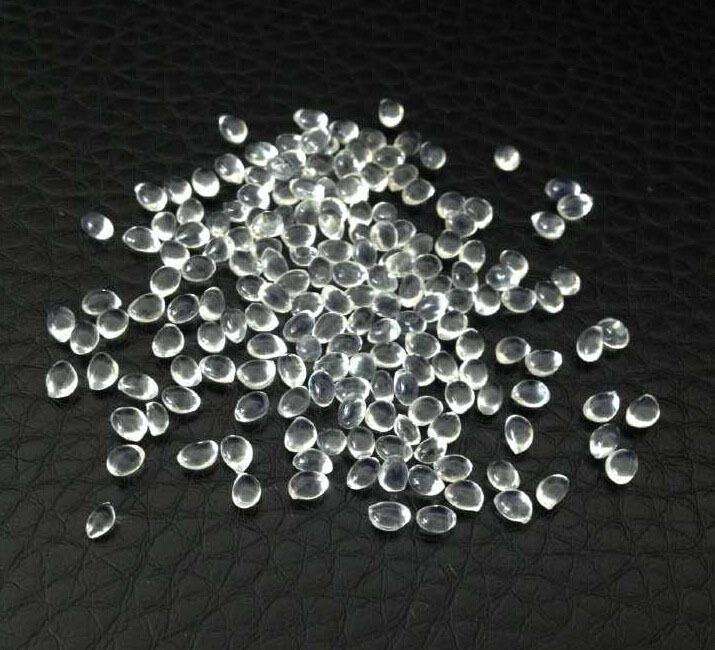

Thermoplastic rubber, referred to as TR, is a material between rubber and plastic. It has rubber elasticity at room temperature and can be used at high temperatures. Plasticized materials, part (or all) of the polymer chain of this material is a component that can show rubber elasticity, and there are constraining components inside the molecules that can form intermolecular cross-links at room temperature, and At high temperatures, the aggregation of these constrained components will melt or melt and become plastic.

The advantages of this material are as follows:

① It can be quickly formed using the molding machine used for thermoplastic resins without vulcanization;

② By changing the chemical structure of the raw materials, various elastomers with properties similar to soft vulcanized rubber to plastics can be produced;

③The elastomer produced is thermoplastic because it is not cross-linked, and the waste materials can be recycled. This product can be divided into the following categories according to the type of polymer.

(1) Polystyrene is mainly an SBS (styrene-butadiene-styrene) type thermoplastic polymer. Since the performance of this type of polymer is closest to that of rubber, it is the main type of thermoplastic rubber. Its molecule is composed of a cross-linked hard segment (polystyrene) and a rubbery soft segment (polybutadiene). This type of rubber is characterized by high strength, good elasticity, good low temperature properties, and good acid and alkali resistance. In addition, there is also a SIS (styrene-isoprene-styrene) type. In addition to the above characteristics, its weather resistance and heat resistance are also very good. This type of rubber is mainly used as soles, adhesives, plastic modified materials, asphalt modified materials, coatings and toys, etc.

⑵ Polyurethane is the general name for rubber-like elastic polymers with carbamate groups (—NHCOO—) in their molecular structure. Using bifunctional polyol, diol (or diamine), and diisocyanate as raw materials, it is composed of a soft segment (polyol-diisocyanate) and a hard segment (diol or diamine-diisocyanate). of copolymers. Changing the ratio of soft and hard chain segments can adjust the hardness and change the performance. This type of rubber has excellent mechanical strength, quality, and wear resistance, as well as ozone resistance and shock resistance. Mainly used for pipes, hoses, packings, liners, conveyor belts, etc. that require heat resistance, cold resistance, oil resistance, and hygiene. The most notable ones are used to make parts such as bumpers on cars.

(3) Polyolefins are made from ethylene and α-olefins as raw materials through coordination anionic polymerization and grafting reactions, or in olefin thermoplastic resins Mixed with some olefin rubber. The biggest characteristics of this type of rubber are its low relative density, wide operating temperature range of 120~50°C, good weather resistance, aging resistance, good resistance to chemicals and electrical energy, and can be arbitrarily colored, but poor adhesion and oil resistance. Mainly used in automobile parts, industrial supplies, wires and cables, etc.

(4) Polyester In this type of polymer, the hard segment is polyester with a high melting point and high crystallinity, while the soft segment is glassy. Polyethers with temperatures below -70°C. Change the ratio of polyester to polyether. Its physical and chemical properties have also changed. It is characterized by a wide temperature range, large load resistance, small creep, good bending fatigue resistance, good oil resistance and chemical resistance, good formability, and has the advantages of engineering plastics. Features, can be used as automobile parts, hoses, bearings, gears, wires and resin modified materials.

(5) Others mainly include ethylene-vinyl acetate copolymer, ethylene-acrylate structural polymer, polyethylene-butyl rubber joint copolymer, etc. These polymers can be used directly but are usually cross-linked with organic peroxides. Polyethylene-butyl rubber joint copolymer is obtained by jointing high-density polyethylene, low-density polyethylene and butyl rubber with an unsaturation degree of 1.4%. It has appropriate elasticity and is usually used in electrical applications due to its excellent electrical properties. Insulation Materials.

Thermoplastic rubber is the third generation of rubber after natural rubber and synthetic rubber. This type of rubber has obvious advantages in saving energy and manpower, so it has developed in recent years. It is relatively fast and is also being developed domestically. But from a technical perspective, there are still shortcomings. First of all, there is a problem of poor heat deformation resistance. The oil resistance and solvent resistance of polystyrenes need to be improved, and the thermal decomposition resistance, chemical resistance, and hydrolysis resistance of polyurethanes need to be improved, while polyolefins generally have poor properties.

Although polyesters have relatively comprehensive properties, due to incomplete separation of the constrained phase and the rubber phase, high stress occurs at low elongation.

微信扫一扫打赏

微信扫一扫打赏