Everyone knows that although defoaming agents are a relatively small industry in the chemical industry, there are many different types of defoaming agents and their functions. From a general perspective, defoaming agents mainly include water-soluble defoaming agents and oil-based defoaming agents. Everyone knows what a defoaming agent is, but may not know much about water-based and oil-based defoaming agents. Some people even ask this Are the two the same… Today, Kain Chemical will introduce to you the difference between water-soluble defoamer and oil-based defoamer?

Water-soluble defoamer

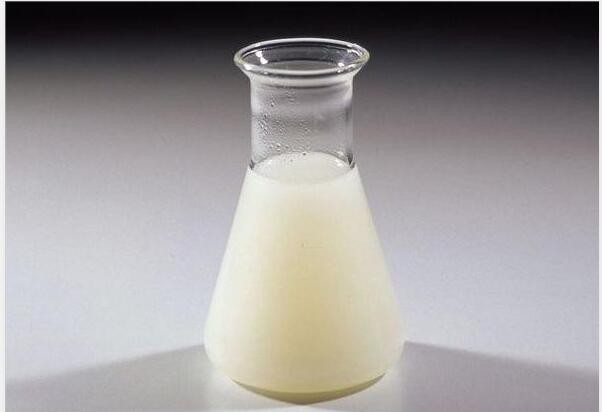

Water-soluble defoamer is a modified silicone polydimethylsiloxane high-efficiency defoamer emulsion that can be used to eliminate foam in aqueous systems. Because it is easily dispersed in water and can be well miscible with liquid products, it is not easy to break emulsions and float oil. It is a general-purpose broad-spectrum room-temperature defoamer. Suitable for use in water-soluble foaming systems, with good dispersion, good wettability, fast defoaming and strong foam suppression performance. It cannot be used in oily systems, as oil drift, suspended matter, etc. may occur.

Oil-based defoamer

Oil-based defoaming agent is a powerful liquid oil-based defoaming agent, specially designed for use in various oil-water systems. It has outstanding rapid defoaming and long-lasting foam suppression. , especially in oily systems, it has good dispersion, and is ideal for foam control in acid and alkali systems with temperatures above 200 degrees and about 20%. Suitable for use in oily foaming systems, with good dispersion, fast defoaming and strong foam suppression performance. It cannot be used in water-soluble systems, as it will cause incompatibility.

The difference between water-soluble defoamer and oil-based defoamer:

Water-based defoamer is a water-based system formed after emulsification with emulsifiers and other fillers. The raw materials used in the production process are non-toxic and harmless to the human body. It is especially suitable for defoaming in polyvinyl chloride resin, textile printing and dyeing, chemical reaction, petrochemical industry, metal processing industry, biological fermentation, water treatment, pharmaceuticals, and food fermentation industries.

Oil-based defoamer is not emulsified and is composed of mineral oil and polyether. It has outstanding anti-foaming and anti-foaming properties, especially good dispersion in oily systems, and is less affected by pH. Mainly used in various oil and water systems, such as synthetic resins, adhesives, adhesives, water reducing agents, phosphites, chemical synthesis, drilling mud, crude oil distillation, lubricants, etc…

Okay, after reading this sharing, do you know much about these two? In fact, there is a big difference between the two, but it cannot be said that water-based is better than oil-based. After all, both can be used in their respective fields.

微信扫一扫打赏

微信扫一扫打赏