Background and overview[1][2]

P-Toluic acid is mainly used to manufacture hemostatic aromatic acid, p-carbonitrile, p-toluoyl chloride, photosensitive materials, etc., and is used as an organic synthesis intermediate and in the pesticide industry to prepare the fungicide phosphoramide.

Preparation[1]

Most of the existing synthesis methods use concentrated nitric acid to oxidize p-xylene and react for 30 hours to produce p-toluic acid with a yield of 58%. Since this synthesis method requires the use of concentrated nitric acid as the reactant, the risk factor during the synthesis process is high, the corrosion resistance of the equipment is high, and the maintenance cost of the equipment is high, which is not conducive to reducing the overall production cost, and the synthesis process takes more than 30 hours. The production time is too long, and the final yield is not high, only about 58%. Therefore, it is necessary to propose a new synthesis method.

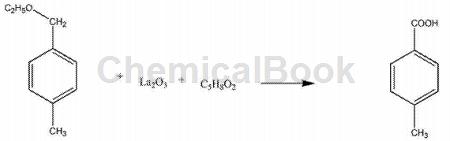

CN201710530837.0 proposes a synthesis method for the hemostatic aromatic acid drug intermediate p-toluic acid, which includes the following steps:

A: Add 4-methyl-toluene ether and 1.5L potassium chloride solution to the reaction vessel, control the stirring speed to 230-260rpm, raise the solution temperature to 30-38°C, continue the reaction for 60-90min, and add oxidizing agent For lanthanum powder, raise the temperature to 40-46 ℃ and react for 2-3 hours;

B: Then add methyl crotonate solution, raise the temperature to 50-55°C, control the stirring speed to 310-350rpm, react for 90-130 minutes, lower the temperature to 10-15°C, add 1.6L potassium sulfate solution, The solution is separated into layers, washed with nitrile solution, washed with p-chloronitrobenzene solution, recrystallized in dihexylamine solution, and dehydrated with a dehydrating agent to obtain the finished product p-toluic acid.

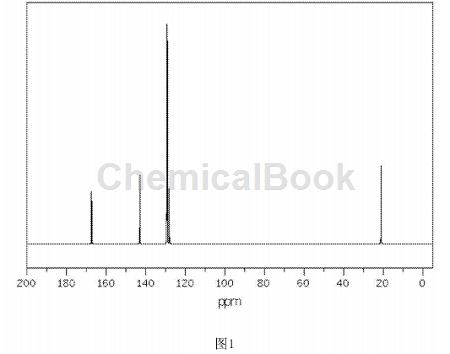

The synthesis method of the hemostatic aromatic acid drug intermediate p-toluic acid provided by this method does not require the use of concentrated nitric acid as a reactant, which reduces the risk factor in the synthesis process, reduces the corrosion resistance requirements of the equipment, and reduces It reduces equipment maintenance costs and helps reduce overall production costs. The synthesis process only takes a few hours, the production time is accelerated, the reaction intermediate links are reduced a lot, the reaction time is also shortened a lot, and the reaction yield is also improved. At the same time, the invention provides A new synthetic route was developed, which laid a good foundation for further improving the reaction yield. Figure 1 is the 13 CNMR analysis spectrum of the finished product p-toluic acid.

Apply [3-5]

1. Used in the synthesis of 2,6-dichloro-p-toluic acid

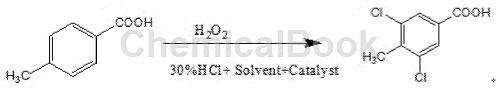

2,6-Dichloro-p-toluic acid is an important intermediate for the pesticide and fungicide Zoxamide. Zoxamide is a benzene developed by Rohmhas (now Dow Agricultural Sciences). Formamide protective fungicide has a novel mechanism of action and can effectively prevent and control diseases caused by Oomycetes on fruit trees and vegetables, including grapes and potatoes, such as potato and tomato late blight, cucumber downy mildew and It is also effective against grape downy mildew. 2,6-Dichloro-p-toluic acid is an essential intermediate in the synthesis of benzofen. CN201610232865.X provides a process method for 2,6-dichloro-p-toluic acid that is simple to operate, has low production cost, and is easy to be industrially produced. of the present inventionThe reaction route is as follows:

