[Alias] Orthophosphate

[Molecular formula]H3PO4

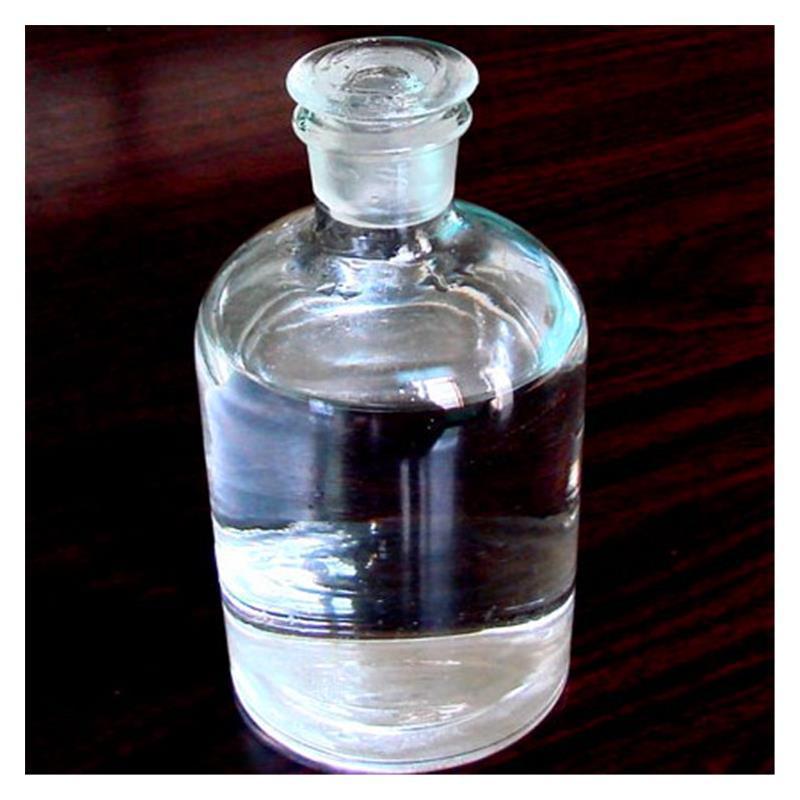

[Properties] Pure phosphoric acid is colorless rhombic crystals and becomes a viscous liquid. Density 1.834g/cm3, melting point 42.35℃. When it reaches the boiling point of 213°C (loses ½ H2O), it generates pyrophosphoric acid; when heated to 300°C, it becomes metaphosphoric acid. Easily deliquescent, soluble in water and ethanol. Its acidity is between strong acid and weak acid. It is weaker than strong acids such as sulfuric acid, hydrochloric acid and nitric acid, but stronger than acetic acid, boric acid, etc. The structure of the resulting acid and hydrate is a PO4 tetrahedron connected by hydrogen bonds. composed of. These hydrogen bonds remain in concentrated solutions and therefore exhibit viscosity. Commercially available phosphoric acid is a thick liquid containing 83%-98% H3PO4. The phosphate ions in the more dilute solution (54% H3PO4) form hydrogen bonds with water. Phosphoric acid has no oxidizing ability. But its acid properties. Can react with alkali, alkaline oxides and inorganic salts. Concentrated phosphoric acid irritates skin and mucous membranes. Hot concentrated phosphoric acid can corrode porcelain, so it can be stored in stainless steel containers.

[Use] Phosphoric acid is an important chemical intermediate product that can be made into many important products. In the fertilizer industry, it is used to make ammonium phosphate, heavy superphosphate, superphosphoric acid, precipitated phosphate fertilizer, etc. Inorganic chemicals are used to produce acid manganese phosphate, dipotassium hydrogen phosphate, disodium phosphate, potassium pyrophosphate and various phosphates. Refined phosphoric acid can be used to prepare calcium oxyphosphate for feed. In the pharmaceutical industry, it is used to produce pH adjusters for sodium glycerophosphate, iron phosphate, zinc phosphate and penicillin. In the food industry, it is used to produce glycerol calcium phosphate and acidic flavorings. The coating industry is used to produce metal anti-rust paint and flame retardant paint. Used as detergent additive in daily chemical industry. Used as catalyst in plastics and organic synthesis industries. It is used as chemical fire retardant finishing agent in the printing and dyeing industry. It is used in light industry, electromechanical and instrument industries to prepare phosphating liquid and perform phosphating treatment on the surface of metal parts. In addition, it is also used as latex coagulant, safety match impregnating agent, pH adjuster, electrochemical aluminum coating rust inhibitor, as well as preparing electroplating solutions, preparing pigments, etc.

[Brief preparation method]

①There are two types of industrial production: wet method and thermal method. The wet method is obtained by decomposing phosphate rock using inorganic strong acids (sulfuric acid, hydrochloric acid, nitric acid). It can be divided into sulfuric acid method, hydrochloric acid method, nitric acid method and ammonium bisulfate method, etc. The sulfuric acid method is commonly used. The thermal method uses yellow phosphorus as raw material and is produced through oxidation and absorption. The concentration of phosphoric acid produced by the mixed method is lower. It contains many impurities and needs to be purified; the phosphoric acid produced by the thermal method has high concentration and purity, but consumes a lot of power and has high investment and cost.

② When preparing a small amount of pure phosphoric acid for laboratory use, industrial phosphoric acid can be used as raw material, heated to about 80°C, and hydrogen sulfide is introduced until it is saturated to remove arsenic and heavy metals. A sulfide precipitate is generated. After filtering to remove the precipitate, it is heated and concentrated below 150°C to drive out hydrogen sulfide and hydrogen chloride. If the phosphoric acid produced is still slightly yellow, a small amount of potassium permanganate can be used for decolorization.

[Safety and Protection] Phosphoric acid is a secondary inorganic acidic corrosive substance, hazard regulation number: 93002. Packed in polyethylene plastic barrels, net weight per barrel is 25kg, 30kg or 35kg. Small packages of 0.5kg and 1.5kg can be packed in small-mouth glass bottles, and there should be a “corrosive substance” mark on the packaging. Cover wooden box when transporting. High-concentration phosphoric acid should be protected from freezing when it is cold to prevent the container from breaking. Do not store or transport together with alkaline items and other corrosive items.

Phosphoric acid vapor can irritate the nasal mucosa and be corrosive to the skin. If the skin comes into contact, rinse immediately with plenty of water and apply mercurochrome or gentian violet solution to the affected area.

微信扫一扫打赏

微信扫一扫打赏