Lightweight, highly durable fiber-reinforced epoxy composites, composed of glass or carbon fibers embedded in a polymer matrix, are high-performance materials critical to the manufacture of automobiles, ships, aircraft and wind turbine blades Material.

By 2025, approximately 25,000 tons of wind turbine blades will reach the end of their operational life each year. Traditionally, wind turbine blades have been difficult to recycle due to the chemical properties of epoxy, which is an elastomeric substance and is considered impossible to break down into reusable components. Epoxy resins are not biodegradable and release toxic gases when incinerated, ultimately leading to landfill being the primary way to dispose of them.

Landfilling of wind turbine blades has been banned by several European countries due to inefficiency and unsustainability, with more expected to follow. Therefore, there is an urgent need for viable recycling strategies for epoxy resins and their composites.

The newly discovered process is a proof-of-concept for a recycling strategy that can be applied to the vast majority of existing wind turbine blades and blades currently in production, as well as other epoxy-based materials.

The results were published in the leading scientific journal Nature, and Aarhus University, together with the Danish Institute of Technology, patented the process.

Specifically, the researchers showed that by using a ruthenium-based catalyst and the solvents isopropyl alcohol and toluene, they could separate the epoxy resin matrix and release one of the original building blocks of the epoxy polymer, bisphenol A, and an intact glass fiber into a single the process of.

However, the method is not immediately scalable because the catalytic system is not efficient enough for industrial implementation—and because ruthenium is a rare and expensive metal. Aarhus University scientists are therefore continuing to improve the method.

“Nonetheless, we believe this is a major breakthrough in developing durable technologies that can create a circular economy for epoxy-based materials. This is the first publication of a chemical process that can selectively break down epoxy resin composites and separate out the most important materials One of the lead authors of the study

“The epoxy polymer is an important component as well as the glass or carbon fiber, without damaging the latter in the process,” says Troels Skrydstrup.

Troels Skrydstrup is a member of the Department of Chemistry and the Interdisciplinary Center for Nanoscience (iNANO) at Aarhus University

professor. The research was supported by the CETEC project (Circular Economy of Thermoset Epoxy Composites), a partnership between Vestas, Olin AG, the Danish Institute of Technology and Aarhus University.

In this study, the researchers used a Ru-catalyzed dehydrogenation/bond cleavage/reduction tandem reaction to break the most common C (alkyl)-O bond in the polymer, which can be used to break the BPA matrix phase. neighboring

C(alkyl)-O

single bond. The researchers demonstrated application of this method to unmodified amine-cured epoxy resins as well as commercial composites, including the casings of wind turbine blades. The researchers’ results show that chemical recycling of thermoset epoxy resins and composites is feasible.

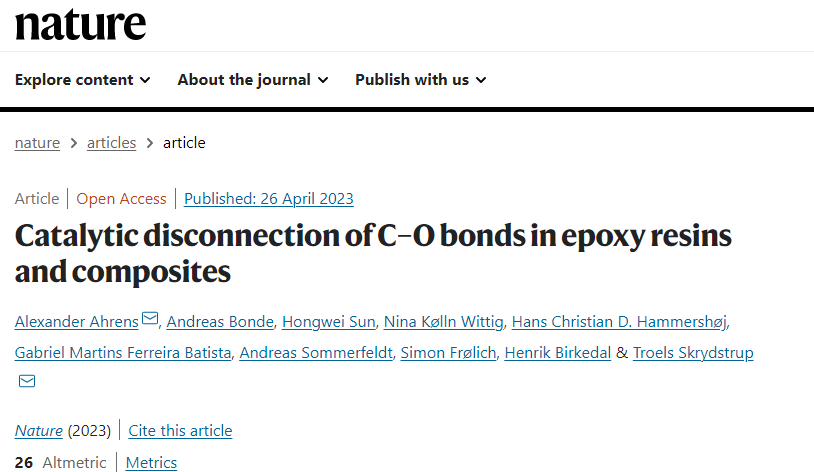

The catalytic deconstruction experiment of epoxy resin proved that 81% of the BPA amount can be recovered in 4 days of catalytic reaction.

Figure 1 Catalytic deconstruction of epoxy resin

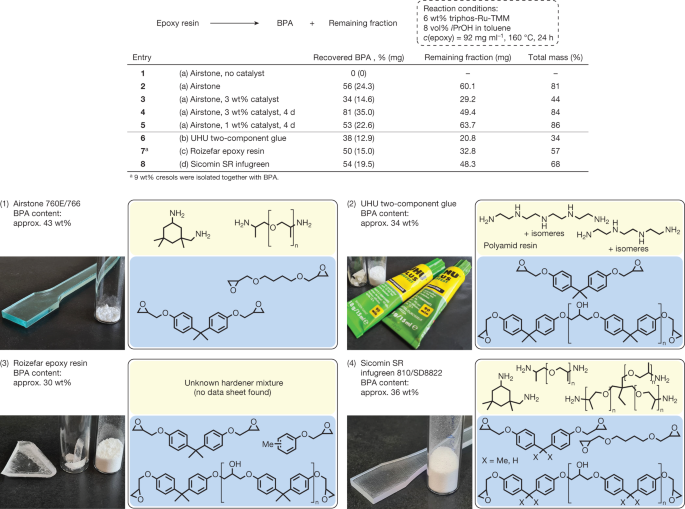

With a general method available for the molecular decomposition of amine-cured epoxy resins, the researchers turned to investigate the applicability of this protocol to the deconstruction of fiber-reinforced epoxy composites that contain high weight percent fibers in addition to the polymer matrix. Without any preprocessing, 3

After days, the composite material clearly separated into loose fibers. The reaction mixture was decanted; after washing, 57 wt% of the carbon fibers were recovered and 13 wt% of BPA was separated from the solution.

A follow-up test was conducted on the casing of a state-of-the-art retired wind turbine blade. This commercial composite sample was completely decomposed after catalysis to obtain 50wt% glass fiber and 19wt% BPA.

Figure 2 Recycling of BPA and fibers from commercial epoxy composites using Ru catalysis

In conclusion, a circular economy can be considered for components recovered from end-of-life composite materials. The high-purity bisphenol A recovered from recycling can theoretically be reused in existing production chains such as epoxy resin, polycarbonate or polyester, replacing original BPA produced from petroleum raw materials. The researchers’ catalytic process can be viewed as a proof-of-concept that it is possible to achieve a circular economy for these valuable and relevant materials.

微信扫一扫打赏

微信扫一扫打赏