The present invention provides a method for synthesizing 2,6-dichloro-p-toluic acid using p-toluic acid as raw material through oxidative chlorination reaction, which specifically includes the following steps: first, p-toluene Formic acid is dissolved in the solvent dichloroacetic acid, and then the tungstate catalyst and hydrochloric acid are added in sequence to raise the temperature, and then hydrogen peroxide is added dropwise to perform an oxidative chlorination reaction. After 10 hours of reaction, the reaction solution is concentrated, and then methanol is added for recrystallization. , to obtain the product 2,6-dichloro-p-toluic acid,

2. Used in the synthesis of p-toluoyl chloride

With the rapid development of polymer materials, p-toluoyl chloride has gradually become an important chemical intermediate and has attracted more and more attention from researchers. Its excellent properties are widely used in medicines, pesticides, dyes and photosensitizers. It has been widely used in material production and other aspects. CN201510931007 provides a continuous production process of p-toluoyl chloride, which has the characteristics of simple process, short production cycle and high product yield. The continuous production process of p-toluyl chloride according to the present invention is to add p-toluic acid and thionyl chloride into a reaction kettle to react in the presence of a phase transfer catalyst to obtain a reaction liquid, and then The reaction liquid is added to the distillation tower for atmospheric distillation to recover the thionyl chloride therein to obtain crude p-toluoyl chloride. The crude p-toluoyl chloride is added to a thin film evaporator for vacuum distillation. Obtain p-toluoyl chloride.

3. Used to prepare fluorescent whitening agent OB-1

Fluorescent whitening agent, also known as white dye, can improve the whiteness and gloss of substances. It has the best heat resistance among all whitening agent products. It not only has high decomposition temperature, good whiteness, and small dosage, It also has good compatibility with additives in plastics and is widely used in textiles, printing and dyeing, papermaking, plastics, paints, and decorative materials. 4,4′-Bis(benzoxazol-2-yl)stilbene (OB-1) is an oxazole-based fluorescent whitening agent. It has excellent co-fastness, dye resistance, and acidity. , whitening effect, its melting point exceeds 350°C, and has good heat resistance and light resistance. It has been widely used in the plastics and textile industries, and also has many applications in photosensitivity.

In order to solve the problems existing in the existing synthetic process of fluorescent whitening agent OB-1, CN201610263921.6 provides a new OB-1 synthesis process. The raw materials are cheap and easy to obtain, and the product has high purity, excellent color and quality. Better. Includes the following steps:

(1) Use 2-benzoxazolone and p-toluic acid as raw materials, use boric acid as a catalyst in the solvent, react at 170~220°C for 8~15 hours, and then remove the solvent by distillation to obtain 4-( Methylphenyl)benzoxazole;

(2) Use 4-(methylphenyl)benzoxazole and sulfur prepared in step (1) as raw materials, react at 240-270°C for 3-5 hours, and remove the hydrogen sulfide generated by the reaction while reacting , after the reaction is completed, use xylene to desulfurize, and then refine it through trichlorobenzene to obtain the fluorescent whitening agent OB-1.

The OB-1 synthesis method provided by the present invention has a simple synthesis process, the raw material p-toluic acid is cheap and easy to obtain, has few by-products, high product purity and yield, excellent product color and better quality.

Main reference materials

[1] CN201710530837.0 Synthesis method of hemostatic aromatic acid drug intermediate p-toluic acid

[2] CN201610232865.X A synthesis method of 2,6-dichloro-p-toluic acid

[3] CN00112102.2 Method for analyzing the content of p-toluic acid and p-carboxybenzaldehyde in organic solutions

[4] CN201510931007.X Continuous production process of p-toluyl chloride

[5] CN201610263921.6 A synthesis method of fluorescent whitening agent OB-1

微信扫一扫打赏

微信扫一扫打赏