In January, Cangzhou Dahua Group Company’s “Cangzhou Dahua Lean Production and Operation Scenario Supported by Digital Technology” passed all the way in the “First State-owned Enterprise Digital Scene Innovation Professional Competition” of the State-owned Assets Supervision and Administration Commission of the State Council, and ranked among the best in the preliminary competition. Stand out from more than 3,000 participating scenes across the country and advance to the national finals.

In order to thoroughly implement the decision-making and deployment of the Party Central Committee and the State Council on accelerating digital development, and promote the digital transformation of state-owned enterprises in depth, the Science and Technology Innovation Bureau of the State-owned Assets Supervision and Administration Commission of the State Council held the first “State-owned Enterprise Digital Scene Innovation Professional Competition”. As a large-scale chemical enterprise, Cangzhou Dahua’s digitalization work looks at the world, benchmarks first-class, firmly takes the road of independent innovation, continuously explores and innovates, and realizes a great leap in digital transformation. Cangzhou Dahua’s shortlist this time reflects that the group company is upgrading traditional industries through digitization, networking, and intelligent transformation, and has created a benchmark scene for the digital transformation of the chemical industry.

The system platform of “Cangzhou Dahua Lean Production Operation Scenario Supported by Digital Technology” uses digital means to centrally integrate the dispatching room and the general control room of each device into the newly built modern large-scale central control center.

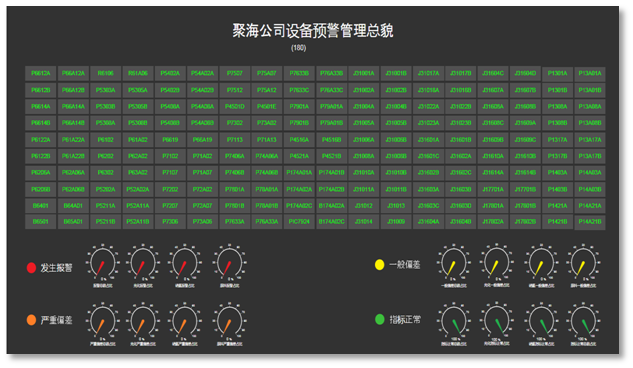

The management level has been reduced from 10 to 3, and a production management and control platform with MES as the core has been established, and the production process indicators and equipment operation status overview map have been implemented, and the color changes of the red, orange, yellow and green areas reflect the operation of the indicators and remind personnel at all levels Intervene and adjust in time. Through the management of four areas, the frequency and quantity of alarms have been greatly reduced, and the number of alarms has dropped by nearly 90%. Independently developed the AOAS “General Control Intelligent Assisting System”, which changed the original operation mode based on experience through data triggering behavior. The DCS monitoring period was reduced from more than 10 minutes to 2 seconds for intelligent monitoring, which greatly reduced labor intensity. and complexity, the frequency of operations has dropped by 85%.

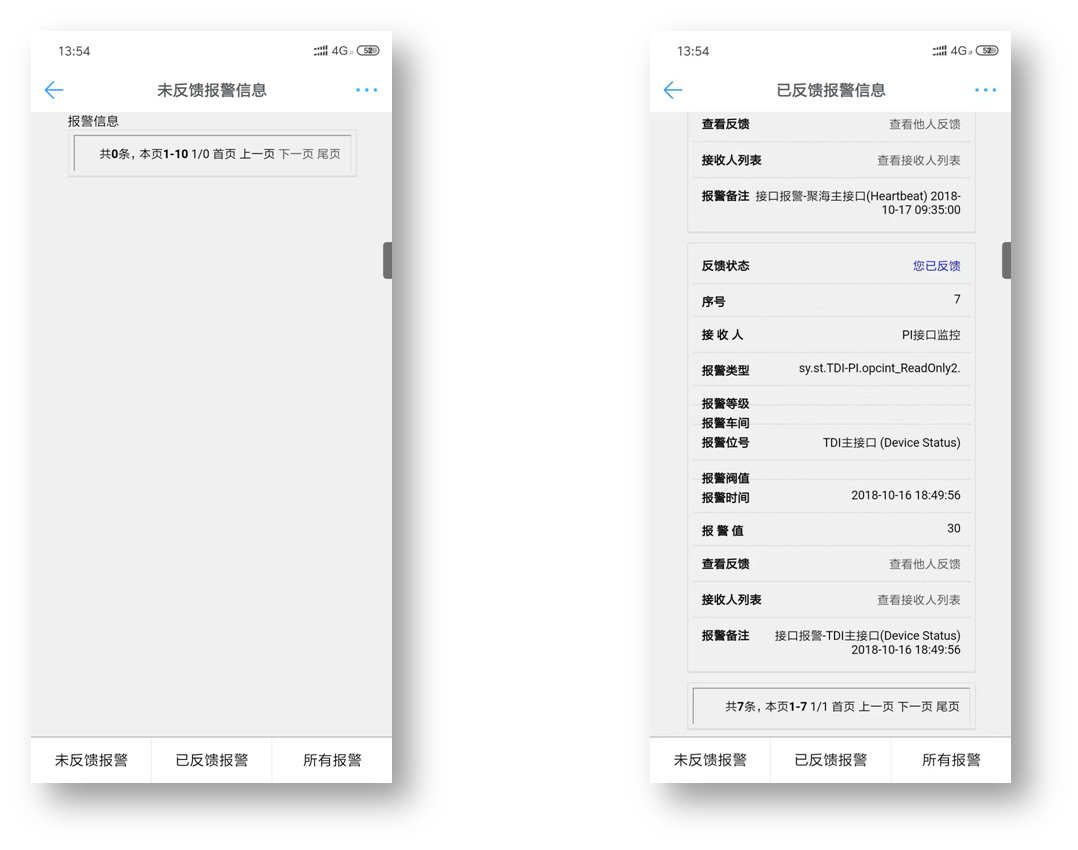

Promote the full life cycle management of equipment based on digitalization, change the original sub-specialty management and planned maintenance mode, and integrate static information such as equipment files, maintenance, and spare parts with dynamic information such as vibration, temperature, current, inspection, and abnormal process indicators. Integrate to form equipment status evaluation results, dynamically grasp equipment operation status through data, implement preventive maintenance, and realize integrated management of equipment. A new visual and intelligent inspection mode has been established to implement standardized management of inspection lines and tasks. The inspection information is pushed to relevant professional management personnel in the form of numbers, pictures and videos, and the inspection situation is analyzed and judged from multiple angles to achieve Standardization, normalization and digitalization of on-site inspection management.

Cangzhou Dahua will take this professional competition as an opportunity to promote the deep integration of digital technology and the real economy, focus on goal-leading, innovation-driven development, and empowerment of industrial upgrading. We will draw a map of the digital scene innovation in the chemical industry with the spirit of “working hard” and promote the digitalization of enterprises in an all-round way.

微信扫一扫打赏

微信扫一扫打赏