Background and overview[1]

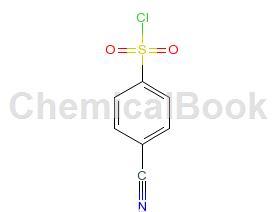

(4-Cyanophenyl)methanesulfonyl chloride can be used as a pharmaceutical synthesis intermediate, mainly used in laboratory research and development processes and chemical and pharmaceutical synthesis processes. Sulfonyl chloride is an important type of organic and pharmaceutical synthesis intermediates and raw materials, which can be used to synthesize drug molecules with sulfonyl groups. Sulfonamides can be obtained by reacting sulfonyl chlorides with amines, and sulfonamides are the active structural units of many drugs. Among the various current synthesis methods of sulfonyl chlorides, the synthesis method using S-alkylisothiocarbamide salts as raw materials is relatively economical and environmentally friendly, because S-alkylisothiocarbamide salts are non-toxic, tasteless and will not cause any environmental impact. Pollution will not cause harm to the human body.

S-Alkyl isothiocarbamide salts can be conveniently prepared by nucleophilic substitution of thiourea with alkyl halides, sulfate esters or sulfonate esters. The preparation of alkylsulfonyl chlorides from S-alkylisothiouronium salts can be achieved by oxidative chlorination. The reported oxidative chlorination reagents mainly include chlorine gas, hydrogen peroxide-hydrochloric acid, potassium permanganate-hydrochloric acid, iodobenzene oxide-HCl-silica gel, N-chlorosuccinimide-hydrochloric acid, etc. However, chlorine has the disadvantages of high toxicity, poor safety, and inconvenient measurement and operation in the laboratory; potassium permanganate is seriously polluted, and the dosage is larger (4.5 times), and the yield is not ideal; hydrogen peroxide-hydrochloric acid When making oxidative chlorination reagents, the dosage of hydrogen peroxide and hydrochloric acid is also large; iodobenzene oxide is more expensive, inconvenient to operate, and is not suitable for large-scale preparation; the N-chlorosuccinimide-hydrochloric acid method will also Organic by-products are produced.

Preparation[1]

The preparation of (4-cyanophenyl)methanesulfonyl chloride is as follows: add thiourea (0.387g, 5mmol) and p-nitrobenzyl chloride (0.633g, 5mmol) into 5mL of ethanol, and reflux for 30 minutes. The solvent was removed under pressure to obtain S-benzylisothiourea salt as a white solid. Slowly add the white solid directly to 6MH2SO4 (2mL, 12mmol), then add diethyl ether (30mL), slowly add 30mL of newly shipped 5% NaClO solution under ice-water bath conditions, and control the temperature in the reaction system to be between 10-20oC. . After the addition is completed, continue the reaction for 15 minutes. After the reaction, the liquids were separated, and the organic phase was dried with anhydrous Na2SO4, and the solvent was evaporated to obtain the product (4-cyanophenyl)methanesulfonyl chloride, colorless crystals, melting point 92-94°C, 0.886g, yield 93%. 1HNMR(400MHz, CDCl3) δ7.61-7.35(m,4H), 5.12(s,2H).

Main reference materials

[1] CN201310305294.4 A simple method for preparing sulfonyl chloride

微信扫一扫打赏

微信扫一扫打赏