Background and overview[1][2]

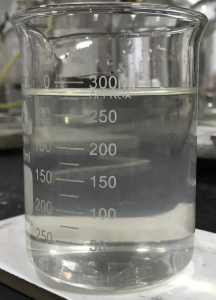

Ethylbenzene is insoluble in water, a colorless and flammable liquid, soluble in alcohol, benzene and ether. Used in styrene production, synthetic polymers, and also as solvent or diluent. This product is of low toxicity. It can be absorbed through the respiratory tract, digestive tract and skin. Acute inhalation of 4.92g/m3~9.84g/m3 can cause acute poisoning, symptoms of eye and nose irritation, fatigue, dizziness and chest tightness. At 24.6g/m3, it is unbearable. In severe cases, nausea, vomiting, staggering gait, coma, and encephalopathy and toxic liver disease may occur. Direct inhalation of this product can cause pulmonary edema or chemical pneumonitis. Long-term exposure to 492 mg/m3 for 8 hours a day can cause chronic effects, mainly causing neurasthenic syndrome, respiratory tract irritation symptoms, and leukopenia. Frequent direct contact with skin can cause roughness, cracking and peeling. During the production process, pay attention to respiratory protection and skin contact protection on hands and face.

Preparation method[2]

① Using benzene as raw material and aluminum trichloride as catalyst, ethylbenzene can be produced by reacting with ethylene.

② Ethylbenzene can be produced by using benzene as raw material, silicon oxide as carrier, and alumina as catalyst, reacting with ethylene at high temperature and high pressure.

③Ethylbenzene can be produced by using benzene as raw material, diatomite and phosphoric acid as catalyst, and performing multi-stage catalytic reaction with ethylene.

The above three methods all use benzene as raw material and use catalytic method to react with ethylene. The reaction is carried out under high temperature and high pressure.

④ Ethylbenzene can also be produced by selective alkylation using olefin-containing waste gas and aromatic hydrocarbons as raw materials and using boron trifluoride as a catalyst.

⑤ Ethylbenzene can be produced by using hydroxyethylbenzene as raw material and trifluoroacetic acid and triethylsilane as catalyst.

Application Report[3-4]

CN201210392996.6 reports a method for the alkylation of ethanol and ethylbenzene to synthesize p-diethylbenzene. It mainly solves the problem of p-diethylbenzene in the alkylation reaction of ethanol and ethylbenzene to synthesize p-diethylbenzene in the existing technology. The problem of low selectivity and low yield of ethylbenzene. Para-diethylbenzene is an essential resolving agent in the adsorption and separation process of para-xylene, and its synthesis has very important social benefits and practical value. In the present invention, ethylbenzene and ethanol are used as raw materials and a gas inert to the reaction is used as a carrier gas. The reaction temperature is 300~450°C, the reaction pressure is 0~1 MPa, and the space velocity is 1~10 hours. sup>-1, the molar ratio of ethylbenzene to ethanol is (10:1)~(1:2), and the molar ratio of carrier gas to the total amount of ethylbenzene ethanol is (1:1)~(5: Under the conditions of 1), the technical solution of contacting the reaction raw materials with the catalyst to generate p-diethylbenzene and water solves this problem well and can be used in the industrial production of the alkylation reaction of ethanol and ethylbenzene to synthesize p-diethylbenzene. .

CN201210324476.1 reports a method for synthesizing para-diethylbenzene from ethylbenzene and ethylene, which mainly solves the problem of low selectivity for para-diethylbenzene in the existing technology. The present invention uses ethylbenzene and ethylene as reaction raw materials, at a reaction temperature of 180~400°C, a reaction pressure of 0.1~4.0MPa, and an ethylene weight space velocity of 0.1~2.0 hours -1, ethylbenzene Under the condition of /ethylene molar ratio of 2 to 10, the reaction raw materials are contacted with the catalyst to generate p-diethylbenzene; the catalyst includes the following components in parts by weight: a) 40 to 80 parts of SiO2/Al2O3 molar ratio of 10 to 100; b) The technical solution of 20 to 60 parts of binder is better solved This problem can be used in the industrial production of ethylbenzene and ethylene to produce p-diethylbenzene.

Main reference materials

[1]Hygiene Dictionary

[2] Practical Fine Chemical Dictionary

[3]CN201210392996.6 Method for synthesizing p-diethylbenzene through alkylation of ethanol and ethylbenzene

[4]CN201210324476.1 Method for synthesizing p-diethylbenzene from ethylbenzene and ethylene

微信扫一扫打赏

微信扫一扫打赏